Products

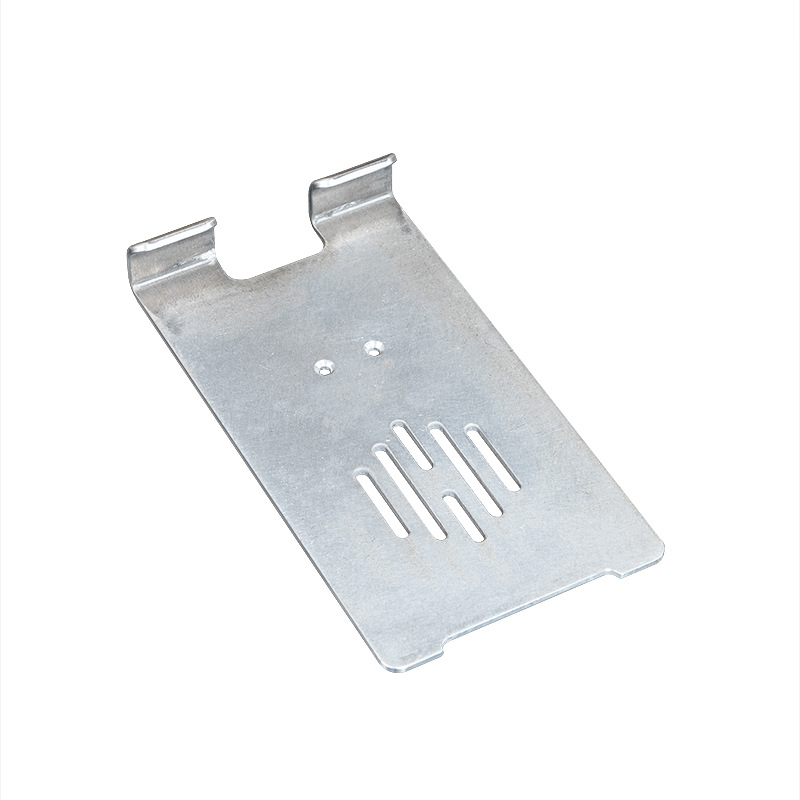

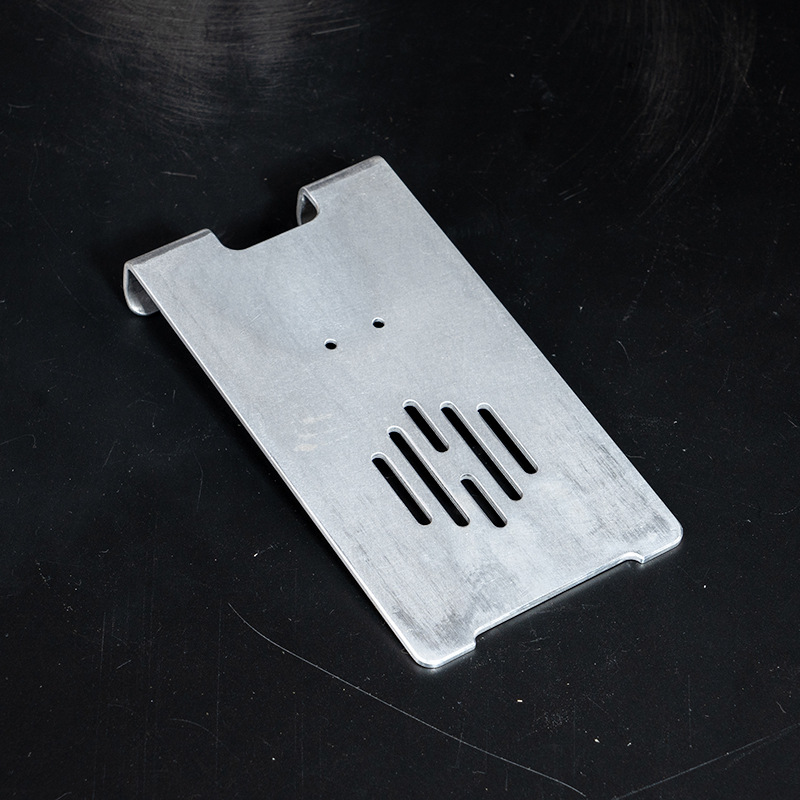

Aluminum custom stamping and bending automobile chassis guard plate

Aluminum bending car chassis guard plate Information | |

Name | Metal bending and stamping/automobile chassis guard plate/custom aluminum alloy parts |

Size | Customization |

Type | Home appliance parts stamping parts |

Price | Negotiation |

Mold type | Progressive die, continuous die, process die, compound die |

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process | Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | Automotive stamping parts, door hinges, brackets, stoppers, reflectors, shielding covers, alloy guide rails, beryllium copper shrapnel, LED lamp housings, metal connectors, special-shaped stamping parts, stainless steel shrapnel, electrical housings, chassis sheet metal, connectors, radiators, metal cans, gift boxes, food trays, canteens |

Popular Keywords

Automobile chassis, automobile chassis stamping, automobile chassis customization, aluminum bending, metal bending, aluminum alloy parts, automobile guard plate customization, metal parts, OEM parts, motorcycle stamping, OEM sheet metal manufacturing, metal stamping services, deep drawing services, metal stamping

Stamping characteristics

Xuanmin offers a range of stamping design features to meet your unique requirement. Stamping design features include:

Advantages of automotive stamping

Large-scale production efficiency: Automotive manufacturing typically involves producing large quantities of identical parts.

Cost-effective production: Once the stamping die is set up, the process can quickly produce large quantities of automotive parts, making it more cost-effective.

Diversity of material use: Stamping is compatible with a wide range of materials, including a variety of metals and alloys commonly used in the automotive industry

Complex component production: Vehicles often contain complex components with specific shapes and features. Stamping can produce complex components such as body panels, brackets, and structural components.

High precision and consistency: Using precision dies and presses ensures that each stamped part meets strict dimensional specifications, thereby improving the overall quality of automotive components.

Tool Design and Manufacturing

Our team of engineers designs and produces tooling for progressive metal stamping production in-house, using highly customized, state-of-the-art Siemens NX 3D CAD modeling software. This ensures maximum productivity and cost efficiency for our customers’ projects, especially reducing costs typically associated with changes during the design phase.

Processing Process

Xuanmin has a strict process for producing high-quality molds, CNC machined parts and samples. The process involves several key stages, including programming, raw material selection, CNC machining, quality inspection, surface treatment, retesting, packaging and shipping. This multi-step approach ensures that the products meet strict quality standards throughout the production process. The company also emphasizes quality control from IQC to OQC, further demonstrating their commitment to producing reliable and affordable products.

Shippinig Optons

Xuanmin offers a variety of shipping options through various carriers. These include major international shipping companies such as CMA CGM, DHL, FedEx, Maersk, APL, OOCL, UPS, TNT, Evergreen Line, MYANG MING and EMS. This means that we are able to efficiently deliver its products to customers around the world, ensuring timely and reliable shipping services.

Partner with Xuanmin for reliable, high-quality milled steel parts that improve the efficiency and performance of your projects. Contact us today to discuss your requirements and get a custom quote.