Products

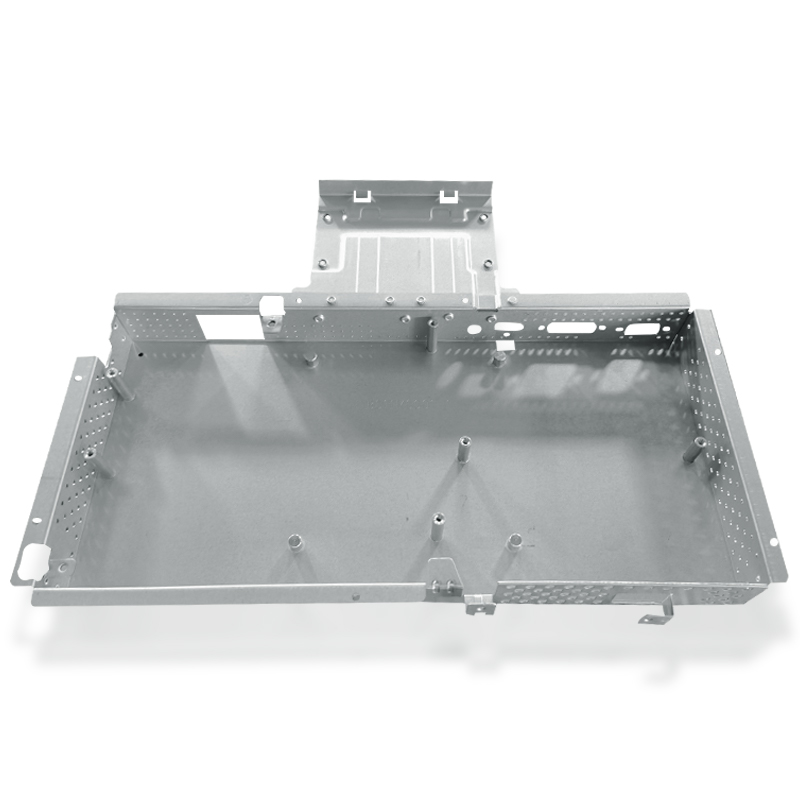

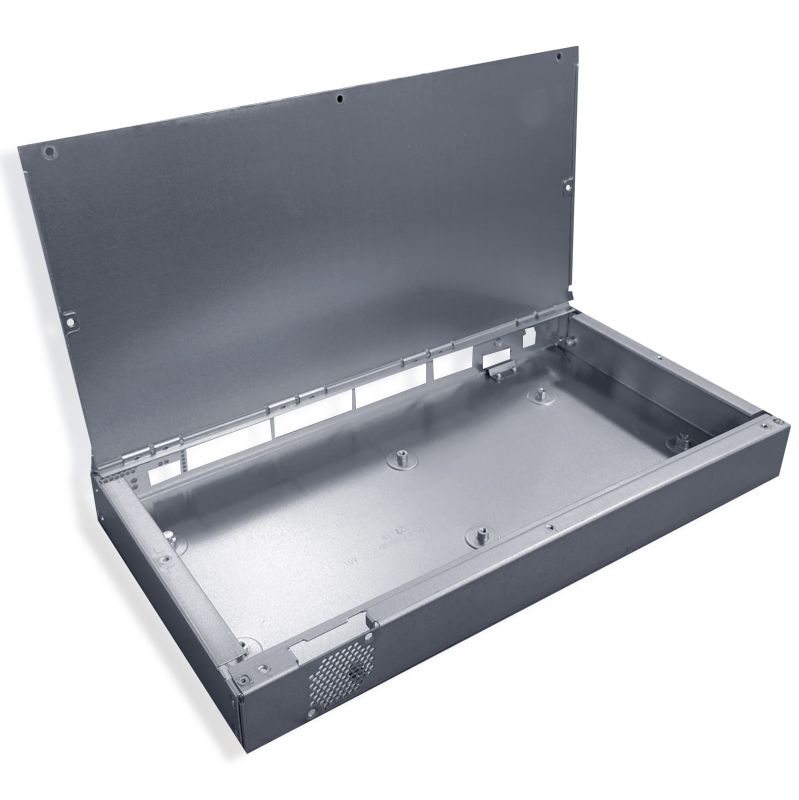

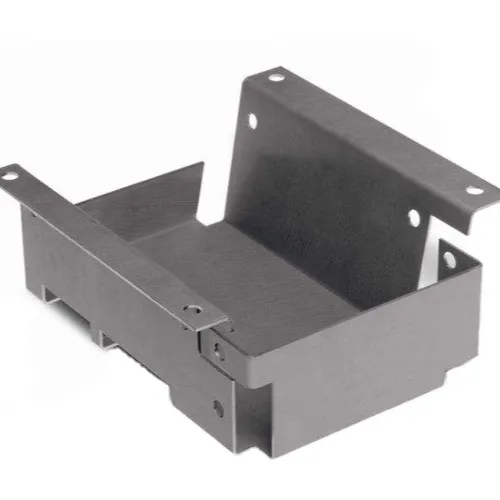

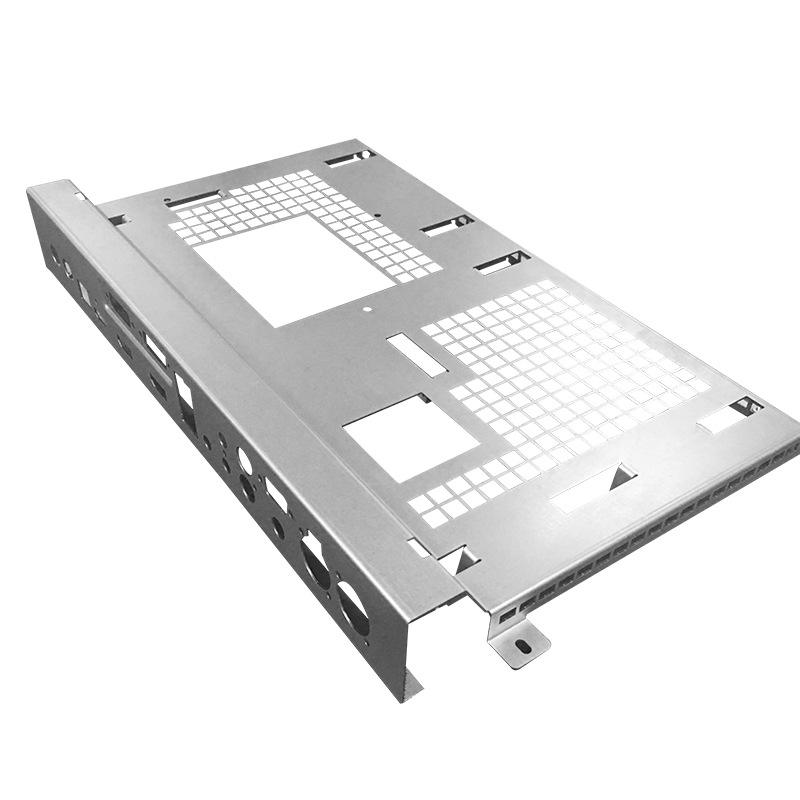

Metal sheet enclosure stamping

Metal sheet enclosure stamping information | |

Name | Leading:Metal enclosure,metal cover,Speaker housing |

Size | Customization

|

Type | Metal enclosure stamping parts ,Shell sheet metal stamping, Galvanized sheet stamping, Custom stamping parts |

Price | Negotiation |

Mold type | Progressive die , continuous die, process die, compound die |

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process

| Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | Metal box,Metal Panel, side plate, Front plate,Top Cover,Rear metal plate,mounting frame, Holder frame, Dam Board , connecting plate, Speaker Grill housing . |

Keywords | Stamping metal box , stamping metal enclosure , Metal machined parts , Stamping parts manufacturing,Precision Metal Stamping parts, Pressed Metal Parts,Metal components stamped,sheet metal box fabrication,metal tray processing ,equipment metal box ,Metal Box Suppliers ,Enclosure Manufacturers,metal box frame,Chassis enclosure Stamping Parts,Computer Metal Stamp Case,Cabinet Chassis Sheet Metal Parts,Stamping equipment case , Equiment metal housing stamping,Sheet metal enclosure bent welding stamping service ,OEM stamping metal parts |

Introduction:

Welcome to our comprehensive guide on customizing metal enclosures, metal covers, and speaker housings. In this guide, we'll explore the various aspects of customization, providing insights into the process, benefits, and key considerations for optimizing these components to suit your specific needs. Whether you're a seasoned manufacturer looking to enhance your product line or an OEM (Original Equipment Manufacturer) seeking bespoke solutions, we've got you covered.

Description:

Metal enclosures, covers, and speaker housings serve critical functions in various industries, providing protection, durability, and aesthetic appeal to electronic devices and equipment. Customizing these components allows businesses, including OEMs, to tailor their designs to meet precise specifications, enhancing functionality, brand identity, and overall product performance.

Customization options for metal enclosures, covers, and speaker housings include:

Material Selection:

Choose from a range of metals such as aluminum, steel, or stainless steel, each offering unique properties in terms of strength, conductivity, and corrosion resistance.

Design Flexibility:

Utilize advanced CAD software and manufacturing techniques to create intricate shapes, sizes, and features that align with your product requirements and branding objectives.

Surface Finishes:

Enhance the visual appeal and durability of metal components with a variety of finishes, including powder coating, anodizing, or electroplating, to achieve desired aesthetics and protection against wear and corrosion.

Custom Cutouts and Features:

Incorporate precise cutouts, holes, and mounting points to accommodate buttons, ports, and connectors, ensuring seamless integration with internal components and external accessories.

Branding and Marking:

Implement custom logos, engravings, or embossments to showcase your brand identity and communicate important product information to users.

Functional Enhancements: Integrate additional features such as ventilation slots, cable