Products

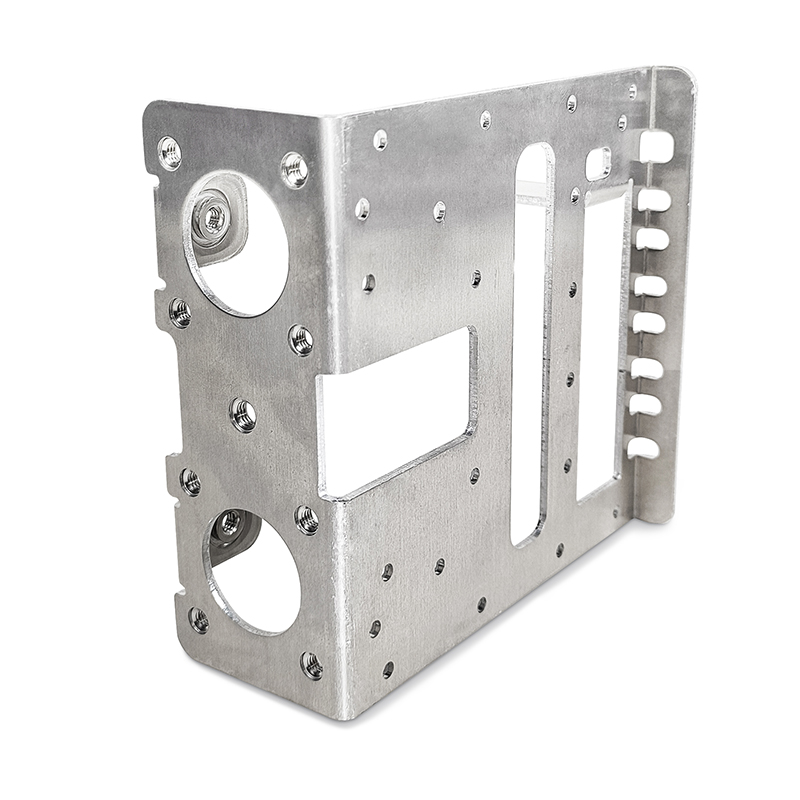

Air conditioning inner steel shell

Air conditioning sheel stamping information | |

Name | Leading:Keyboard stand,shield cover,connector |

Size | Customization |

Type | Communication, electronic hardware stamping parts ,Stainless steel stamping parts ,precision stamping parts |

Price | Negotiation |

Mold type | Progressive die , continuous die, process die, compound die |

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process

| Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | With high precision and high speed stamping ability, it can meet the sheet metal processing of complex electronic products: notebook keyboard bracket, shielding cover, connector, fixed piece, sheet metal shell... |

Key words :

Stamping Refrigerator doors, stamping washing machine covers, TV backplanes manufacturing ,stamping oven parts,electric stamping parts ,home appliances parts

Baking pans mold , Bunpan mold tooling ,cookware sets mold ,bakeware mold die , baking industry,STAMPED METAL BRACKETS,stamping metal hangers,STAMPED ASSEMBLIES,stamped busbars,STAMPED LEAD FRAMES,stamped shielding componets,STAMPED TERMINALS,stamped electrical components .

Household metal stamping parts ,Home Appliances Hardware Stamping Parts ,air conditioner spare parts,

washing machine spare parts,stamping air conditioning appliances

Introduction:

Welcome to our comprehensive guide on customizing Home appliance metal stamping, In this guide, we'll explore the various aspects of customization, providing insights into the process, benefits, and key considerations for optimizing these components to suit your specific needs. Whether you're a seasoned manufacturer looking to enhance your product line or an OEM (Original Equipment Manufacturer) seeking bespoke solutions, we've got you covered.

Description:

Metal stamping parts for home appliances such as the refrigerator doors, washing machine covers, TV backplanes and oven parts, Customers say that our attention to detail, precision, efficiency, and quality are reasons they keep coming back for both residential and commercial appliance metal stamping needs.

PROGRESSIVE DIE HEAVY STAMPING

Our progressive die heavy stamping services utilizing Minster presses provides maximum efficiency and productivity for numerous market segments, due to our highly experienced personnel and state of the art equipment. Our facility includes an in-house toolroom, allowing us to leverage the ability to produce precision progressive dies for production metal stamping. No matter how complex your requirements or the size of your production run, we will provide the utmost in reliable and cost-efficient components.

PROGRESSIVE DIE HIGH SPEED STAMPING

What does it take to achieve the production speed needed to get your parts stamped on schedule and on budget? we uses the very latest in camera vision systems and sensor technology coupled with Bruderer presses to expedite even multimillion-part production runs and ensure 100% quality control.

DIE DESIGN AND MANUFACTURING

Using the highly customized, state-of-the-art Siemens NX 3D CAD modeling software, our team of engineers at designs and produces our dies in house for progressive metal stamping production. This ensures both maximum productivity and cost efficiency for our customers’ projects, especially in the reduction of costs typically associated with changes made in the design phase.

Material Selection:

According to the different auto parts structure and application, choose different metrials such as aluminum, steel, or stainless steel, brass , zinc each offering unique properties in terms of strength, conductivity, and corrosion resistance.

Surface Finishes:

Enhance the visual appeal and durability of metal components with a variety of finishes, including powder coating, anodizing, or electroplating, to achieve desired aesthetics and protection against wear and corrosion.

Quality Control:

Throughout the automotive metal stamping process, quality control measures are in place to ensure that the finished part meets the required specifications. This may involve visual inspections, measurements, and other tests.

Branding and Marking:

Implement custom logos, engravings, or embossments to showcase your brand identity and communicate important product information to users.

Functional Enhancements: Integrate additional features such as ventilation slots, cable