Products

Vehicel chassis metal parts

Vehicel chassis stamping components information | |

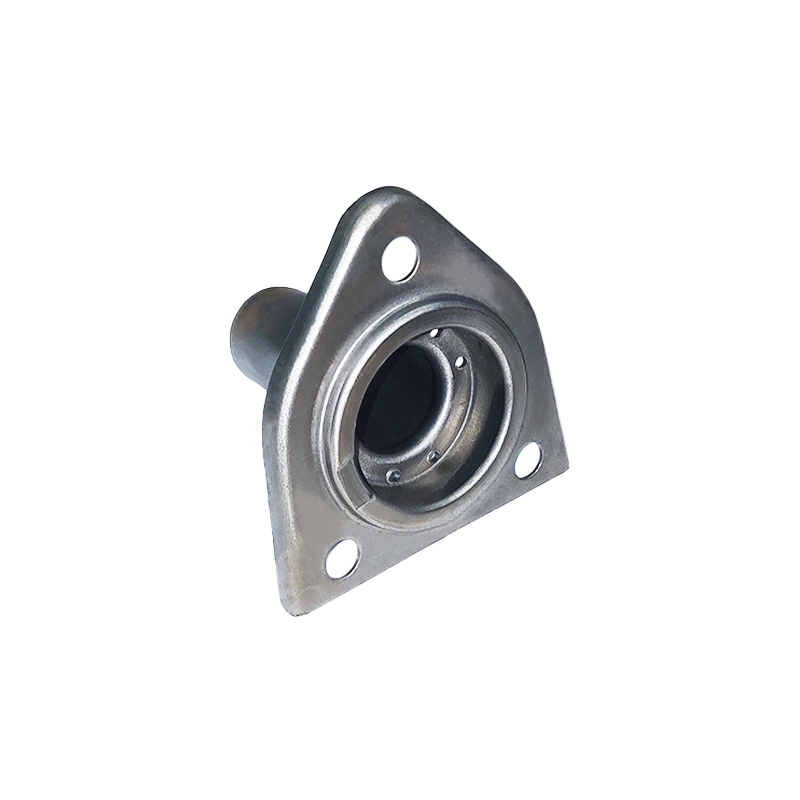

Name | engine metal cover ,stamped engine connectors |

Size | Customization |

Type | Automotive hardware stamping parts, Door trim,panel hinge, limiter ,hardware stamping parts |

Price | Negotiation |

Mold type | Progressive die , continuous die, process die, compound die |

Forming Material | SUS304(Optional:SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet) |

Forming Type | Optional:Punching,bending, drawing, forming, three-dimensional pressing |

Surface treatment | Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process

| Blanking, punching,drawing, forming,cutting, flanging, bending,crimping \ calender \ finishing \ cold extrusion \ punching \ expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | Car stamping parts ,door hinges , bracket , limiter , Reflector, shielding cover, alloy guide, beryllium copper shrapnel ,LED lamp housing , Metal connector, irregular stamping parts , stainless steel shrapnel, Electrical shell , chassis sheet metal ,connectors ,Heat sink , metal cans , gift box , food tray, canteen |

Key words :

Auto stamping parts,Stamping car parts,Vehicle metal parts processing ,Metal Car Parts manufacturing ,Custom car parts fabrication,Custom auto speaker grill,Custom Car Parts processing ,metal car parts stamping ,car custom parts manufacturer,stamping Car parts supplier ,hardware stamping parts,sheet metal parts machining ,Custom Automotive Metal Stamping,Auto Parts Forming,Automotive hardware stamping parts,Car grill housing stamping ,Stamping Speaker Grill,Automotive Stamping metal clips,Auto fasteners stamping ,Metal stamping Clips Suppliers,Automotive Sheet Metal Stamping,Stamping Car chassis metal parts

Introduction:

Welcome to our comprehensive guide on customizing Stamping AUTO PARTS, In this guide, we'll explore the various aspects of customization, providing insights into the process, benefits, and key considerations for optimizing these components to suit your specific needs. Whether you're a seasoned manufacturer looking to enhance your product line or an OEM (Original Equipment Manufacturer) seeking bespoke solutions, we've got you covered.

Description:

Auto stamping parts refers to a manufacturing process that involves shaping and forming sheet metal into specific parts and components used in the production of automobiles. The process typically involves feeding a sheet of metal into a stamping press, which applies pressure and forms the metal into the desired shape using a die or mold. Automotive metal stamping is commonly used to produce parts such as hoods, fenders, doors, and structural components, among others. The process is widely used in the automotive industry due to its cost-effectiveness, efficiency, and ability to produce high volumes of parts with consistent quality.

Design and Tooling

The first step in automotive metal stamping is to design the part or component to be produced. Once the design is finalized, a tool or die is created to shape the metal into the desired form.

Feeding

The metal material is fed into the stamping press. This can be done manually or automatically, depending on the complexity of the part being produced.

Blanking

In this step, the metal material is cut into the appropriate size and shape for the part being produced. This is done using a cutting die that is designed to match the shape of the part.

Forming

The metal material is then shaped into the desired form using a forming die. This can involve a variety of processes such as bending, drawing, and deep drawing.

Piercing

If the part requires holes or other features, a piercing die is used to cut these features into the metal material.

Finishing

Once the metal material has been shaped and pierced, any excess material is trimmed away using a trimming die. This ensures that the part is the correct size and shape.

Assembly

In some cases, multiple stamped parts are assembled together to create a more complex component. This can be done using welding, riveting, or other techniques.

Material Selection:

According to the different auto parts structure and application, choose different metrials such as aluminum, steel, or stainless steel, brass , zinc each offering unique properties in terms of strength, conductivity, and corrosion resistance.

Design Flexibility:

Utilize advanced CAD software and manufacturing techniques to create intricate shapes, sizes, and features that align with your product requirements and branding objectives.

Surface Finishes:

Enhance the visual appeal and durability of metal components with a variety of finishes, including powder coating, anodizing, or electroplating, to achieve desired aesthetics and protection against wear and corrosion.

Quality Control:

Throughout the automotive metal stamping process, quality control measures are in place to ensure that the finished part meets the required specifications. This may involve visual inspections, measurements, and other tests.

Branding and Marking:

Implement custom logos, engravings, or embossments to showcase your brand identity and communicate important product information to users.

Functional Enhancements: Integrate additional features such as ventilation slots, cable