Products

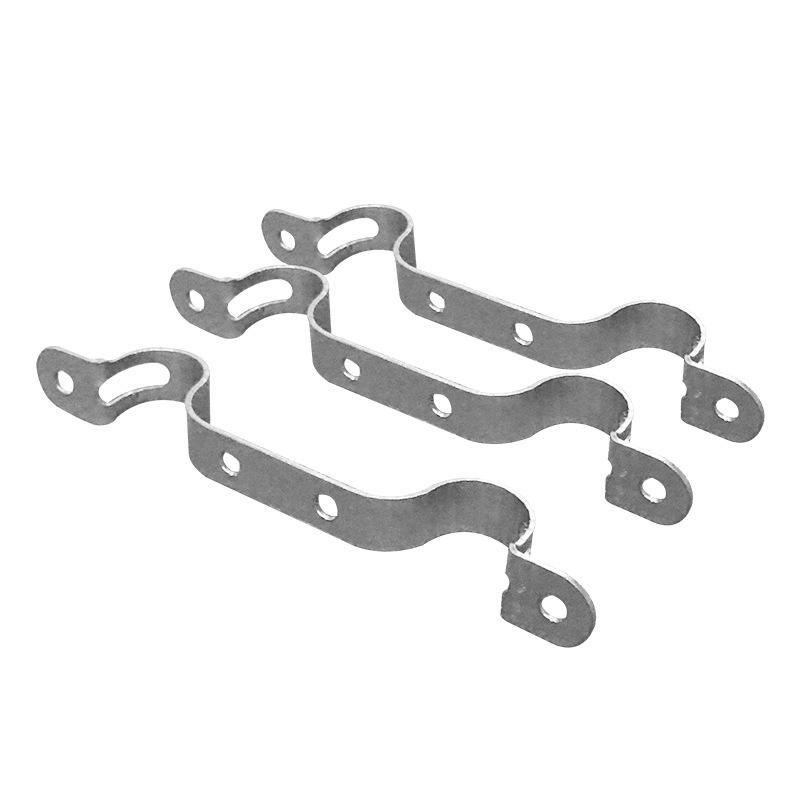

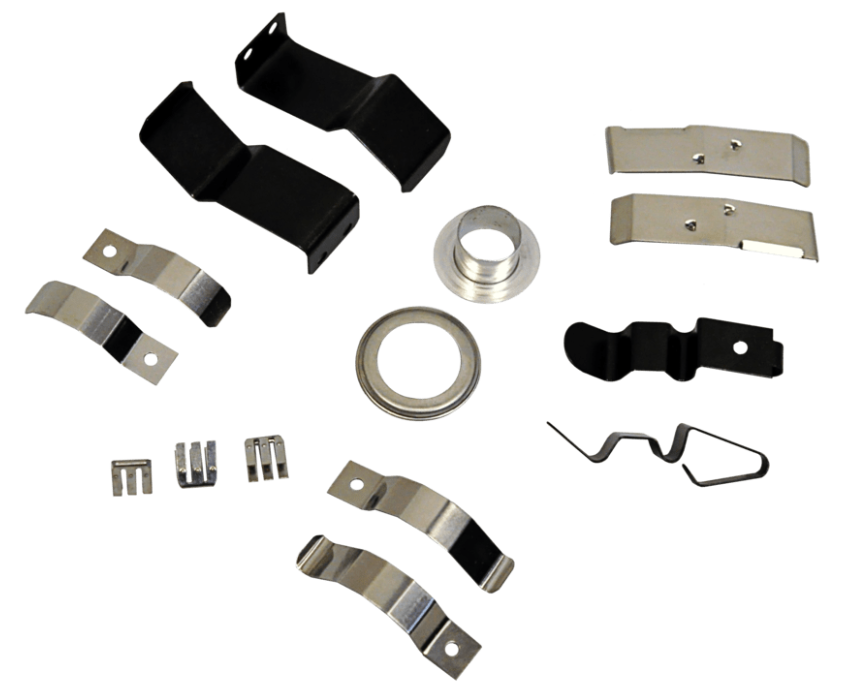

Connector stamping parts

Connector stamping parts information | |

Name | Leading:Shrapnel ,terminal,cTouch plate, conductive piece |

Size | Customization |

Type | Connector insert stamping parts ,Shrapnel stamping parts, Custom stamping parts, Precision stamping parts |

Price | Negotiation |

Mold type | Progressive die , continuous die, process die, compound die |

Xuanmin Tech a manufacturer of sheet metal connectors with an extensive selection of designs, sizes, and thickness.

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process

| Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | Terminal stamping parts, fixed sheet stamping parts, shrapnel stamping parts, Contact sheet stamping parts, conductive sheet stamping parts |

| Key words : | Stamped Electrical Terminals & Connectors,metal forming , connector stamping , stamping metal clips ,metal connector manufacturer , stamping connector pins, automotive connectors , hardware brackets , Connector stamping spring, metal contact parts,terminal block stamping parts ,connector for home appliance, connectors for electrical bicycle ,Alumium connectors , Steel bracket stamping , metal spring stamping,Connector terminal die,custom stamping parts, Stamped Electrical Terminals ,stamped socket,Brass Electrical Connectors,hardware components ,bespoke clips , stamped clips . |

Description:

With the increasing demand for high-precision terminal in the connector market, the stamping process is

paid more and more attention by connector manufacturers.

As the first of the four core processes in manufacturing industry, the technological level of stamping production has

a decisive impact on the quality of finished products.

Why do our connector terminals choose stamping production?

Mainly because the characteristics of stamping process and connector production characteristics match:

(1) stamping is a kind of processing method of high production efficiency, low material consumption, suitable for bulk parts products of the production, easy to realize mechanization and automation, has high production efficiency, at the same time, the stamping production can not only try to less waste, and no waste production, and even in some cases have leftover bits of material, also can make full use of.

(2) The operation process is convenient,Stamping parts generally do not need to be machined, with high dimensional accuracy.

(3)The stamping parts have good interchangeability. Stamping processing stability is good, the same batch of stamping parts, can be exchanged with each other, does not affect the assembly and product performance.

(4)Because the stamping parts are made of sheet metal, its surface quality is good, which provides convenient conditions for subsequent surface treatment processes (such as electroplating and painting).

(5)Stamping processing can obtain high strength, stiffness and light weight parts.

Stamping can produce parts with complex shapes that are difficult to be processed by other metal processing methods.

A Wide Range of Electronics Metal Stamping Applications

Electronics of all kinds require metal components like clips, brackets, frames, contacts, pins, and terminals.

can provide custom-designed metal parts to suit your application requirements.

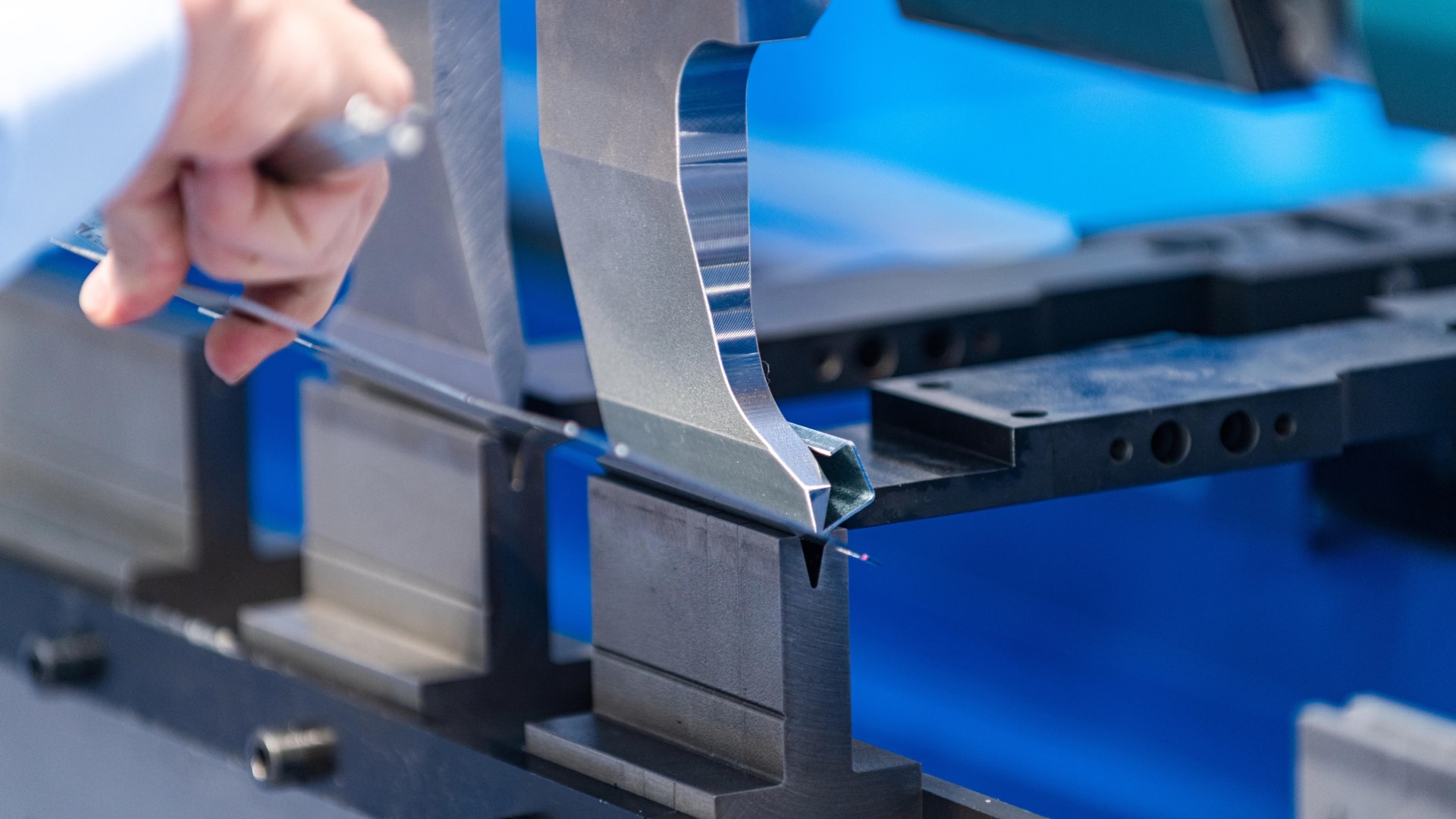

Press Tooling Manufacture

Using the highly customized, state-of-the-art Siemens NX 3D CAD modeling software,

our team of engineers at designs and produces our dies in house for progressive metal stamping production.

This ensures both maximum productivity and cost efficiency for our customers' projects,

especially in the reduction of costs typically associated with changes made in the design phase.

Sheet Metal Materials

Xuanmian uses different sheet metal materials for connectors productions such as:

carbon steel, Aluminum,Zinc

stainless steel, copper, brass, and more.

If you want specific sheet metal materials for the production of your sheet metal parts orders,

we can customize them for you. Send your inquiries!

Metal Surface Treaments:

Enhance the visual appeal and durability of metal components with a variety of finishes,

to achieve desired aesthetics and protection against wear and corrosion.

Metal Peening

Metal Polishing

Metal Burnishing

Metal Phosphatization

Electroplating Metal

Anodizing Metal

Conversion Coatings

Thermal Spraying

Vapor Deposition

Annealing

Related products :

sheet metal junction box ,sheet metal cooling box , hinged sheet metal box ,structure sheet metal box,

sheet metal box with lid , Steel Sheet Auto Clave Box,SheetMetal Enclosure Case,Sheet Metal Tool Box,Precision Small Metal Box