Products

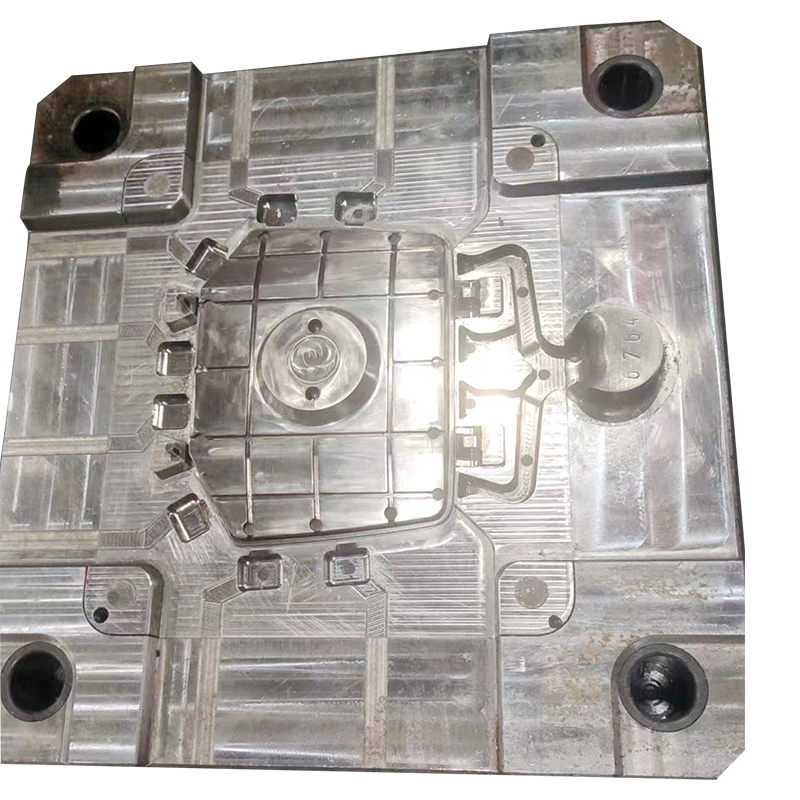

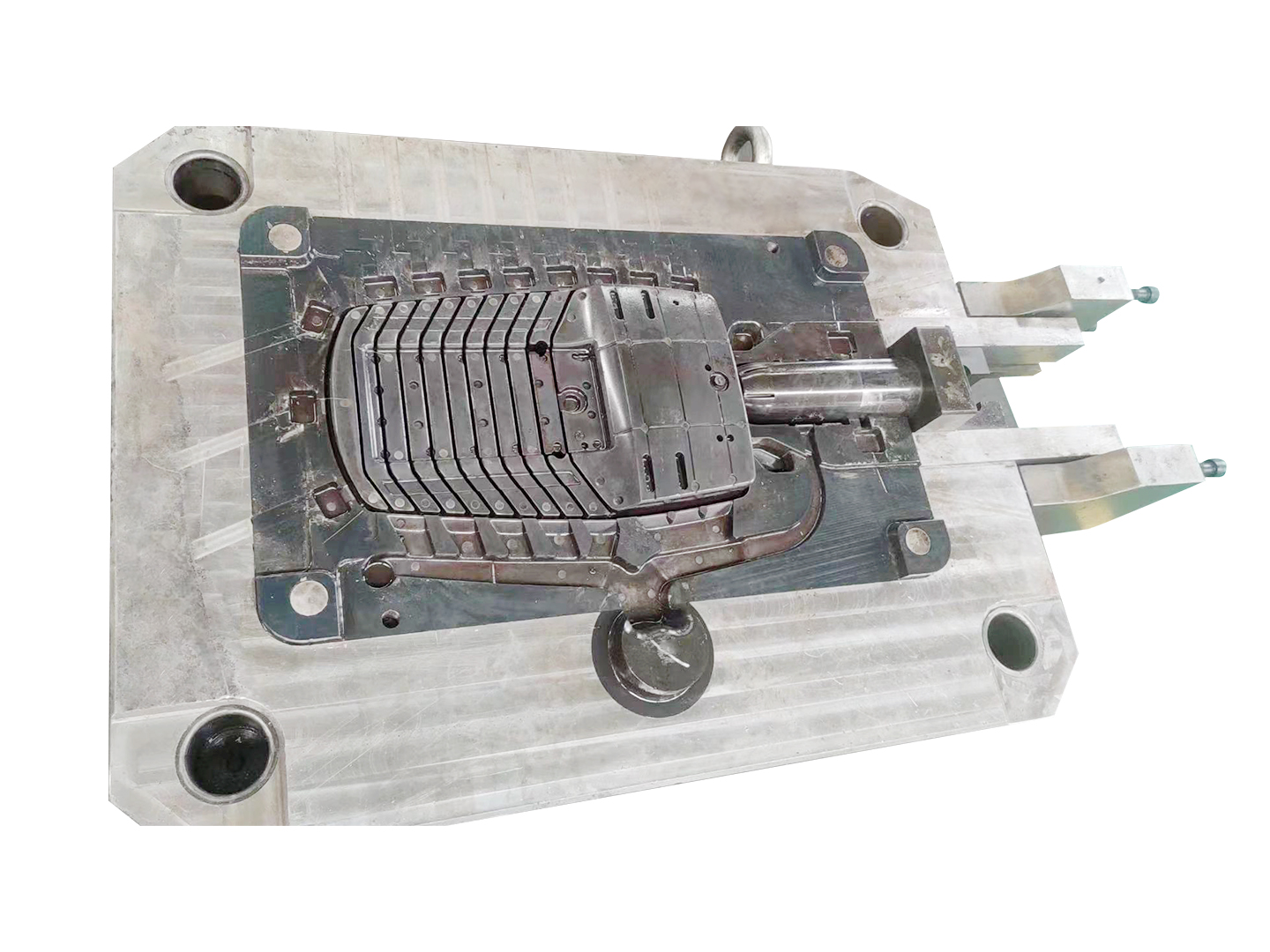

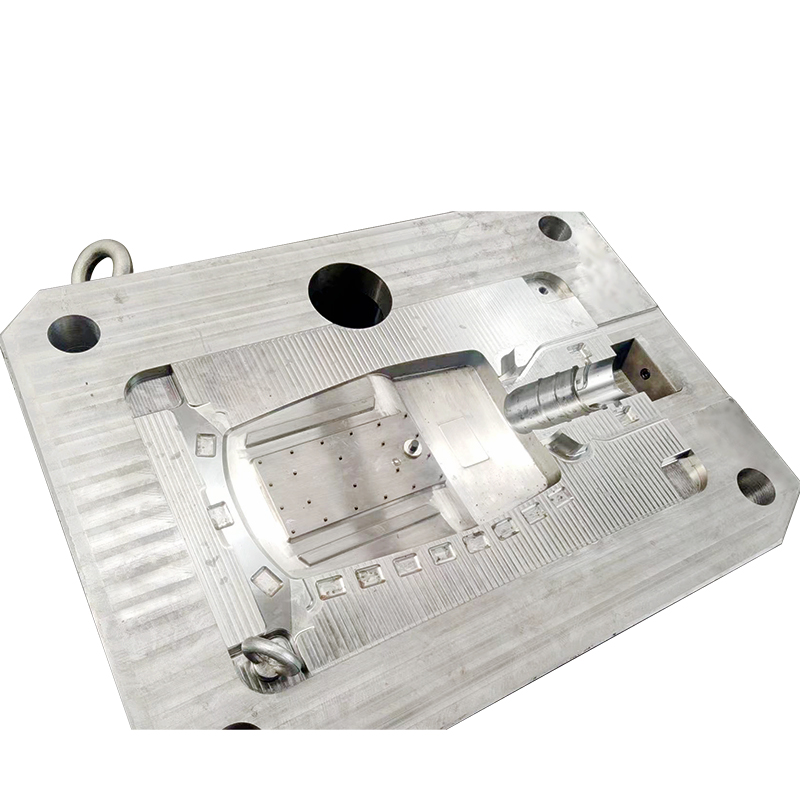

Die casting mold manufacturing

Die casting mold manufacturing and die casting molding service information for LED street light housing | |

Name | Die casting Mold |

Size | Customization |

Mold Type | Die casting die, casting die, metal die |

Production time | 35-40days |

Gating System | Pressure pouring, direct pouring, low pressure pouring |

Mold material

| H13(Optional raw materials:718H、3Cr2Mo、H13H、8Cr3、Cr12...) |

Manufacturing procedure | CNC\EDM\WEDM\Milling Machine\Grinding Machine... |

Surface treatment

| Anodizing (optional processes: electrophoretic coating, spraying and sandblasting, Paintcode and film code . |

Forming processes: | Die casting, drilling, tapping |

Forming Materia | Aluminum alloy (Optional raw materials: aluminum alloy, zinc alloy, magnesium alloy, copper alloy...) |

Capacity | 200,000 pieces per month |

Service | Customized ,product reverse design/mold design/mold manufacturing/die casting molding production complete solution. |

Application | LED lamp housing,, street lamp cover, traditional lamps shell , engine cylinder head, cylinder block, crankcase, decorative parts, handle, electronic housing |

Keywords :

Die casting molds , Die casting tooling , die casting process , die casting housing , die casting cover , die casting parts for lamp .

Die casting manufacturing , Die casting auto parts ,die casting construction parts .

Descriptions:

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process.Die castings are characterized by a very good surface finish (by casting standards) and dimensional consistency.

Cast metal

The main die casting alloys are: zinc, aluminium, magnesium, copper, lead, and tin; although uncommon, ferrous die casting is also possible.[6] Specific die casting alloys include: zinc aluminium; aluminium to, e.g. The Aluminum Association (AA) standards: AA 380, AA 384, AA 386, AA 390; and AZ91D magnesium.

The material used defines the minimum section thickness and minimum draft required for a casting as outlined in the table below. The thickest section should be less than 13 mm (0.5 in), but can be greater.

Metal Minimum section Minimum draft

Aluminium alloys 0.89 mm (0.035 in) 1:100 (0.6°)

Brass and bronze 1.27 mm (0.050 in) 1:80 (0.7°)

Magnesium alloys 1.27 mm (0.050 in) 1:100 (0.6°)

Zinc alloys 0.63 mm (0.025 in) 1:200 (0.3°)

Equipment :

Hot-chamber die casting

Cold-chamber die casting