Products

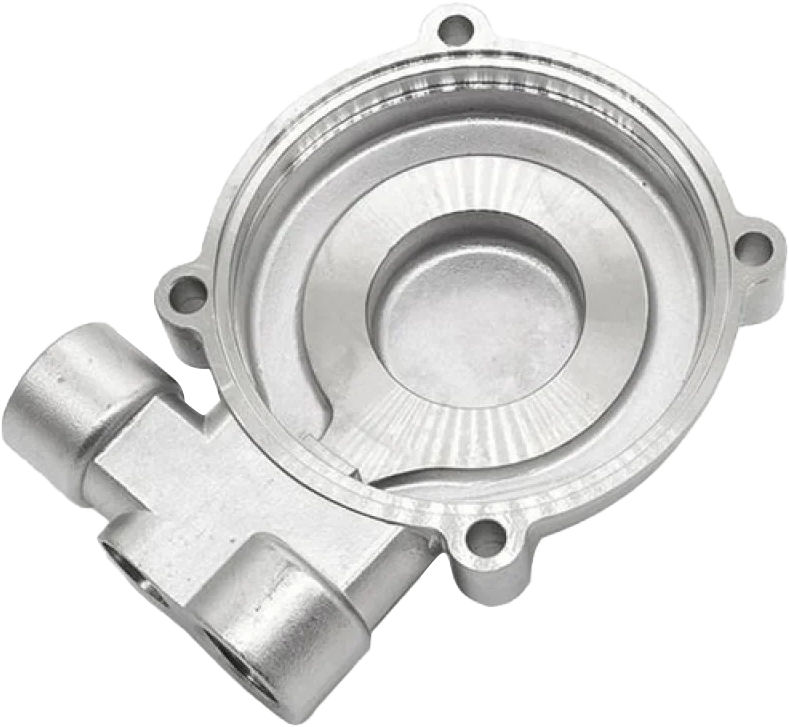

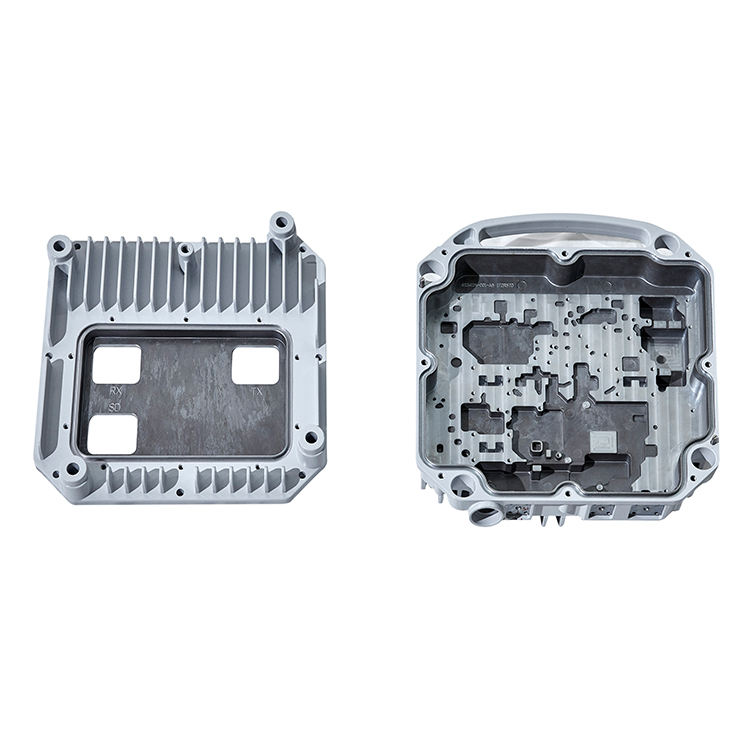

Die cast Bracket metal parts

Bracket die casting parts information | |

Name

| Leading:Bracket,Motor cover,Engine Hood |

Size | Customization |

Type | Aluminum alloy die casting, Zinc alloy die casting ,magnesium alloy die casting ,copper alloy die casting |

Price | Negotiation |

Gating system | Pressure pouring, direct pouring, low pressure pouring |

Forming Material | Optional:Aluminum alloy, zinc alloy, magnesium alloy, copper alloy... |

Forming Type | Support: gravity casting, high pressure casting |

Surface treatment | Optional:Anodizing, electrophoretic coating, spraying and sandblasting, coating and coating |

Forming Process

| H13、718H、3Cr2Mo、H13H、8Cr3、Cr12... |

Forming Thickness | Die casting/precision casting parts |

Capacity | 10 million pieces per month |

Service | Customization ,Product reverse design,mold design,mold manufacturing,die casting molding production ,complete solution |

Appliacation | Motor cover, bracket, crankcase, pump body, valve parts, protective cover... |

Key words :

Aluminum Die Casting Auto Metal Parts,Custom Aluminum Die Casting Process Cookware Chassis Products,Magnesium Die Casting Parts,Aluminum Die Casting,Copper Die Casting,Electrode holders die casting , electrical switchger die casting , electrode plates die casting ,

Die-cast rotors in motors of high efficiency,die -cast Terminal lugs ,Die-cast battery terminals,Contact mechanisms die casting ,die-cast key lock housing,die-cast steering column, Glove box door , die cast radio housing,die cast mirror bracket,clutch brake die casting ,engine block die casting , piston housing die casting ,Lamp heatsink die casting ,die casting lamp housing

Description:

Die casting refers to a process of manufacturing that makes use of high pressure to input a liquid metal into a steel die that is reusable.

The process of rapidly cooling the metal tends to solidify it to form a final shape.

Some of the techniques which you can use in die casting parts include

Hot Chamber Die Casting

Cold Chamber Die Casting

Structural Or High Intensity Die Casting

High vacuum diecasting

Semi-solid die casting

Squeeze die casting

Some of the parts which you can make during diecasting parts process for different industries include:

Automotive industry ,

Builder's Hardware Industry

Telecommunications Industry

Sports Industry

Electrical Machinery Industry And Electrical Appliance Industry

Lighting Industry

some of the benefits of die casting parts include:

-Perfect for rapid and mass production: the die casting parts can be fabricated to form shapes that are complex but accurate.

-Durable, stable, and accurate: die casting parts tend to be very strong and thus possible to sustain injections of high pressure.

-Strong and lightweight: die casting parts even those which have thin walls tend to perform better with counterparts that possess the same dimensions.

-Straightforward assembly: die casting parts tend to produce fastenings which are fundamental thus making the process economical.

DIE DESIGN AND MANUFACTURING

Using the highly customized, state-of-the-art Siemens NX 3D CAD modeling software, our team of engineers at designs and produces our dies in house for progressive metal stamping production. This ensures both maximum productivity and cost efficiency for our customers’ projects, especially in the reduction of costs typically associated with changes made in the design phase.

Material Selection:

According to the different auto parts structure and application, choose different metrials such as aluminum,Magnesium ,Copper , zinc ,Titanium,each offering unique properties in terms of strength, conductivity, and corrosion resistance.

Surface Finishes:

Enhance the visual appeal and durability of metal components with a variety of finishes, including powder coating, anodizing, or electroplating, to achieve desired aesthetics and protection against wear and corrosion.

Quality Control:

Some of the critical points to control quality during the diecasting parts process include:

Dimensional Control

Cosmetic Inspection

Assembly And Function Testing

Branding and Marking:

Implement custom logos, engravings, or embossments to showcase your brand identity and communicate important product information to users.

Functional Enhancements: Integrate additional features such as ventilation slots, cable