Products

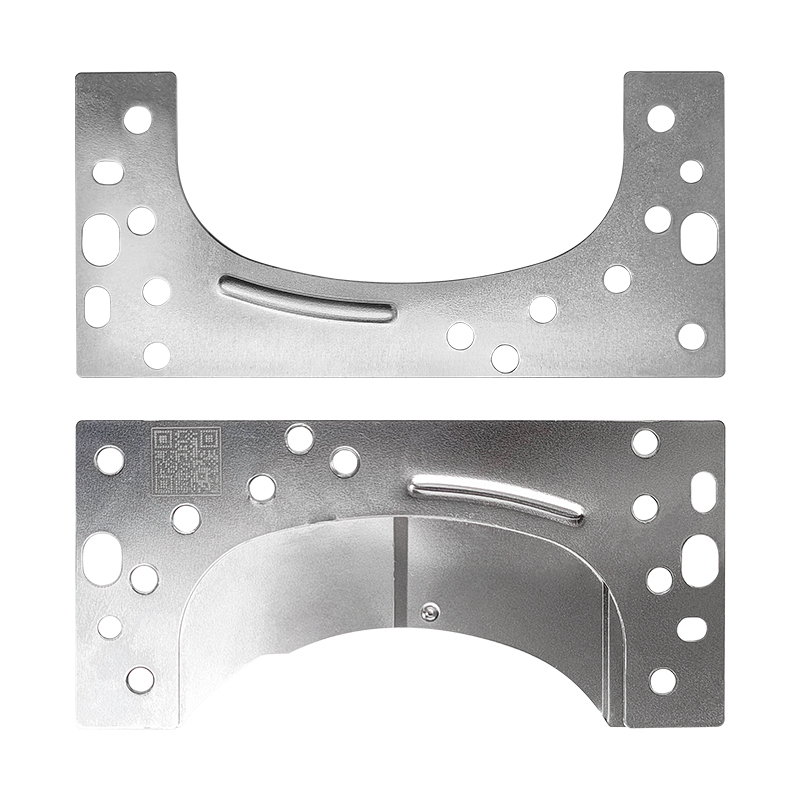

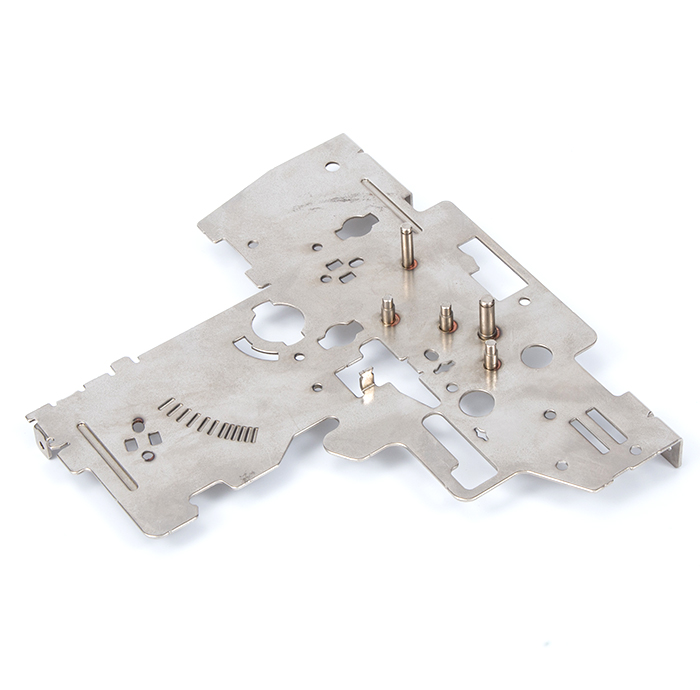

Computer electronics parts stamping

Electronic communication stamping parts information | |

Name | Leading:Keyboard stand,shield cover,connector |

Size | Customization |

Type | Communication, electronic hardware stamping parts ,Stainless steel stamping parts ,precision stamping parts |

Price | Negotiation |

Mold type | Progressive die , continuous die, process die, compound die |

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process

| Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | With high precision and high speed stamping ability, it can meet the sheet metal processing of complex electronic products: notebook keyboard bracket, shielding cover, connector, fixed piece, sheet metal shell... |

Key words :

Metal Stamping for Electronics Parts,electronic computer hardware stamping ,electronic computer parts stamping,Computer Electronics Metal Stamping ,Cameras parts Metal Stamping ,Fitness trackers stamping

Stamping for Handheld augmented reality devices,Heads-up displays metal stamping ,Heating and cooling systems stamping ,Kitchen appliances

Lighting devices,Printers parts stamping ,Power strips stamping ,Robotic vacuums stamping

Smart locks and doorbells stamping ,Smart plugs stamping,Smartphones stamping,Televisions and monitors stamping,Wireless speakers stamping

Description:

Electronics part manufacturers must be able to swiftly produce consistently high-quality components, even in the face of changing demands.

Precise, detailed, and identical parts are vital to the electronics industry, and manufacturers need to stay up-to-date with this dynamic sector to succeed. The advanced techniques of metal stamping mean even the smallest components can be manufactured quickly, precisely, and consistently, even over very large production runs.

Benefits of Metal Stamping for the Electronics Industry

Electronic parts manufacturers employ the metal stamping process to produce the intricate, precise components inherently required by the industry.

Cost-effectiveness

Consistent precision and quality

Versatility

Electronics Metal Stamping Applications

Electronics of all kinds require metal components like clips, brackets, frames, contacts, pins, and terminals. These metal stamping products can be found in:

Computers

Cameras

Fitness trackers

Handheld augmented reality devices

Heads-up displays

Heating and cooling systems

Kitchen appliances

Lighting devices

Printers

Power strips

Robotic vacuums

Smart locks and doorbells

Smart plugs

Smartphones

Televisions and monitors

Wireless speakers

DIE DESIGN AND MANUFACTURING

Using the highly customized, state-of-the-art Siemens NX 3D CAD modeling software, our team of engineers at designs and produces our dies in house for progressive metal stamping production. This ensures both maximum productivity and cost efficiency for our customers’ projects, especially in the reduction of costs typically associated with changes made in the design phase.

Material Selection:

According to the different auto parts structure and application, choose different metrials such as aluminum, steel, or stainless steel, brass , zinc each offering unique properties in terms of strength, conductivity, and corrosion resistance.

Surface Finishes:

Enhance the visual appeal and durability of metal components with a variety of finishes, including powder coating, anodizing, or electroplating, to achieve desired aesthetics and protection against wear and corrosion.

Branding and Marking:

Implement custom logos, engravings, or embossments to showcase your brand identity and communicate important product information to users.

Functional Enhancements: Integrate additional features such as ventilation slots, cable