Products

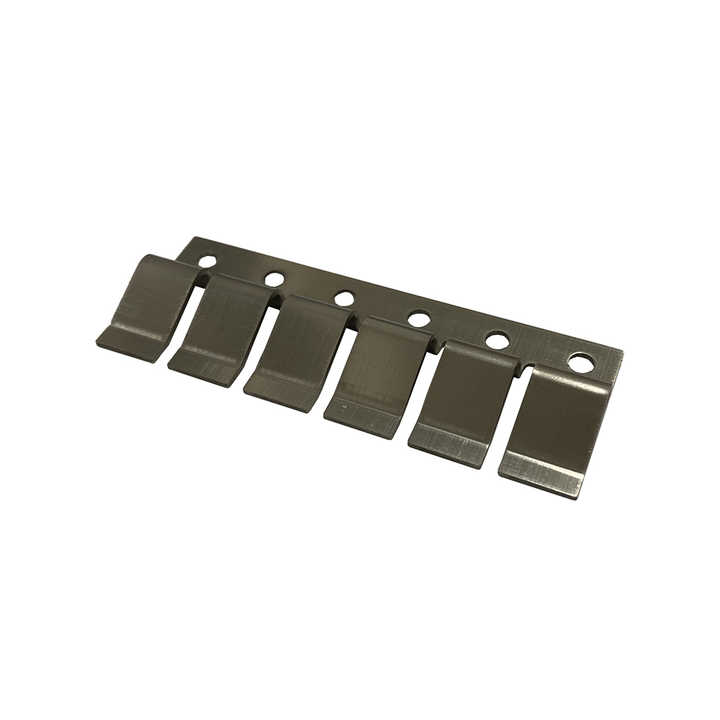

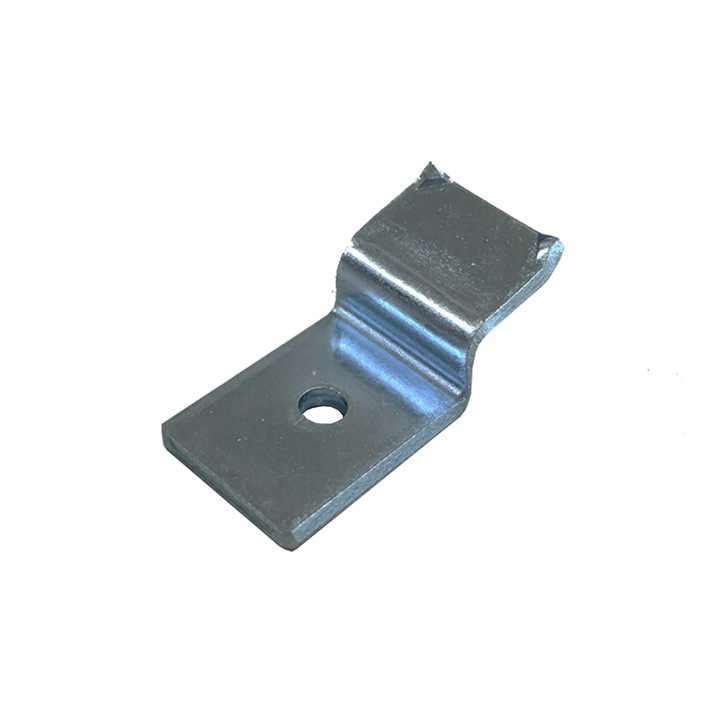

Extruded aluminum heat sink led light heat sink

Extruded aluminum heat sink information | |

Name | Radiator/Aluminum Extrusion Stamping/Metal Radiator Customization |

Size | Customization |

Type | Electronic parts sheet metal bending and stamping technology |

Price | Negotiation |

Mold type | Progressive die, continuous die, process die, compound die |

Forming Material | SUS304、SGCC、SECC、SPTE、Aluminum Sheet、Copper Sheet |

Forming Type | Punching,bending, drawing, forming, three-dimensional |

Surface treatment | Support :Polishing,dusting,spraying,electroplating,video game,anodizing |

Forming Process | Support:Blanking, punching,drawing,forming, cutting,flanging,bending, crimping,calender,finishing,cold extrusion, punching,expansion type |

Forming Thickness | Support:0.0157"~0.7874"(0.4mm~20mm) |

Capacity | 10 million pieces per month |

Service | Support Customization , Provide Mold design , Manufacturing ,A complete one-stop solution for stamping production |

Application | Terminal stamping parts, fixed sheet stamping parts, shrapnel stamping parts, Contact sheet stamping parts, conductive sheet stamping parts |

Hot Keywords

Aluminum stamping, aluminum radiator, radiator stamping, radiator stamping parts, metal bending, bending stamping parts, metal motor parts, hardware sheet metal, electronic parts, electronic stamping parts, communication parts processing, sheet metal processing, sheet metal bending, stamping technology, OEM sheet metal, camera stamping, computer stamping, mold stamping, stamping processing

Description of electronic stamping parts

Electronic stamping parts refer to metal parts used in various electronic devices, which are usually produced by precision stamping process with high precision and consistency. They are widely used in the manufacture of electrical and electronic products to provide structural support, electrical connection, heat conduction, shielding and other functions. The materials of electronic stamping parts are mostly conductive or corrosion-resistant metals such as copper, stainless steel and aluminum to ensure the durability and stability of electronic equipment.

Features of electronic stamping parts

High precision

Electronic equipment has extremely high requirements for size and shape accuracy. Stamping parts are formed by precision stamping to ensure that each part has consistent size and shape for easy assembly.

High conductivity

Electronic stamping parts usually use conductive materials, which are suitable for conductive parts such as connectors and connectors to ensure stable current transmission.

High strength and durability

Electronic stamping parts require sufficient strength to withstand the stress and frequent connection and disassembly during equipment operation.

Lightweight and corrosion resistance

In electronic equipment, especially portable equipment, lightweight and corrosion resistance are very important to extend product life and meet portability needs.

The role of aluminum extrusion stamping parts

Structural support and lightweight

Aluminum extrusion stamping parts are often used in products that require lightweight structures, such as automobiles, aerospace, and electronic products. Due to the lightweight characteristics of aluminum, extrusion stamping parts can not only provide a strong support structure, but also reduce the weight of the product, improve energy efficiency and performance.

Excellent thermal conductivity

Aluminum itself has good thermal conductivity. Aluminum extrusion stamping parts are often used in electronic equipment, LED heat sinks, computer components and other occasions that require efficient heat dissipation, which helps to improve product stability and extend equipment life.

Corrosion resistance and durability

Aluminum is naturally corrosion-resistant and suitable for outdoor or humid environments, especially in household appliances, building materials and automotive accessories. Aluminum parts made by stamping and extrusion processes are not only durable, but also can adapt to various harsh conditions.

Aesthetics and ease of processing

Aluminum extrusion stamping parts have high flexibility in shape design and subsequent surface treatment. They can be easily processed into complex shapes, and the surface can be anodized, electroplated and other treatments to enhance the appearance, making them suitable for products that require beautiful designs such as consumer electronics.

Environmental protection and recyclability

Aluminum is easy to recycle and reuse, which reduces resource waste and reduces the impact of production on the environment. Therefore, aluminum extrusion stamping parts meet the needs of sustainable development and are suitable for industries with strict environmental protection requirements.

Main Application Areas

Motor stampings are widely used in multiple industries to support the production and operation of various types of motors.

Automotive industry: Motor stampings are widely used in various types of motors in automobiles, such as drive motors for electric vehicles, fan motors for fuel vehicles, seat adjustment motors, and window lift motors. These motors require high efficiency and durability, and stampings help achieve lightweight and efficient heat dissipation.

Home appliance industry: Motor equipment in home appliances, such as air conditioners, washing machines, refrigerators, and vacuum cleaners, rely on stampings to keep the motors working stably while reducing energy consumption and noise.

Industrial automation: In industrial equipment, motor stampings are used for drive motors, stepper motors, and servo motors, etc., and are used in automation equipment, robots, and other occasions, requiring high precision, low energy consumption, and long life.

Wind power generation: The motors of large wind turbines also use iron cores made of stampings to improve power generation efficiency and motor performance, and meet the requirements of high stability and durability.

Consumer electronics: In smartphones, watches, and other portable devices, motor stampings are used to make small motor components such as vibration motors to meet the product's needs for lightweight, precision, and low noise.

Aerospace: Precision motors in aerospace are also manufactured using stamping parts to ensure the stability and reliability of motor components under high stress and complex environments.

Tool Design and Manufacturing

Our team of engineers designs and produces tooling for progressive metal stamping production in-house, using highly customized, state-of-the-art Siemens NX 3D CAD modeling software. This ensures maximum productivity and cost efficiency for our customers’ projects, especially reducing costs typically associated with changes during the design phase.

Processing Process

Xuanmin has a strict process for producing high-quality molds, CNC machined parts and samples. The process involves several key stages, including programming, raw material selection, CNC machining, quality inspection, surface treatment, retesting, packaging and shipping. This multi-step approach ensures that the products meet strict quality standards throughout the production process. The company also emphasizes quality control from IQC to OQC, further demonstrating their commitment to producing reliable and affordable products.

Shippinig Optons

Xuanmin offers a variety of shipping options through various carriers. These include major international shipping companies such as CMA CGM, DHL, FedEx, Maersk, APL, OOCL, UPS, TNT, Evergreen Line, MYANG MING and EMS. This means that we are able to efficiently deliver its products to customers around the world, ensuring timely and reliable shipping services.

Partner with Xuanmin for reliable, high-quality milled steel parts that improve the efficiency and performance of your projects. Contact us today to discuss your requirements and get a custom quote.