Products

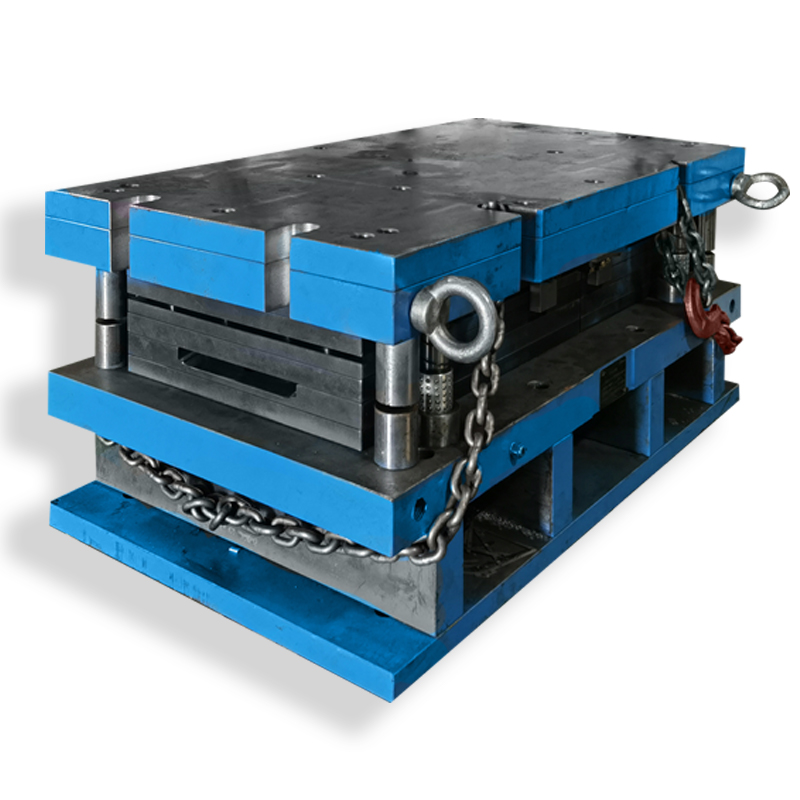

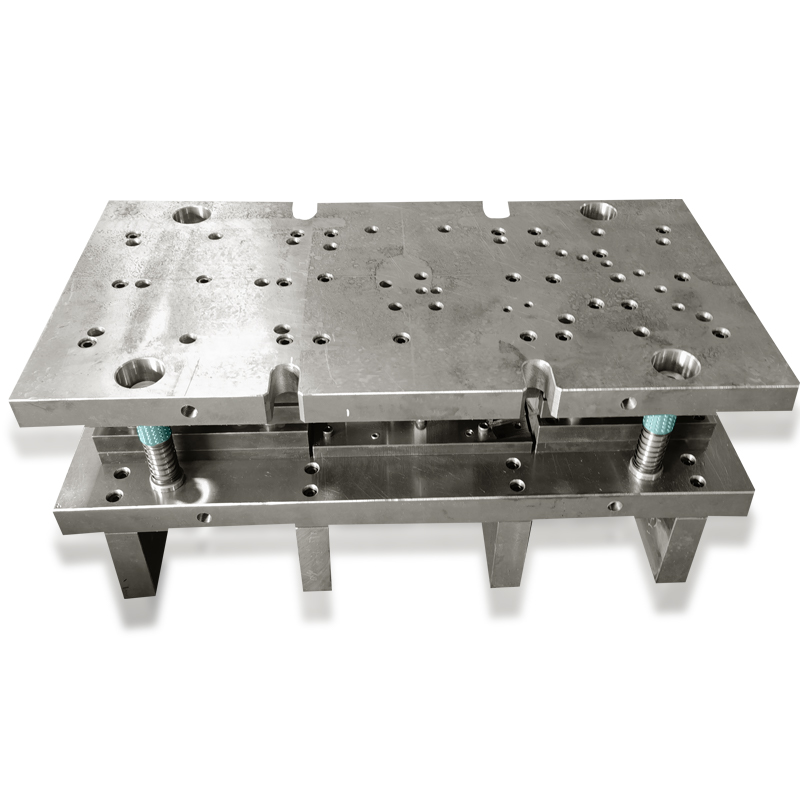

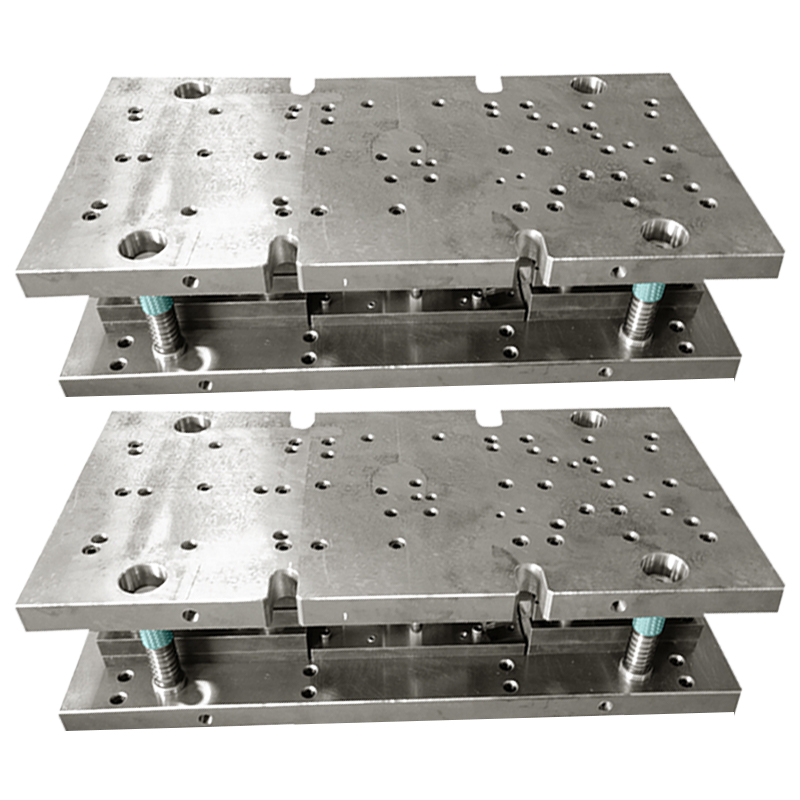

Stamping mold for electirc metal parts

Stamping mold for electirc metal parts information | |

Name | Stamping Die,stamping tooling , Mold die , |

Size | Customization |

Mold Type | Stamping die, sheet metal stamping die, metal stamping die |

Production time | 30 - 45days |

Combination type | Single process die ,compound die , progressive die |

Mold Materials | Cr12MoV、D2、DC53、SKD11、Cr4W2MoV、Cr5Mo1V、Cr6WV、S7... |

Manufacturing procedure | CNC\EDM\WEDM\Milling Machine\Grinding Machine... |

Forming Type | Blanking die, bending die, drawing die, forming die, three-dimensional pressing die |

Forming Process | Flanging, punching, bending,necking ,triming,cutting , forming,calender, drawing, finishing cold extrusion \ blanking \ expansion process |

Forming Material | Zinc-dipped steel SGCC, galvanized steel SECC, stainless steel SUS, tinned steel SPTE, aluminum/copper alloy plate, spring steel |

Capacity | Ten million pieces per month |

Service | Support Customization, Mold design, mold manufacturing, stamping production and complete one-stop solutions.。 |

Application | Car stamping parts ,door hinges , bracket , limiter , Reflector, shielding cover, alloy guide, beryllium copper shrapnel ,LED lamp housing , Metal connector, irregular stamping parts , stainless steel shrapnel, Electrical shell , chassis sheet metal ,connectors ,Heat sink , metal cans , gift box , food tray, canteen |