Products

Turning and milling composite parts

Turning and milling composite parts Information | |

Name | CNC milling/turning parts/anodizing/Composite parts |

Size | Customization |

Type | CNC machining , precision machining ,milling , turning,wire cutting, EDM machining |

Price | Negotiation |

Mold type | Support: Metal, bakelite, plastic, wood |

Machining material | Steel stainless :SUS304,303,316,420,440c,630,etc, Carbon steel(#45,A3,etc), Aluminum(6061,6063,7075,etc.), Copper(Brass, copper, bronze, phosphor bronze, etc), Iron(1214,1215 etc), Titanium alloy, iron-nickel alloy, PEEK, POM, PE, PET and other materials |

Machining scope | Diameter:0.1-200mm、Length:0.5mm-1000mm |

Tolerance | +/-0.003mm |

Surface color | Natural color, passivation, white zinc, black zinc, blue zinc, nickel, chromium, aluminum oxidation of various colors |

MOQ | 1000PCS |

Serivce | Processing according to Samples, materials, drawings...etc. |

Application | Shaft parts, disc sleeve parts, box parts, molds and fixtures, complex curved parts, hole and thread parts, special-shaped non-standard parts, custom parts... |

Keywords:

Precision CNC Milled Parts, Milled Parts Supplier, Custom CNC Prototypes, CNC Milling, Machined Components, Custom CNC Components, Custom Stainless Steel Parts, CNC Turned Parts, Machining Manufacturers, Automotive CNC Machined Parts, CNC Parts, CNC Machining Services, CNC Parts Products, Mill-Turn Parts

Description:

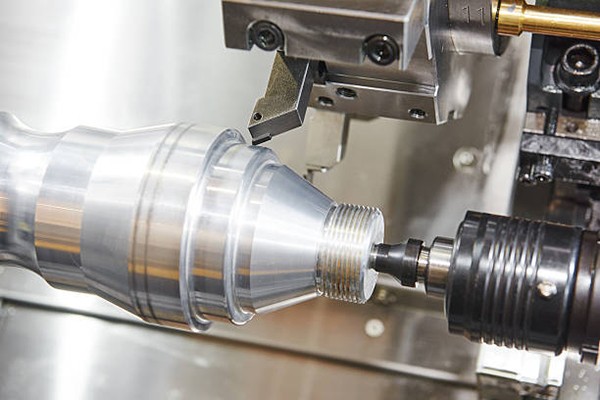

Milling-turning parts are manufactured by combining turning and milling processes. This method can complete multiple processing steps on one device, thereby improving production efficiency and reducing processing time. Milling-turning parts usually have complex geometric shapes and high-precision processing requirements, and are suitable for the production of parts such as shafts, housings and cylindrical components that require precise dimensions and surface quality. Zhiheng Hardware Co., Ltd. is committed to providing high-quality milling-turning parts for the CNC machining industry to meet the diverse needs of customers in various application scenarios.

Advantages of milling-turning:

Improve processing efficiency: Multiple processes can be completed in one clamping, which reduces the time for transporting and clamping workpieces between different machine tools, not only greatly shortening the production cycle, but also minimizing the possibility of human error.

High processing accuracy: Since milling-turning can complete multiple processes on the same machine tool, the positioning accuracy of the workpiece is greatly improved. This is especially beneficial when processing complex parts, because milling-turning technology can ensure high-precision alignment of each processing surface and avoid errors caused by repeated positioning.

Complex shape processing: Milling-turning is suitable for processing parts with complex shapes and multiple surfaces. Through program control, the machine tool can flexibly switch between turning and milling processes, easily meeting various irregular surfaces, bevels, spiral grooves and other processing requirements.

Reducing costs: By reducing the transfer of workpieces between different processes, milling-turning can effectively reduce production costs. Coupled with the reduction in processing time and the improvement in accuracy, companies can produce higher quality products with less resources and time.

Application fields of turn-mill composite parts:

Turn-mill composite parts are widely used in high-precision manufacturing fields such as aerospace, automobile manufacturing, medical equipment, and electronic communications.

For example, in the aerospace industry, engine parts are often complex in shape and hard in material, and traditional processing technology is difficult to efficiently achieve the required precision. Turn-mill composite technology can not only process complex three-dimensional surfaces, but also ensure the stability and reliability of parts under high temperature and high pressure conditions.

In the field of automobile manufacturing, mill-turn composite parts are widely used in the processing of key parts such as engines, gearboxes, and chassis. These parts have extremely high requirements for dimensional accuracy and surface finish, and even a slight deviation will affect the performance of the entire vehicle.

Processing Process:

Xuanmin has a strict process for producing high-quality molds, CNC machined parts and samples. The process involves several key stages, including programming, raw material selection, CNC machining, quality inspection, surface treatment, retesting, packaging and shipping. This multi-step approach ensures that the products meet strict quality standards throughout the production process. The company also emphasizes quality control from IQC to OQC, further demonstrating their commitment to producing reliable and affordable products.

Shippinig Optons:

Xuanmin offers a variety of shipping options through various carriers. These include major international shipping companies such as CMA CGM, DHL, FedEx, Maersk, APL, OOCL, UPS, TNT, Evergreen Line, MYANG MING and EMS. This means that we are able to efficiently deliver its products to customers around the world, ensuring timely and reliable shipping services.

Partner with Xuanmin for reliable, high-quality milled steel parts that improve the efficiency and performance of your projects. Contact us today to discuss your requirements and get a custom quote.