Products

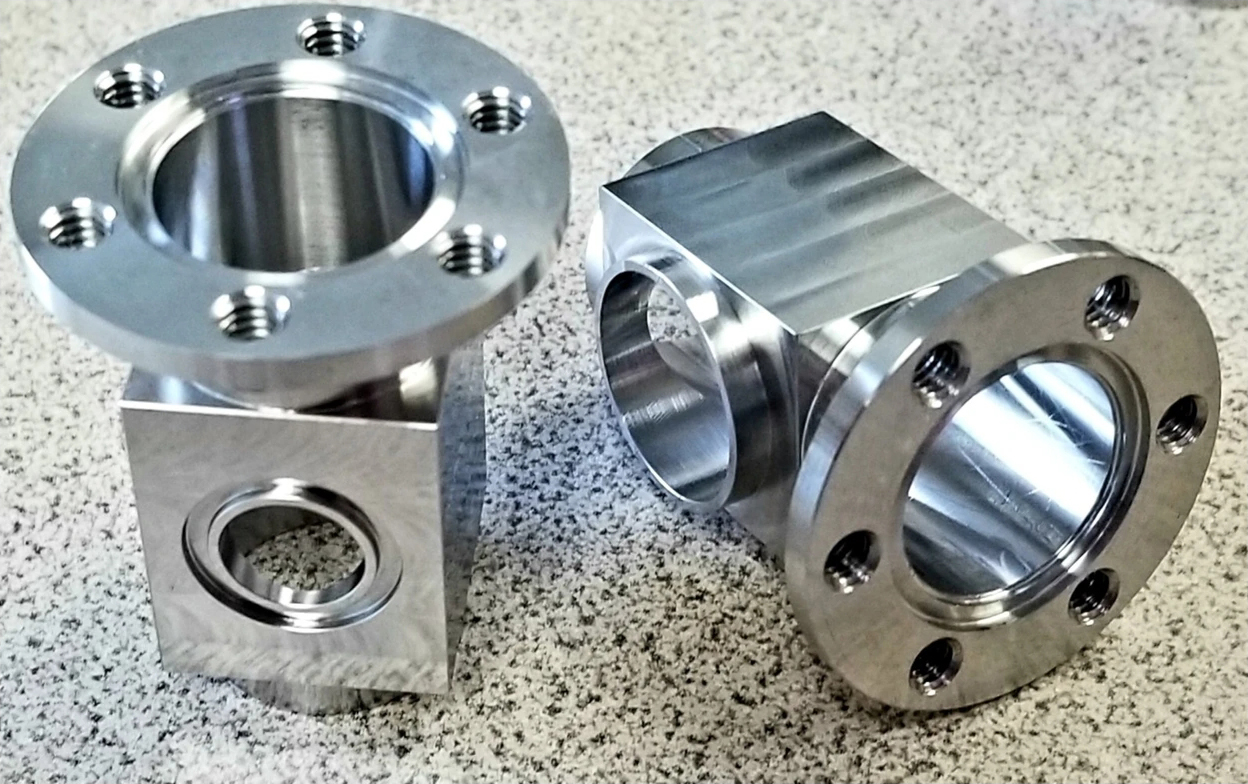

CNC Milling steel parts

CNC Milling steel parts Information | |

Name | CNC milling/turning parts/anodizing/Milling steel |

Size | Customization |

Type | CNC machining , precision machining ,milling , turning,wire cutting, EDM machining |

Price | Negotiation |

Mold type | Support: Metal, bakelite, plastic, wood |

Machining material | Steel stainless :SUS304,303,316,420,440c,630,etc, Carbon steel(#45,A3,etc), Aluminum(6061,6063,7075,etc.), Copper(Brass, copper, bronze, phosphor bronze, etc), Iron(1214,1215 etc), Titanium alloy, iron-nickel alloy, PEEK, POM, PE, PET and other materials |

Machining scope | Diameter:0.1-200mm、Length:0.5mm-1000mm |

Tolerance | +/-0.003mm |

Surface color | Natural color, passivation, white zinc, black zinc, blue zinc, nickel, chromium, aluminum oxidation of various colors |

MOQ | 1000PCS |

Serivce | Processing according to Samples, materials, drawings...etc. |

Application | Shaft parts, disc sleeve parts, box parts, molds and fixtures, complex curved parts, hole and thread parts, special-shaped non-standard parts, custom parts... |

Keywords:

Precision CNC Milled Parts, Milled Parts Supplier, Custom Cnc Prototypes, CNC Milling, Machining Components, Custom Cnc Components, Custom Stainless Steel Parts, CNC Turned Parts, Machining Manufacturer, Automotive CNC Machining Parts, CNC Parts,CNC Milled Aluminum,Milling copper,CNC machining services, CNC parts products,Milling steel parts

Description:

Copper is a popular choice for numerous applications due to its excellent thermal and electrical conductivity, but machining copper requires precision and expertise. We ensure that each copper part is manufactured to exact specifications with an excellent finish and accuracy. We utilize a range of cutting-edge tools and techniques to address the unique challenges of copper milling, including maintaining optimal cutting speeds and tool wear management.

Advantages of CNC machining:

Rapidly remove large amounts of metal material

Highly accurate, fast and repeatable

Applicable to many different types of substrates

Scalable in quantities from 1 to 100,000

Low tooling and preparation costs

Economical

Fast turnaround

CNC machining applications:

Rapid tooling (jigs or molds)

Rapid prototyping

End-use production

Industries Served by CNC Machining:

Aerospace | Agriculture | Automotive | Construction

Dental | Electronics | Firearms | Hospitality | Manufacturing

Metalworking | Military | Production | Publishing | Transportation

Processing Process:

Xuanmin has a strict process for producing high-quality molds, CNC machined parts and samples. The process involves several key stages, including programming, raw material selection, CNC machining, quality inspection, surface treatment, retesting, packaging and shipping. This multi-step approach ensures that the products meet strict quality standards throughout the production process. The company also emphasizes quality control from IQC to OQC, further demonstrating their commitment to producing reliable and affordable products.

Shippinig Optons:

Xuanmin offers a variety of shipping options through various carriers. These include major international shipping companies such as CMA CGM, DHL, FedEx, Maersk, APL, OOCL, UPS, TNT, Evergreen Line, MYANG MING and EMS. This means that we are able to efficiently deliver its products to customers around the world, ensuring timely and reliable shipping services.

Partner with Xuanmin for reliable, high-quality milled steel parts that improve the efficiency and performance of your projects. Contact us today to discuss your requirements and get a custom quote.