Products

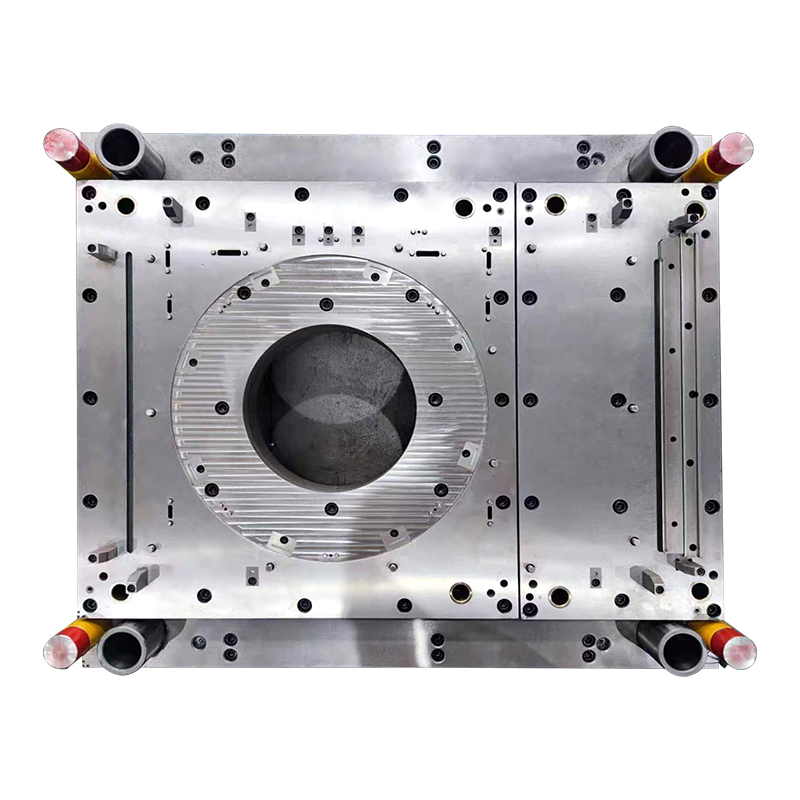

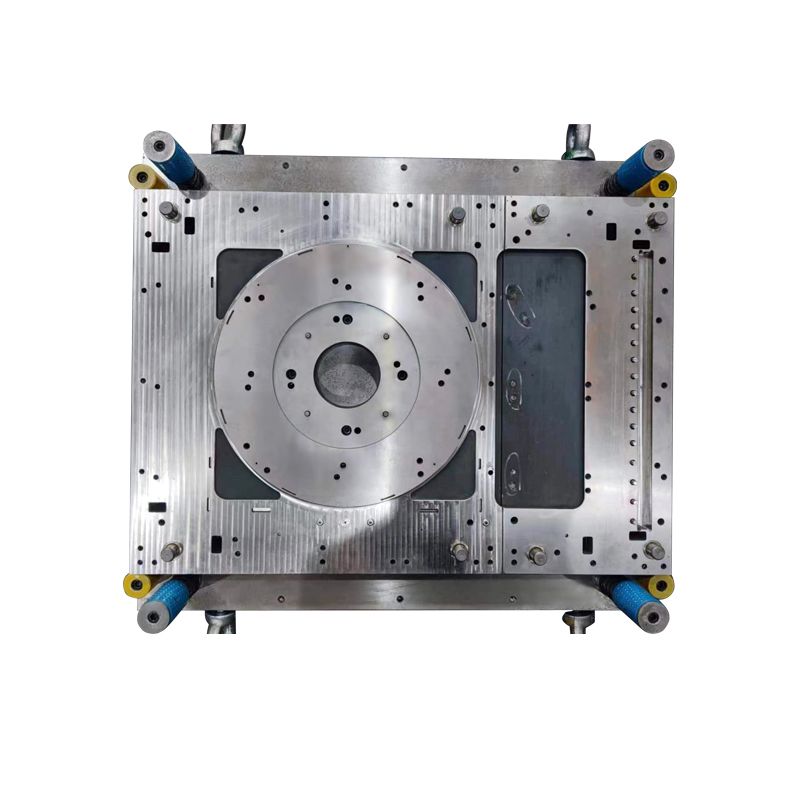

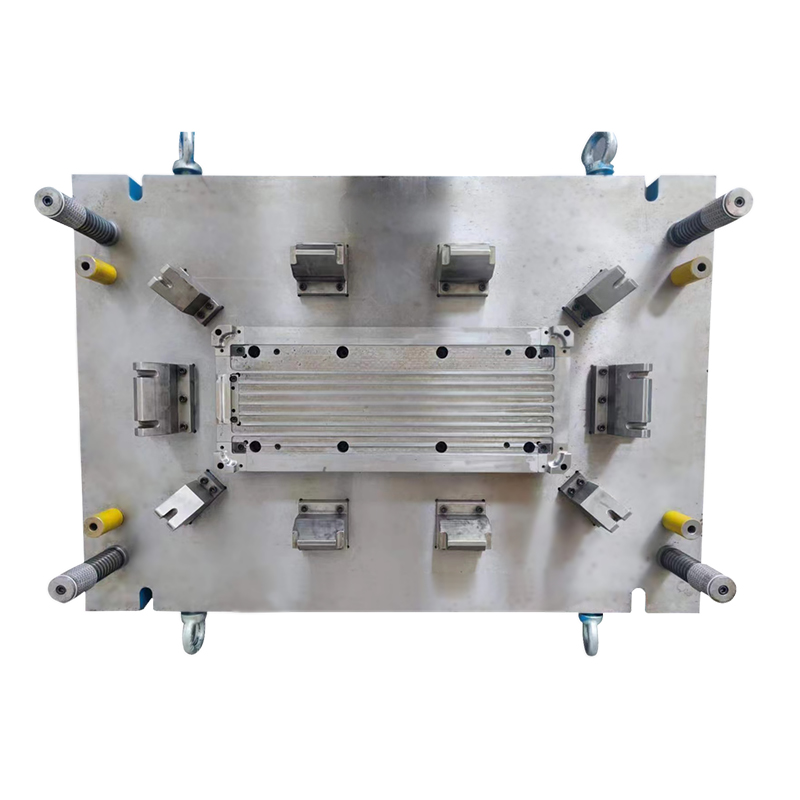

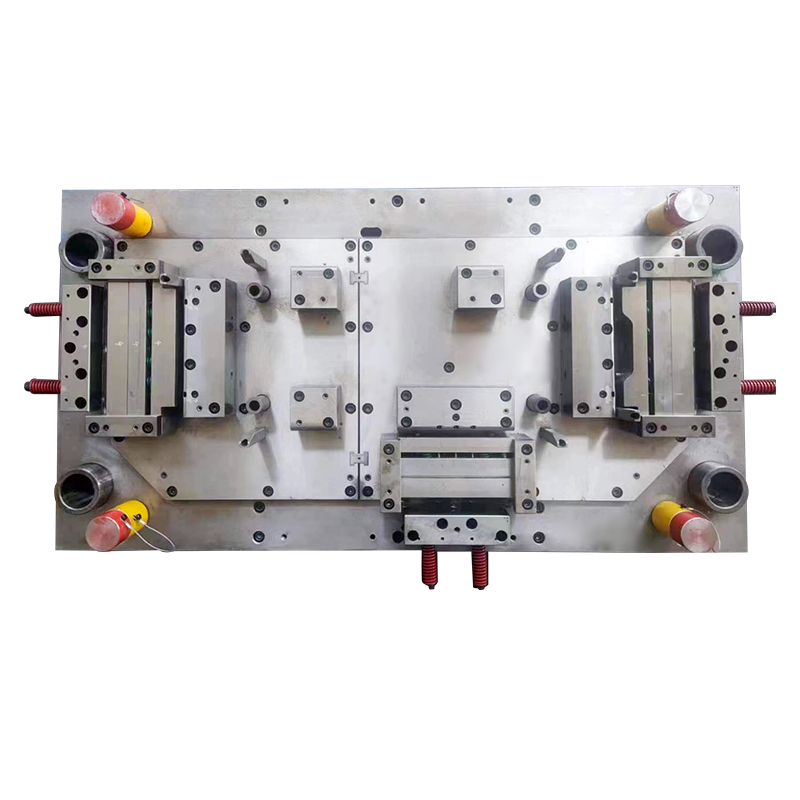

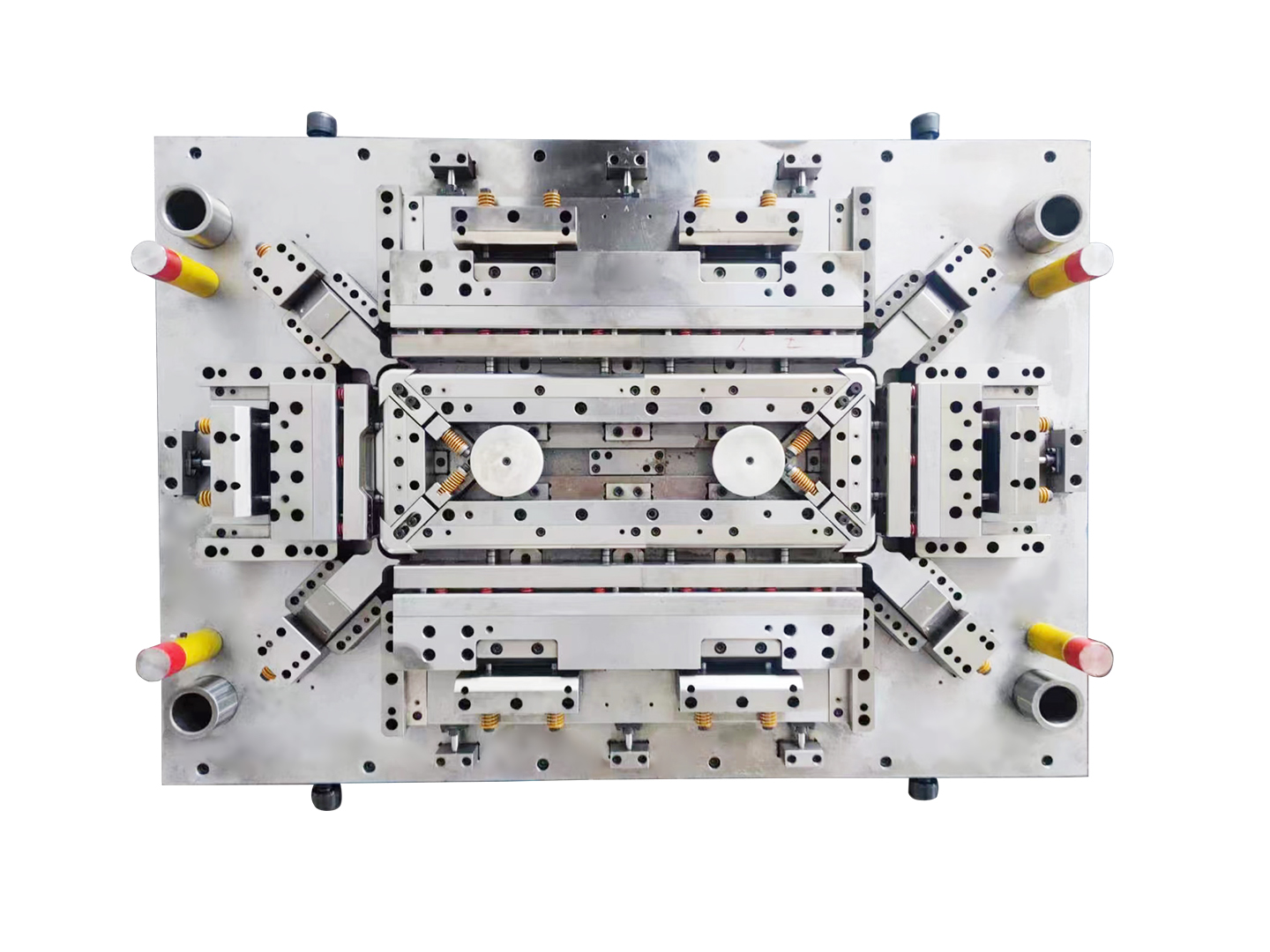

Stamping die manufacturing

Stamping die manufacturing and stamping forming service information | |

Name | Stamping Die |

Size | Customization |

Mold Type | Stamping die, sheet metal stamping die, metal stamping die |

Production time | 30 - 45days |

Combination type | Single process die ,compound die , progressive die |

Mold Materials | Cr12MoV、D2、DC53、SKD11、Cr4W2MoV、Cr5Mo1V、Cr6WV、S7... |

Manufacturing procedure | CNC\EDM\WEDM\Milling Machine\Grinding Machine... |

Forming Type | Blanking die, bending die, drawing die, forming die, three-dimensional pressing die |

Forming Process | Flanging, punching, bending,necking ,triming,cutting , forming,calender, drawing, finishing cold extrusion \ blanking \ expansion process |

Forming Material | Zinc-dipped steel SGCC, galvanized steel SECC, stainless steel SUS, tinned steel SPTE, aluminum/copper alloy plate, spring steel |

Capacity | Ten million pieces per month |

Service | Support Customization, Mold design, mold manufacturing, stamping production and complete one-stop solutions.。 |

Application | Car stamping parts ,door hinges , bracket , limiter , Reflector, shielding cover, alloy guide, beryllium copper shrapnel ,LED lamp housing , Metal connector, irregular stamping parts , stainless steel shrapnel, Electrical shell , chassis sheet metal ,connectors ,Heat sink , metal cans , gift box , food tray, canteen |

Keywords :

Stamping metal mold , metal stamping die , stamping tooling ,metal stamping , metal forming, stamping auto parts , household stamping parts ,

stamped hardware,stamping alumium clips , stamping keyboard housing , stamping metal enclosure,stamping manufacturer ,mold manufacturing,stamping electronic parts,stamping hardware parts,custom stamping parts , OEM stamping molds

Descriptions :

Metal stamping is a cold metal processing that applies pressure to the stamping die through a punch press machine to shape the iron material into the product parts.

Therefore, stamping processing requires stamping molds, which are indispensable equipment in production. The quality of stamping molds is positively related to processing, production efficiency and finished products.

The quality of the stamping die is crucial, it will highly affects in terms of production efficiency, lower maintenance rate and the quality of the product. With the low quality of the stamping die, will potentially occurs the risk of cracking or even collapse due to the high pressure.

Classification of Stamping Die:

1. Drawing die: It is a mold making method that changes the shape and size of sheet blanks into open hollow parts.

2. Forming mold: It is a mold that directly copies the blank or semi-finished workpiece according to the shape of the convex and concave mold as shown in the figure, and the material itself only produces a partial mold. For example, shrinking mold, expanding mold, undulating mold, shaping mold, etc.

3. Blanking die: A die that separates materials along open or closed contours. For example, punching dies, cutting dies, incision dies, trimming dies, etc.

4. Riveting mold: It uses external force to connect the participating parts together in a specified order and method to form a whole.

5. Bending mold: A workpiece mold that uses a sheet blank along a straight/bending line to obtain a specific angle and shape.

Classification by Stamping Process :

1. Single-process mold: This process is a mold that completes one stamping process in a single stroke of the press.

2. Composite mold: This process is a single station, and more than two stamping process molds are completed in one stroke of the press.

3. Continuous mold: A mold that has more than two stations in the feeding direction of the sheet and completes more than two stamping processes at different stations in a single stroke of the press.

4. Transfer mold: combines the advantages of single engineering mold and continuous mold, and realizes high-efficiency transfer of products through the robot transfer system. It can not only improve production efficiency, reduce the production of finished products, but also stabilize product quality.

Process method :

1. Punching and shearing dies: The work is completed by shearing. Commonly used forms in the industry include shearing dies, blanking dies, edge forming dies, drawing punches and punching dies.

2. Bending mold: It bends flat to rough blanks into specific shapes. However, it depends on the shape of the part, production volume and accuracy to produce many different forms of molds, such as cam bending dies, curling dies, bending dies and other special dies.

3. Drawing mold: It is to make a flat blank into a bottomed and seamless container.

4. Forming die: refers to the use of various local deformation methods to change the shape of the blank. The forms include convex forming dies, curling edge forming dies, round edge forming dies, etc.

5. Compression mold: It uses huge pressure to deform the metal blank. Its forms include embossing dies, imprinting dies, and end-pressure dies.