In the microscopic world of precision manufacturing, a difference of a millimeter can lead to a world of difference in product performance. Whether it is the processing of blades for aerospace engines or the assembly of precision electronic components, the ultimate pursuit of dimensional accuracy always runs through the entire process of processing and manufacturing. Understanding and rationally using tolerances and allowances is not only the key to ensuring product quality, but also the cornerstone for promoting processing and manufacturing to move towards high precision and intelligence.

Definition of tolerance and allowance

Tolerance

Refers to the amount of variation allowed in part size and geometric parameters. In the design drawing of the part, each dimension is marked with the basic size and tolerance range.

Allowance

Refers to a layer of material reserved on the part processing surface in advance during the machining process to ensure that the subsequent processing steps can achieve the design requirements of size, shape and surface quality.

Advantages and characteristics of tolerance and allowance

Ensure product interchangeability

Reasonable tolerance design allows parts of the same specification to be interchangeable within a certain error range, reducing assembly difficulty and improving production efficiency.

Reduce processing difficulty and cost

The existence of tolerance allows the selection of relatively economical processing methods and equipment within a certain range, avoiding unnecessary costs due to the pursuit of excessive precision. The reserve of allowance provides correction space for dimensional deviations during processing, reduces scrap rate, and reduces production costs.

Adapt to uncertainty in the processing process

In actual processing, factors such as machine tool accuracy, tool wear, and material performance fluctuations will affect the processing results. Tolerance and allowance provide a buffer for these uncertain factors, ensuring that even if there are certain processing errors, the parts can still meet the design requirements.

Ensure product performance and quality

The reasonable setting of allowance can ensure the final surface quality and mechanical properties of the parts. By gradually removing the allowance, defects and hardened layers on the surface of the blank can be eliminated, so that the surface of the part meets the requirements of smoothness and flatness, while ensuring the performance indicators of the part such as strength and hardness.

Types of tolerances and allowances

Types of tolerances

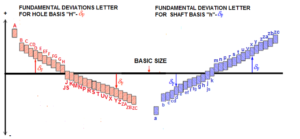

Dimensional tolerance

Refers to the amount of variation in the allowed size, which is used to control the linear dimensions of parts, such as length, diameter, width, etc. It directly affects the fit accuracy between parts, and can be divided into clearance fit, interference fit, and transition fit tolerances according to the nature of the fit.

Form tolerance

Used to limit the geometric shape errors of the surface of parts, such as straightness, flatness, roundness, cylindricity, etc. For example, the cylindricity of shaft parts in mechanical processing needs to be within a certain tolerance range to ensure stability during rotation.

Position tolerance

Used to limit the mutual position errors between the elements on the parts, such as parallelism, perpendicularity, coaxiality, etc. In the processing of box-type parts, the parallelism and perpendicularity tolerance control between holes is very important, which directly affects the installation and transmission accuracy of shaft parts.

Types of allowances

Process allowances

Refers to the thickness of the metal layer removed by a certain processing process, which is the difference between the process sizes of two adjacent processes. For example, in turning, the rough turning process reserves a larger allowance to quickly remove most of the excess material; the fine turning process reserves a smaller allowance to ensure the final dimensional accuracy and surface quality.

Total machining allowances

Refers to the thickness of all metal layers removed from the part from the blank to the finished product, which is equal to the sum of the allowances of each process. The size of the total machining allowance depends on the manufacturing accuracy of the blank and the final accuracy requirements of the part.

Application fields of tolerance and allowance

Mechanical manufacturing

From precision engine parts to ordinary mechanical structural parts, strict tolerance control and allowance setting are required to ensure accurate fit and stable operation between parts.

Aerospace

The aerospace field has extremely high requirements for the accuracy and reliability of parts. The precise design and control of tolerances and allowances can ensure the stable performance of key parts such as aircraft engine blades and fuselage structural parts in extreme environments and ensure flight safety. For example, the dimensional tolerance of aircraft engine turbine blades is controlled at the micron level, and the reserve of allowances is also accurately calculated to ensure the aerodynamic performance and strength of the blades.

The mass production of automotive parts depends on the scientific management of tolerances and allowances. Through reasonable tolerance design, the interchangeability and efficient assembly of parts can be achieved; through accurate allowance control, the processing quality and cost control of parts can be guaranteed. For example, the processing of automobile engine cylinder blocks requires precise control of the tolerances and processing allowances of each aperture to ensure the power performance and reliability of the engine.

Tolerances and allowances are also indispensable in the processing and assembly of electronic components. For processes such as precision chip packaging and circuit board manufacturing, even small dimensional deviations may affect product performance. Therefore, strict tolerance control and appropriate margin settings can ensure the accuracy and stability of electronic components and improve the quality and reliability of electronic products.

Chongqing Xuanmin Technology Factory has been deeply engaged in the field of processing and manufacturing for many years. It has profound technical accumulation and rich practical experience in the control of tolerances and allowances, and is committed to providing customers with high-precision, high-quality processing and manufacturing solutions.

We have introduced internationally leading CNC machining centers, high-precision grinders, three-coordinate measuring machines and other equipment, with micron-level processing accuracy and detection capabilities. Our five-axis linkage machining center can achieve high-precision processing of complex curved parts and strictly control the tolerance range; the three-coordinate measuring machine can perform all-round dimensional inspection of parts to ensure accurate removal of allowances and meet customers' stringent requirements for precision.

We provide personalized customization services. Whether it is high-precision aerospace parts or mass-produced automotive parts, we can tailor processing technology and tolerance control solutions according to customer needs to meet the diverse needs of customers.