From reducing weight and increasing efficiency of passenger planes at an altitude of 10,000 meters to breaking through the range of new energy vehicles on urban roads, light metals are reshaping the manufacturing landscape of modern industry and becoming the core material that drives technological leaps in various industries.

Definition of Light Metal

Light metal usually refers to metals and their alloy materials with a density below 4.5g/cm³. Compared with traditional metals such as steel, it has significant quality advantages while maintaining certain strength and functionality.

Advantages and characteristics of light metals

Significant weight reduction effect

Take aluminum alloy as an example, its density is about one-third of steel, and magnesium alloy is only one-quarter of steel. In automobile manufacturing, the use of light metals to replace traditional steel can reduce the weight of the whole vehicle by 10%-30%, effectively reduce fuel consumption and carbon emissions, and increase the cruising range of new energy vehicles.

Excellent comprehensive performance

Some light metals have excellent strength and hardness while reducing weight.

Good processing formability

Light metals have good ductility and plasticity, and can be processed into parts with complex shapes through various processes such as casting, forging, extrusion, and stamping.

High recycling rate

Most light metals are recyclable materials, with low energy consumption and small performance loss during the recycling process.

Excellent thermal and electrical conductivity

Some light metals, such as aluminum and magnesium alloys, have good thermal and electrical conductivity.

Types of light metals

Aluminum alloy

It is the most widely used light metal, commonly used in aerospace parts and bicycle frames; 7075 aluminum alloy has high strength and is suitable for high-end mold manufacturing and military products.

Magnesium alloy

It is the metal structural material with the lowest density, with high specific strength and good shock absorption.

Titanium alloy

It has excellent properties such as high strength, low density, high temperature resistance and corrosion resistance.

Beryllium alloy

It has the characteristics of high specific stiffness and low thermal expansion coefficient. It is mainly used in precision instruments in aerospace, inertial navigation systems and other fields with extremely high requirements for dimensional stability.

Application fields of light metals

Aerospace

Aircraft manufacturers such as Boeing and Airbus use a large number of aluminum alloys and titanium alloys to manufacture fuselages, wings, and engine parts to reduce the weight of aircraft and improve fuel efficiency; in rocket manufacturing, magnesium alloys are used to manufacture rocket body structural parts to reduce launch weight and improve carrying capacity.

Car companies such as Tesla use aluminum alloy body frames and magnesium alloy parts to achieve lightweight vehicles and extend driving range; at the same time, aluminum alloy wheels have become standard parts for cars due to their beautiful appearance and good heat dissipation.

In 3C products such as mobile phones and laptops, light metals are used to manufacture shells, heat dissipation modules, etc.

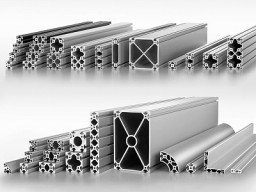

Architectural decoration

Aluminum alloy profiles are widely used in doors and windows, curtain walls, interior decoration and other fields due to their corrosion resistance, easy processing and beautiful appearance.

Sporting goods

Aluminum alloy bicycle frames are deeply loved by cycling enthusiasts for their light weight and high strength; titanium alloy golf clubs can improve the accuracy and distance of shots, becoming the preferred material for high-end sports equipment.

Lightweight metals, with their unique performance advantages, have become the core materials that promote the development of modern industry. As a professional manufacturer of lightweight metal products, our factory has been deeply involved in the industry for many years. With excellent technical strength and perfect service system, we provide customers with full-process solutions. We look forward to working with you to create an efficient and green industrial future!