In the era of manufacturing industry pursuing high efficiency, precision and reliability, the limitations of traditional packaging technology are becoming increasingly prominent, and it is difficult to meet the stringent requirements of electronics, automobile, medical and other industries for product miniaturization, high integration and high protection. Low-pressure injection molding technology came into being, bringing a new solution to the product packaging field with its innovative process principles and excellent performance.

Definition of low-pressure injection molding

Low-pressure injection molding is a process technology that uses low injection pressure (usually between 10-100bar) to inject hot melt adhesive material into the mold cavity, quickly solidify it in a short time, and achieve encapsulation and protection of electronic components and parts.

Advantages and characteristics of low-pressure injection molding

Low pressure, high-precision packaging

The lower injection pressure effectively reduces the risk of damage to internal sensitive components, and is particularly suitable for the packaging of pressure-sensitive electronic chips, sensors and other components.

Rapid prototyping, high production efficiency

Hot melt adhesive materials have the characteristics of rapid curing, and the curing process can usually be completed within a few seconds to tens of seconds. Compared with traditional injection molding or potting processes, it greatly shortens the production cycle, improves production efficiency, and meets the needs of large-scale industrial production.

Environmental protection and energy saving

The hot melt adhesive materials used in low-pressure injection molding are mostly environmentally friendly thermoplastic materials, which do not contain harmful solvents and volatile organic compounds. During the production process, no waste gas, waste liquid and other pollutants will be generated, which meets environmental protection requirements.

Good physical and chemical properties

The cured hot melt adhesive encapsulation layer has excellent physical and chemical properties, such as high insulation, waterproofness, chemical corrosion resistance, high and low temperature resistance, etc.

Flexible design and customization

The low-pressure injection molding process can design a variety of molds and packaging solutions according to the different needs of the product.

Types of low-pressure injection molding

Single-component low-pressure injection molding

Use a single-component hot melt adhesive material, which can be used for injection molding after heating and melting, without mixing with other components.

Two-component low-pressure injection molding

Use two different hot melt adhesive materials, usually component A and component B, and mix the two materials in a certain proportion before injection molding and inject them into the mold.

Insert low-pressure injection molding

During the injection molding process, the pre-prepared inserts of metal, plastic or other materials are placed in the mold, and then hot melt adhesive is injected to make the hot melt adhesive and the insert tightly combined to form a whole.

Application fields of low-pressure injection molding

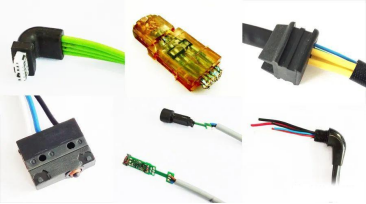

It has wide applications in electronic component packaging, circuit board protection, connector sealing, etc.

It is used for packaging and protection of automotive electronic control units (ECUs), sensors, wiring harness connectors and other components.

Medical equipment

It is suitable for packaging of medical sensors, implantable medical devices, portable medical devices, etc.

Communication field

It plays an important role in communication base stations, optical fiber connectors, network equipment, etc.

Aerospace

It is used for packaging of electronic equipment, sensors, cable connectors and other components in the aerospace field.

Low-pressure injection molding technology, with its unique advantages and wide applications, is becoming an indispensable key process in modern manufacturing. It not only meets the needs of various industries for high performance and high reliability of products, but also provides strong support for innovative design and functional expansion of products.

Our factory has the R&D and application of low-pressure injection molding technology, industry-leading technical strength and rich production experience, and is committed to providing customers with one-stop low-pressure injection molding solutions. We look forward to working with you to explore the infinite possibilities of low-pressure injection molding technology, empower your products, and create a brilliant future together!