With the booming automotive industry, welding technology plays an irreplaceable core role in the transformation of a car from parts to a complete vehicle. From improving the lightweight and safety of cars to leaps in production efficiency, every innovation in welding technology has pushed the automotive manufacturing industry to new heights.

Definition of welding in the automotive industry

Welding in the automotive industry refers to the process of forming permanent connections between automotive metal parts through atomic bonding and diffusion using heating, pressure or a combination of both, with or without filler materials, during the production of automotive parts and complete vehicles.

Advantages and characteristics of welding in the automotive manufacturing industry

Ensure the safety of the body structure

The welding quality directly determines the strength and rigidity of the car body. The high-quality welding process can effectively absorb and disperse the energy of the body frame during a collision, protecting the safety of the driver and passengers.

Assist in lightweighting of automobiles

With the increasing requirements for energy conservation, emission reduction and fuel economy, lightweighting of automobiles has become a trend. Welding technology can connect lightweight materials of different materials and thicknesses (such as aluminum alloys and high-strength steel) together, while ensuring the strength of the body and reducing the weight of the vehicle.

Improve production efficiency

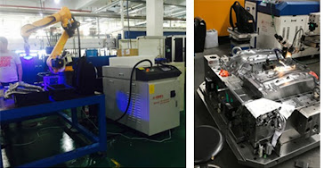

The widespread application of automated welding equipment and production lines has greatly improved the efficiency of automobile welding production. The robot welding system can achieve 24-hour uninterrupted operation, with fast welding speed and high precision, reducing the time and error of manual operation.

Achieve precise connection

Advanced welding technologies, such as laser welding and electron beam welding, can achieve precise control of welding position and welding parameters, ensuring tight connection and accurate size between parts.

Reduce production costs

Scaled welding production and optimization of welding processes improve material utilization, reduce waste generation and labor costs.

Types of welding in the automotive manufacturing industry

Resistance spot welding

Resistance spot welding is one of the most widely used welding methods in the automotive manufacturing industry. Pressure is applied through electrodes, and the resistance heat generated by the current passing through the contact points of the weldment is used to melt the metal at the contact points to form welds.

Laser welding

Laser welding uses a high-energy-density laser beam to quickly melt the weldment locally and cool and solidify it to achieve connection. It has the advantages of fast welding speed, narrow weld, small heat-affected zone, and high strength. It is often used for splicing of automobile bodies, welding of roofs and side panels, etc.

Arc welding

Includes manual arc welding, carbon dioxide gas shielded welding (CO₂ welding), etc. CO₂ welding uses carbon dioxide gas as a shielding gas, and has the characteristics of low cost, high welding efficiency, and deep penetration. It is widely used in the welding of automobile chassis, frames and other parts. Manual arc welding is suitable for welding operations in some complex structures or maintenance scenarios.

Friction stir welding

Friction stir welding is a solid-state welding method that generates heat through the friction between the stirring head and the weldment, plasticizes the local metal of the weldment, and realizes the solid-phase connection of the metal under the action of the stirring head.

Electron beam welding

Electron beam welding uses a high-speed electron beam to impact the surface of the weldment, converting kinetic energy into heat energy, so that the weldment melts and welds.

Application fields of welding in the automobile manufacturing industry

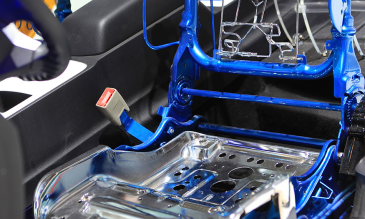

The body is the most concentrated application field of automobile welding technology. For example, the various components of the body frame are connected into a whole through resistance spot welding, and then the body side and other parts are optimized by laser welding to improve the overall performance of the body.

The welding of the automobile chassis mainly involves components such as the frame, suspension system, and transmission system.

The internal components of the engine and gearbox have complex structures and high precision requirements. Welding technology plays a key role in the manufacture of these components.

In the field of new energy vehicles, the welding of the battery system is crucial. For example, the welding of lithium battery tabs usually adopts laser welding, which can achieve high-precision and high-quality connections, reduce the resistance inside the battery, and improve the battery's charging and discharging performance.

As the core process of automobile production, welding technology in the automobile manufacturing industry plays an irreplaceable role in ensuring automobile safety performance, promoting automobile lightweighting, and improving production efficiency.

Our factory has rich experience and leading technical strength in the field of welding in the automotive manufacturing industry, and is committed to providing customers with high-quality welding solutions. Welcome friends from all walks of life to visit our factory for inspection and discuss cooperation! Here, you will personally experience the charm of advanced welding technology and understand how we use professionalism and craftsmanship to create each welding product.