Copper and copper alloys have become "all-round players" in the industrial field due to their excellent electrical conductivity, thermal conductivity and corrosion resistance. From ancient bronze tripods to modern precision electronic components, the application of copper has always been closely linked to technological innovation. The welding of copper and copper alloys has promoted the innovative development of the electrical, electronic, energy and other industries, and has become an indispensable core process in modern industry.

Definition of copper and copper alloy welding

Copper and copper alloy welding is a process that uses heat, pressure or both to achieve metallurgical bonding between copper and copper alloy base materials and filler materials (or no filler materials) at the atomic level to form a strong welded joint.

Advantages and characteristics of copper and copper alloy welding

Excellent electrical and thermal conductivity

Copper and copper alloys are excellent electrical and thermal conductive materials. The electrical and thermal conductivity of the joint after welding is close to that of the parent material, which is suitable for scenes with extremely high requirements for current and heat transfer, such as power busbars, electronic component connections, etc.

Corrosion resistance enhancement

By rationally selecting welding materials and processes, a dense oxide film can be formed on the surface of the welded joint to improve corrosion resistance. For example, tin bronze welded joints can still maintain stable performance in seawater environments and are suitable for fields such as ships and marine engineering.

High process flexibility

Copper and copper alloy parts of different thicknesses and shapes can be welded, from micron-level electronic chip pins to millimeter-level industrial pipelines, all of which can be precisely connected through customized processes.

Stable joint performance

By controlling the heat input during welding, the coarseness of the parent material grains can be reduced, ensuring the strength, plasticity and fatigue resistance of the joint, and meeting the requirements of high-load conditions, such as motor windings, high-voltage electrical switches, etc.

Types of copper and copper alloy welding

Classification by welding method

TIG welding (tungsten inert gas welding)

uses tungsten as the electrode, and argon gas protects the welding area. It is suitable for welding thin plates and precision parts, such as copper alloy jewelry and electronic component packaging.

MIG welding (metal inert gas welding)

by melting the welding wire to fill the joint, it can weld medium and thick plates. It has high efficiency and deep penetration. It is often used for welding copper pipes and structural parts.

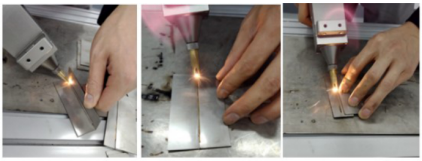

Laser welding

uses high-energy laser beams to achieve rapid welding, with a small heat-affected zone, suitable for welding ultra-fine and ultra-thin parts, such as lithium battery pole pieces and precision electronic connectors.

Resistance welding

generates heat by passing current through the contact point of the workpiece to achieve rapid welding. It is suitable for lap joints and spot welding scenarios, such as copper alloy automotive parts and relay contacts.

Classification by alloy type

Pure copper welding

Use deoxidized copper welding wire (such as T2, TU1) to prevent welding pores, suitable for high-purity conductive parts such as power transformer windings.

Brass welding

Use welding wire with matching zinc content (such as H62, H68) to control zinc evaporation and ensure joint strength, suitable for corrosion-resistant parts such as valves and radiators.

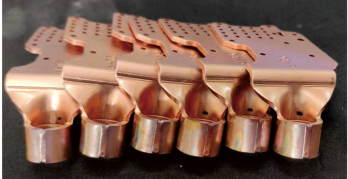

Bronze welding

Select special welding wire according to the alloy composition (tin bronze, aluminum bronze, etc.) to improve wear resistance and corrosion resistance, suitable for heavy-loaded parts such as bearings and ship propellers.

Application fields of copper and copper alloy welding

Electrical and electronic

Power system: copper busbar welding, transformer winding connection, to ensure low resistance and high stability.

Energy and power

New energy: lithium battery tab welding, fuel cell bipolar plate connection, to ensure efficient energy transmission.

Architecture and decoration

Architectural hardware

copper door and window welding, decorative line splicing, both aesthetic and weather resistance.

Bathroom equipment

copper water pipe welding, faucet component connection, to ensure water quality safety and service life.

Whether you are looking for custom CNC machined stainless steel alloys for automotive, aerospace or construction, Xuanmin's custom copper processing products are your ideal choice. Partner with us to gain in-depth knowledge of the processing of copper and other materials.