With the rapid development of science and technology, the manufacturing industry is undergoing profound changes. CNC lathes, with their excellent performance, have brought unprecedented precision and efficiency to the manufacturing industry.

Definition of CNC lathe

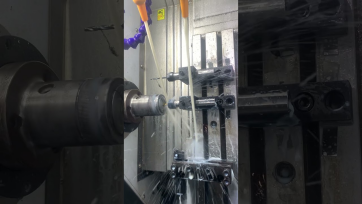

CNC lathe, full name digital control lathe, is a machine tool that uses digital information to control the movement and processing of the lathe. It uses a computer control system to convert the instructions in the processing program into the movement of each coordinate axis of the lathe, thereby accurately controlling the relative position and movement trajectory between the tool and the workpiece, and realizing the turning of the workpiece.

Advantages and characteristics of CNC lathes

High-precision processing

CNC lathes are equipped with high-precision transmission components and position detection devices, which can control the processing accuracy within a very small tolerance range and meet the industry with extremely high requirements for component precision.

High-efficiency production

It has a high degree of automation and can complete continuous processing of multiple processes in one clamping, reducing the clamping and adjustment time of workpieces and greatly improving production efficiency.

High flexibility

It only needs to modify the processing program to easily adapt to the processing needs of workpieces of different shapes and sizes, without the need to re-manufacture complex tooling and fixtures, which provides great convenience for multi-variety and small batch production and effectively reduces production costs.

Stable processing quality

The processing process is precisely controlled by the program, which reduces the impact of human factors on processing quality, ensures the consistency and stability of product quality, and improves the product qualification rate.

Types of CNC lathes

Horizontal CNC lathes

This is the most common type, with the spindle placed horizontally.

Vertical CNC lathes

The spindle is arranged vertically, suitable for processing disc parts with large diameter and short length, such as large flanges, end caps, etc. Its worktable has a strong load-bearing capacity and can ensure the stability of the processing process.

Special CNC lathes

Designed and manufactured for specific industries or special parts processing needs, such as camshaft CNC lathes, crankshaft CNC lathes, etc., with strong pertinence and professionalism.

Application fields of CNC lathes

Aerospace

Used to manufacture high-precision and high-strength parts such as engine blades, landing gear parts, and aircraft structural parts to ensure the reliability and safety of aviation equipment.

Manufacture key automotive parts such as engine cylinder blocks, cylinder heads, crankshafts, and drive shafts to meet the automotive industry's requirements for high-precision, high-efficiency, and mass production of parts.

Medical equipment

Processing artificial joints, dental equipment, medical equipment parts, etc., because of its high precision, it can ensure the good compatibility of medical equipment with human tissue.

Manufacture precision housings, connectors, shaft parts, etc. of electronic equipment to meet the characteristics of miniaturization and high precision of electronic products.

With its unique advantages, CNC lathes have become the core equipment for modern manufacturing to achieve high-precision and high-efficiency production. Xuanmin Factory has advanced CNC lathe equipment, and the professional technical team will explain the operation, processing and application cases of CNC lathes in detail. Whether it is consulting on equipment performance or seeking customized processing solutions, we will serve you wholeheartedly. We look forward to your arrival and start the journey of precision manufacturing of CNC lathes together.