As the global manufacturing industry continues to seek breakthroughs and innovations, the traditional manufacturing model faces challenges such as rising costs, efficiency bottlenecks, and rapid response to market demand. From intelligent collaboration on the production line to precise management of the supply chain, artificial intelligence is reshaping the manufacturing industry and becoming the core force driving the manufacturing industry towards high-end and intelligent development.

Definition

Artificial intelligence in manufacturing refers to the application of artificial intelligence technologies, including machine learning, deep learning, natural language processing, computer vision, etc., to all aspects of manufacturing to achieve automation and intelligence in the production process, improve production efficiency and product quality, optimize supply chain management, and enhance the company's ability to respond to market changes. Through the collection, analysis and learning of large amounts of production data, artificial intelligence systems can simulate human thinking and decision-making processes, and autonomously complete complex tasks such as equipment failure prediction, production process optimization, quality inspection, etc., providing technical support for the transformation and upgrading of the manufacturing industry.

Advantages and features

Improve production efficiency

Automated equipment and systems driven by artificial intelligence can work tirelessly and continuously, and their operating speed and accuracy far exceed that of humans.

Improve product quality

Using computer vision technology, artificial intelligence can perform real-time and high-precision quality inspections on products.

Enhance equipment maintenance and management

Artificial intelligence can predict equipment failures in advance through real-time monitoring and analysis of equipment operation data.

Optimize supply chain management

In the supply chain, artificial intelligence can process massive amounts of supply chain data, including supplier information, inventory levels, logistics and transportation, etc. Through data analysis and prediction, accurate inventory management can be achieved to avoid inventory backlogs or out-of-stock phenomena.

Achieve personalized customized production

As market demand shifts towards personalization and customization, artificial intelligence helps the manufacturing industry achieve flexible production. Through the analysis and understanding of customer needs, the production system can quickly adjust production parameters and processes to achieve rapid switching of production of products of different specifications and styles.

Application areas

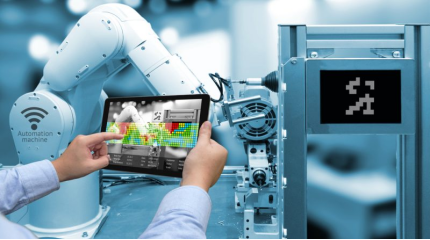

Intelligent production and manufacturing

On the production line of the factory, artificial intelligence is widely used in automated processing, assembly and testing. For example, electronic manufacturing companies such as Foxconn have introduced a large number of intelligent robots to assemble and test electronic products.

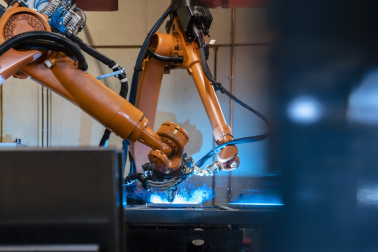

Quality control and testing

In industries such as automobile manufacturing and mechanical processing, quality control is crucial. The computer vision technology of artificial intelligence can perform all-round and high-precision inspections on products. For example, during the production process, BMW uses an artificial intelligence-based visual inspection system to inspect the welding quality of the car body and the installation accuracy of parts, so as to promptly discover and correct quality problems in the production process and ensure that every car off the line meets strict quality standards.

Equipment maintenance and fault prediction

In the fields of aerospace manufacturing, energy and electricity, the reliability of equipment is directly related to production safety and economic benefits. By analyzing the vibration, temperature, pressure and other data during the operation of the equipment, the possible failure of the equipment can be predicted in advance, and maintenance can be arranged in time to avoid production interruptions and safety accidents caused by sudden equipment failures.

Supply chain and logistics management

Manufacturing giants such as Amazon use artificial intelligence to optimize their supply chain and logistics management. Use machine learning algorithms to predict commodity demand, arrange inventory reasonably, and reduce inventory costs. At the same time, in the logistics and distribution link, the intelligent path planning system can plan the optimal route for the delivery vehicle based on real-time traffic information, improve delivery efficiency, reduce logistics costs, and achieve fast and accurate delivery of goods.

Product Design and R&D

In the process of electronic product development, artificial intelligence can assist designers in product design. For example, Google's AutoML technology can automatically generate electronic product design plans based on market demand and user feedback, and optimize the design through simulation testing, shorten the product development cycle, and reduce R&D costs.

Artificial intelligence in manufacturing has gradually moved from concepts to widespread application. With the continuous advancement of artificial intelligence technology, such as the integration of quantum computing and artificial intelligence, and the emergence of more powerful algorithm models, the future manufacturing industry will usher in a new era of greater intelligence and automation. Artificial intelligence will continue to work hard in all aspects of the manufacturing industry, injecting a steady stream of power into the innovative development of the manufacturing industry, helping the manufacturing industry to open a new chapter in the global economic competition and achieve sustainable high-quality development.