In the complex system of modern industrial production, stamping dies and tools promote the efficiency and precision of product manufacturing. From the precision molding of automotive parts to the mass production of electronic product shells, they are everywhere, continuously outputting high-quality products for various industries, and profoundly affecting every aspect of our lives and production.

Definition of stamping dies and tools

Stamping dies

A special process equipment used to process materials (metal or non-metal) into parts (or semi-finished products) in cold stamping, commonly known as cold stamping dies. It uses the pressure provided by the press to make the material plastically deform under the specific shape and size restrictions of the die, thereby obtaining the required part shape and dimensional accuracy.

Stamping tools

Refer to various auxiliary equipment used in conjunction with stamping dies during the stamping production process, including punching machines, feeding devices, material removal devices, testing tools, etc. These tools and stamping dies together constitute a complete stamping production system to ensure the smooth progress of the stamping process and improve production efficiency and product quality.

Advantages and features of stamping dies and tools

Efficient production

Stamping dies and tools can achieve high-speed and continuous stamping processing, and produce a large number of parts of the same specifications in a short time. High precision and high consistency

The stamping dies are precisely designed and manufactured to ensure the dimensional accuracy and shape consistency of the parts. The dimensional tolerance of the stamped parts can be controlled within a very small range to meet the needs of industries with strict precision requirements, such as electronics, aerospace and other fields.

High material utilization rate

In the stamping process, by reasonably designing the layout of the die, the raw materials can be maximized and the generation of waste can be reduced.

Complicated shapes can be processed

Stamping dies can process various complex parts, from simple flat parts to complex structural parts with three-dimensional shapes, which can be achieved through appropriate die design and stamping process.

Good surface quality

The surface of the parts after stamping is smooth, without cutting marks, and has good surface quality.

Types of stamping dies and tools

Types of stamping dies

Single-process die: a die that only completes one stamping process in one stroke of the press, such as blanking die, punching die, bending die, drawing die, etc. Single-process die has a simple structure, short manufacturing cycle, low cost, and is suitable for small-batch production or processing of parts with simple shapes.

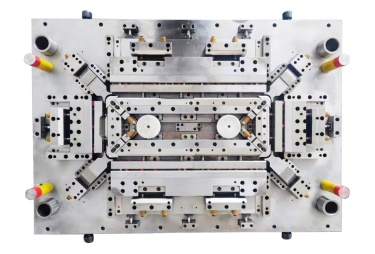

Compound die: a die that completes two or more stamping processes at the same position of the die in one stroke of the press. For example, a blanking-punching compound die can complete both blanking and punching processes in one stamping, with high production efficiency and high part precision, but the die structure is complex, the manufacturing difficulty is high, and the cost is high. It is suitable for mass production of parts with complex shapes and high precision requirements.

Progressive die: also known as continuous die, is a die that completes multiple stamping processes at different positions of the die in one stroke of the press. Progressive die has high production efficiency and can realize automated production. It is suitable for mass production of parts with complex shapes and high precision requirements.

Types of stamping tools

Punching machine:It is the core equipment of stamping production. According to its transmission mode, it can be divided into mechanical punching machine and hydraulic punching machine. Mechanical punching machine has high stamping speed and precision, and is suitable for large-scale and high-precision stamping production; hydraulic punching machine has large stamping force and good overload protection performance, and is suitable for stamping processing of large parts or thick plates.

Feeding device:It is used to automatically feed raw materials into the stamping die. Common feeding devices include roller feeder, pneumatic feeder, servo feeder, etc.

Removing device:After the stamping is completed, the parts are removed from the die. Common removable devices include manipulator, vacuum suction cup, etc.

Detection tool:It is used to detect the dimensional accuracy, shape accuracy, surface quality, etc. of stamping parts. Common detection tools include calipers, micrometers, projectors, three-coordinate measuring machines, etc.

Application fields of stamping dies and tools

Most of the covering parts, structural parts, and parts of automobile bodies are manufactured by stamping. For example, the covering parts of automobile doors, hoods, trunk lids, etc. are stamped by large stamping dies, which ensures the dimensional accuracy and surface quality of the parts; the structural parts of automobile frames, chassis, etc. are processed into complex shapes by stamping dies, which improves the strength and safety of the automobile.

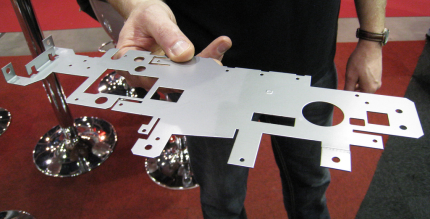

In the manufacture of electronic equipment, stamping dies and tools are used to manufacture the shells, pins, connectors, etc. of electronic components. For example, the metal shells of electronic products such as mobile phones and computers are processed by precision stamping dies, which have the characteristics of high precision and high surface quality; the pins and connectors of electronic components are stamped by progressive dies, which realizes efficient and accurate manufacturing.

The shells and parts of home appliances are also widely stamped. For example, the shells of household appliances such as refrigerators, washing machines, and air conditioners are processed into various shapes and sizes through stamping dies to meet the needs of different brands and models; the internal parts of household appliances, such as brackets and connectors, are also manufactured through stamping, which improves production efficiency and product quality.

In the manufacture of hardware products, stamping dies and tools are used to manufacture various hardware accessories, such as door locks, handles, hinges, screws, etc. Stamping can ensure the dimensional accuracy and surface quality of hardware accessories, improve production efficiency, and reduce production costs.

Aerospace

In the field of aerospace, stamping dies and tools are used to manufacture parts for aircraft, rockets, and other aircraft. For example, the wings, fuselages, engine parts, etc. of aircraft are processed into complex shapes and high-precision sizes through stamping dies, meeting the strict requirements of aerospace products for material properties and manufacturing accuracy.

As an important foundation of industrial manufacturing, stamping dies and tools play an irreplaceable role in many industries with their advantages of high efficiency, precision, and ability to process complex shapes. With the continuous advancement of science and technology and the increasing requirements of various industries for product quality and performance, stamping dies and tools are also constantly innovating and developing. New mold materials, advanced manufacturing processes, and intelligent stamping equipment continue to emerge, enabling stamping processing to achieve higher precision, more complex shape processing, and more efficient production.