In the field of metal processing, various surface treatment technologies are emerging to improve the performance of steel, extend its service life and meet diverse aesthetic needs. Among them, steel blackening technology has become a focus of attention in the industry with its unique advantages. It not only puts on a "new coat" of protection and decoration for steel materials, but also shows great application potential in many fields.

Steel blackening definition

Steel blackening is a treatment process that forms a black oxide film or coating on the surface of steel through specific chemical or physical methods. This black coating is not a simple dye, but a chemical reaction or strong adhesion with the steel matrix, thus giving the steel new characteristics.

Features of steel blackening

Excellent corrosion resistance

The dense oxide film or coating formed after blackening treatment effectively blocks oxygen, moisture and various corrosive media from direct contact with the steel matrix, significantly slows down the corrosion rate of steel, and greatly extends the service life of steel in harsh environments.

Enhanced wear resistance

Compared with untreated steel, the surface hardness after blackening is improved, and it can show stronger wear resistance when subjected to friction and wear.

Unique decorativeness

The uniform and deep black appearance gives steel a unique texture and beauty, meeting the diverse needs of different industries for product appearance.

Good electromagnetic shielding performance

The material after steel blackening treatment has a certain shielding effect on electromagnetic signals, which can effectively reduce the electromagnetic interference between the internal components of electronic equipment and ensure the stable operation of the equipment.

Steel blackening treatment method

Chemical oxidation method

This is a more common steel blackening treatment method. The steel is immersed in a solution containing specific chemical agents, such as an alkaline solution containing sodium hydroxide, sodium nitrite and other ingredients. Under certain temperature and time conditions, the solution reacts chemically with the surface of the steel, and the iron atoms are gradually oxidized to form a black ferroferric oxide film. In this process, the concentration, temperature and treatment time of the solution need to be strictly controlled to ensure the quality and uniformity of the oxide film.

Hot-dip plating method

First, the steel is pretreated to remove impurities such as oil and rust on the surface to make the surface clean, and then the treated steel is immersed in a molten metal salt bath, usually a salt bath containing metal elements such as zinc and nickel. At high temperatures, the metal salt reacts with the surface of the steel to form a composite black coating containing metal oxides and metal plating. The coating formed by this method has strong bonding and better protective performance.

Physical Vapor Deposition (PVD)

In a high vacuum environment, metal source (such as chromium, titanium, etc.) atoms or ions are vaporized by heating evaporation or sputtering, and accelerated to deposit on the steel surface under the action of an electric field. These atoms or ions condense on the steel surface and react chemically to form a layer of metal compound coating with a black appearance.

Applicable materials for steel blackening

Almost all types of steel materials are suitable for blackening treatment, including common carbon steel, alloy steel, stainless steel, etc. However, due to the differences in chemical composition and organizational structure of steel of different materials, it may be necessary to adjust the processing parameters appropriately to achieve the best blackening effect and performance improvement. For example, stainless steel contains alloy elements such as chromium and nickel. When blackening by chemical oxidation, it may be necessary to appropriately increase the concentration of the oxidant in the solution or extend the treatment time to form an ideal black oxide film.

Application fields of steel blackening

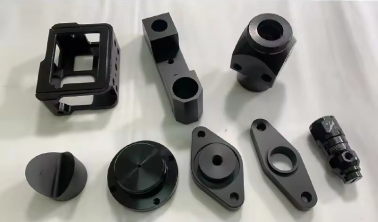

Mechanical manufacturing

In the manufacture of various mechanical parts, such as shafts, gears, chains, etc., steel blackening can improve the wear resistance of parts, reduce the frequency of equipment maintenance and replacement, and reduce production costs. For example, the key components such as crankshafts and connecting rods in automobile engines can operate stably under high temperature, high pressure, and high load working environments after blackening.

Electronic appliances

The housing, radiator, and internal connectors of electronic equipment are often treated with steel blackening. The blackened steel can not only provide good electromagnetic shielding performance to prevent electromagnetic interference inside electronic equipment, but also improve the appearance and texture of the product, meeting consumers' dual needs for the beauty and performance of electronic products.

Architectural decoration

In the field of construction, steel blackening can be used for building structural parts, door and window frames, decorative railings, etc. Its excellent corrosion resistance enables it to maintain a good condition for a long time in outdoor environments, and its unique black appearance adds a sense of solemnity and modernity to the building.

Military industry and national defense

In military products, such as parts of weapons and equipment, steel structures of military facilities, etc., the performance requirements of steel are extremely strict. Steel blackening treatment can enhance the corrosion resistance, wear resistance and concealment of steel, meeting the use requirements of military equipment in complex and harsh environments.

As a multifunctional steel surface treatment method, steel blackening technology plays an irreplaceable role in many industries with its unique advantages and characteristics. With the continuous advancement of science and technology and the continuous optimization of processes, steel blackening technology will show stronger vitality in the future, bring more innovation and development opportunities to the metal processing field, and promote various industries to move towards higher quality and more sustainable directions.