In the field of industrial manufacturing, brass has become an ideal material for the manufacture of many parts due to its excellent conductivity, corrosion resistance and processing performance. Among them, brass brushes and brass stampings play a key role in different application scenarios with their unique characteristics.

Brass brush, stamping concept

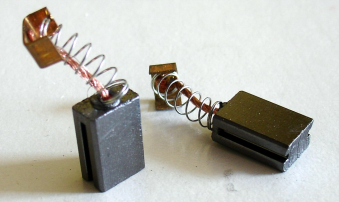

1. Brass brush

Brass brush is a component used in motors or electrical equipment to conduct current. It is usually made of brass wire or brass sheet, with good conductivity and wear resistance. During the operation of the motor, the brush is in close contact with the commutator or slip ring, and the current is transmitted through sliding friction to ensure the normal operation of the motor.

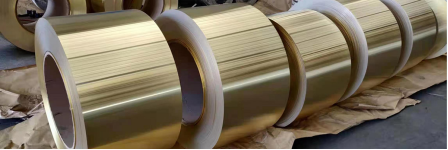

2. Brass stamping parts

Brass stamping parts are parts made of brass sheets or strips by stamping. Stamping is a processing method that uses a press and a die to apply pressure to the sheet to cause plastic deformation, thereby obtaining the desired shape and size.

The difference between brass brushes and stamping

(I) Manufacturing process

Brass brushes: mainly made by drawing, weaving or pressing.

Brass stamping parts: using stamping technology, using punch presses and dies to perform operations such as punching, bending, and stretching on brass sheets, directly processing the sheets into the required part shape.

(II) Structure and shape

Brass brushes: usually in the form of wire, strip or block, with a relatively loose structure to increase friction and conductivity with the contact surface. Its shape is generally simple, and is mainly designed according to the specifications and requirements of the motor.

Brass stamping parts: various shapes, can be designed into various complex geometric shapes according to product requirements, such as special-shaped holes, bent parts, stretched parts, etc.

(III) Performance characteristics

Brass brushes: the focus is on good conductivity and wear resistance, as well as a certain degree of flexibility to adapt to the dynamic changes of the contact surface. At the same time, the brush needs to have a low contact resistance to reduce power loss and heat generation.

Brass stamping parts: focus more on mechanical properties, such as strength, hardness and toughness, to meet the mechanical requirements in different working environments. In addition, depending on the application scenario, it may also be required to have good corrosion resistance, conductivity or other special properties.

Brass brushes and stamping application areas

(I) Brass brushes

Motor field

Widely used in DC motors, AC commutator motors, etc., as current conduction components to ensure the normal operation of the motor. For example, in the drive motor of an electric vehicle, brass brushes play a key role in current transmission.

Electrical equipment

Used in various equipment that requires sliding electrical connections, such as slip rings, collector rings, etc., to ensure stable power supply of the equipment during rotation or movement.

(II) Brass stamping parts

Electronic industry

Manufacturing housings, connectors, connectors, etc. of electronic equipment, such as metal parts in electronic products such as mobile phones and computers.

Automobile industry

Manufacturing various brass stamping parts in automobile engines, transmissions, chassis and other parts, such as automobile door locks, radiator fins, etc.

Machinery manufacturing

Used in manufacturing parts of various mechanical equipment, such as gears, bushings, brackets, etc., to meet the needs of different mechanical structures.

Brass brushes and brass stampings are two important forms of brass materials in the industrial field. With their unique characteristics and advantages, they play an irreplaceable role in different industries. With the continuous advancement of technology and the increasing diversification of market demand, both will continue to innovate and optimize in terms of material properties and manufacturing processes.

Xuanmin can customize and produce brass brushes and brass stampings of various specifications and performances according to the special needs of customers. Whether it is a small batch of sample trial production or large-scale mass production, we can respond quickly and provide customers with high-quality products and services.