In the modern manufacturing industry that pursues lightweight, high strength and functional integration, insert molding, as an efficient and flexible process, is becoming a core technology in the field of metal-plastic combination. Whether it is automotive electronic components, medical devices or smart home devices, insert molding provides a reliable solution for the production of complex parts with its unique advantages.

What is Insert Molding?

Insert molding is a manufacturing process where a pre-manufactured insert (usually metal) is embedded into a plastic part. This process allows the functionality of a metal part to be combined with the molding capabilities of plastic.

How to carry out the insert molding process

Mold design and insert pretreatment

Customize the mold according to product requirements, and clean, degrease or surface treat the metal insert (such as electroplating, sandblasting) to ensure adhesion with the plastic.

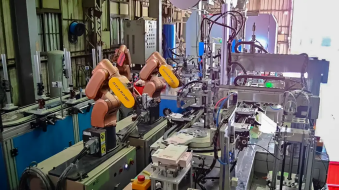

Precise positioning of inserts

Fix the metal parts in the predetermined position in the mold through automated equipment or manual work, and ensure positioning accuracy (usually the tolerance is controlled within ±0.1mm).

Injection molding

Inject high-temperature molten plastic (such as PA, PBT, PEEK, etc.) into the mold. The plastic fills the cavity under high pressure and wraps the metal insert to form an integrated structure.

Cooling and demoulding

After the plastic cools and solidifies, open the mold to take out the finished product to complete the firm combination of metal and plastic.

Core advantages of insert molding

Functional integration and lightweight

By combining the strength of metal and the lightness of plastic, the miniaturization and lightweight of complex functional components can be achieved.

Reduced assembly costs

Eliminate subsequent mechanical fastening or gluing steps, reducing labor and time costs.

High reliability

The physical combination of plastic and metal can improve shock resistance, sealing and durability, and is suitable for harsh environments.

Design freedom

Supports special-shaped structures and multi-insert combinations to meet customized needs.

Limitations of insert molding need attention

Process complexity

extremely high requirements for mold accuracy, insert positioning and injection molding parameters (temperature, pressure), requiring professional equipment support.

Material compatibility

The difference in thermal expansion coefficients between metals and plastics may cause stress cracking, and risks need to be avoided through material selection and process optimization.

High initial cost

large investment in mold development and automation equipment, suitable for medium and large batch production.

Main application areas of insert molding

Automotive industry

engine sensor housing, connectors, interior function buttons (metal contacts combined with plastic substrate).

Electronic appliances

5G communication module shielding cover, power plug metal terminals, smart wearable device structural parts.

Medical devices

surgical instrument handles, sterilizable equipment housings (combining metal rigidity and plastic insulation).

Household and industrial equipment

smart door lock components, power tool handles and other scenarios with high durability requirements.

The insert molding process, with its "1+1>2" synergistic effect, continues to drive the manufacturing industry towards efficiency and integration. In the face of the future trend of personalized customization and green manufacturing, this technology will unleash its potential in more fields through material innovation and intelligent upgrades (such as AI-driven process optimization).

As a technical service provider deeply engaged in the field of precision manufacturing, Xuanmin provides customers with a full-chain solution from design support, rapid prototyping to mass production with advanced insert molding equipment and mature process experience. Whether it is the problem of complex insert positioning or the selection of high-performance materials, we use technological innovation to enable product value upgrades.

Contact us now to start your journey of efficient insert molding production!