In modern manufacturing, the choice of cutting technology is crucial to production efficiency and product quality. Plasma cutting, as an advanced and efficient metal cutting process, uses high-temperature and high-pressure plasma flow to quickly melt metal and form precise cuts. Since the mid-20th century, plasma cutting technology has continued to evolve and has attracted more and more industry applications, especially in metal processing, automobile manufacturing, and construction, showing its unparalleled advantages.

Plasma cutting concept

Plasma cutting is a processing method that uses plasma (i.e., the gas in it is heated to a high temperature and ionized) to cut metal materials. It heats the gas (usually compressed air, oxygen or nitrogen) to a very high temperature, making it a conductive plasma state. Then, the plasma stream is ejected through the nozzle at a high speed to form a high-temperature, high-energy cutting beam. When the plasma stream comes into contact with the metal surface, it can quickly melt and blow away the metal to form a cut of the desired shape.

Features of plasma cutting

High cutting speed

Plasma cutting can process metal at an extremely fast speed, which is particularly suitable for large-scale production and emergency repair operations.

Wide adaptability

It can cut a variety of metal materials including carbon steel, stainless steel, aluminum, etc., and is particularly suitable for cutting metals of various thicknesses.

Excellent cutting quality

The cutting edge is usually smoother, reducing the need for post-processing, and the cutting accuracy is high.

Energy saving and environmental protection

Compared with traditional cutting methods, plasma cutting produces less smoke and gas, which is suitable for production environments with high environmental protection requirements.

Simple operation

With the development of technology, the operating interface of plasma cutting equipment is becoming more and more user-friendly, making it easier for operators to get started.

Flexibility

Plasma cutting machines can be operated manually or integrated into CNC systems to achieve automated cutting, which can meet diverse cutting needs.

Principles of Plasma Cutting

1. Gas Ionization

The process begins by passing a gas (usually air, but oxygen or nitrogen can also be used) through a nozzle and ionizing it with an electric arc. The ionization process converts the gas into a plasma that conducts electricity.

2. Plasma Stream Generation

The conductive plasma is ejected through a high-pressure nozzle. The high-temperature and high-pressure plasma stream can reach extremely high temperatures (up to 30,000°F or about 16,600°C), enough to melt most metals.

3. Cutting Process

When the plasma stream contacts the workpiece, it melts the metal. The molten metal is blown away by the high-speed gas stream, creating a cut in the workpiece.

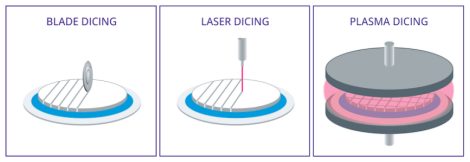

Types of Plasma Cutting

Handheld plasma cutters: For manual cutting, ideal for small projects and quick repairs.

Automated systems: CNC plasma cutters are used for large-scale production and complex designs, achieving precise and repeatable cuts.

Plasma Cutting Applications

Metalworking

Manufacturing metal parts in industries such as automotive manufacturing, aerospace, and construction.

Art and Architectural Design

Artists and designers use plasma cutting to create intricate metal carvings and architectural details.

Restoration and Maintenance

Quickly cutting metal is used in maintenance operations, especially in heavy industrial settings.

Plasma cutting has taken an important place in the metalworking industry with its fast, efficient and high-quality cutting capabilities. Despite certain limitations, its wide adaptability in a variety of processes and applications makes it the technology of choice in many manufacturing and design processes.

With the continuous development and innovation of technology, the future of plasma cutting will undoubtedly be brighter. Xuanmin has industrial-scale production lines, using plasma cutting technology to bring satisfactory products to many customers. Please submit your product catalog to speed up our cooperation!