Subtractive manufacturing is a traditional and mature manufacturing process that removes excess parts from solid materials to form the desired parts or products. This process usually involves metal, plastic or other materials, using a variety of tools and technical means, such as turning, milling, drilling, grinding, etc. In recent years, under the background of Industry 4.0 and smart manufacturing, subtractive manufacturing has not only been improved in accuracy and efficiency, but also combined with digital technology to better meet the needs of modern manufacturing for flexibility, personalization and automation.

Main steps of subtractive manufacturing

Material selection

Select suitable metal materials according to the requirements of the product, such as aluminum, steel, stainless steel, copper, etc.

Design and modeling

Three-dimensional modeling is performed through computer-aided design (CAD) software to determine the shape and size of the parts.

Programming

Use computer-aided manufacturing (CAM) software to generate processing programs for controlling CNC machine tools.

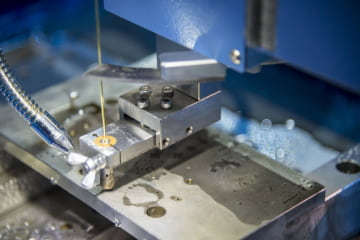

Fixtures and clamping

Clamp the material on the machine tool to ensure stability and accuracy during processing.

Processing operations

Use different machine tools (such as lathes, milling machines, laser cutters, etc.) to remove materials until the desired shape and size are obtained.

Post-processing

The processed parts are cleaned, deburred, heat treated, and surface treated to improve their performance and durability.

Advantages of subtractive manufacturing

High precision

Can achieve higher dimensional and surface finish requirements.

High material utilization

Suitable for material processing in mass production, especially for parts with complex shapes.

Wide range of applications

Can process metal parts of various shapes and sizes, suitable for a variety of industries.

Disadvantages of Subtractive Manufacturing

Material waste

A large amount of waste chips may be generated during the removal process.

Long production time

Subtractive manufacturing usually takes longer to prepare and process than additive manufacturing (such as 3D printing).

High equipment investment

High-precision CNC machine tools are expensive and require professional operating skills.

Applications of Subtractive Manufacturing

1. Aerospace

In the aerospace industry, subtractive manufacturing is used to manufacture complex parts such as engine components and fuselage structures. These parts often require high strength, high temperature resistance, and performance under extreme conditions, and subtractive processing can meet these stringent requirements.

The automotive industry uses subtractive manufacturing to produce engine components, gearboxes, chassis, etc. Through high-precision cutting technology, the precise fit between parts is ensured, thereby improving the performance and safety of the entire vehicle.

3. Medical Devices

In the production of medical devices, subtractive manufacturing is used to manufacture a variety of precision surgical instruments and implants. These products often require sterile and high-precision processing to ensure the safety and effectiveness of the operation.

The electronics industry uses subtractive manufacturing to process metal housings, heat sinks and other components to ensure the product's heat dissipation performance and beautiful appearance, while avoiding interference with the performance of internal electronic components.

5. Mechanical Manufacturing

Subtractive manufacturing is widely used in mechanical engineering, such as manufacturing parts for machine tools, precision instruments and industrial equipment. High-precision processing can improve the working efficiency and life of machinery.

In the field of mold manufacturing, subtractive processing is used to make injection molds, stamping molds, etc. High-precision mold manufacturing directly affects the quality of subsequent products.

7. Customization and small batch production

With the increase in personalized needs, subtractive manufacturing is also used for small batch production of customized products, which can respond quickly according to the specific needs of customers.

In short, subtractive manufacturing plays a key role in many industries with its high precision and high efficiency, promoting the continuous development and progress of manufacturing technology. With the emergence of new technologies, the application areas and technical levels of subtractive manufacturing will continue to expand to meet the ever-changing market needs.

Xuanmin provides a variety of metal and non-metal material processing services, including aluminum, stainless steel, titanium alloy, plastic, etc., which can meet the performance requirements of different products. Contact us to start your metal processing project.