In the metal manufacturing process, composite materials are increasingly valued because they combine the advantages of different materials, have excellent performance and a wide range of application potential. Composite materials are usually composed of two or more different materials, aiming to achieve better performance in structure.

1. Definition of composite materials

Composites are material systems composed of at least two components, at least one of which is a matrix (usually a polymer, metal or ceramic), and the other components are called reinforcing materials (usually fibers, particles or other forms of fillers). Through reasonable design and combination, the comprehensive performance of these materials is often better than that of individual materials.

2. Classification of composite materials

Classification by material type

Metal matrix composites (MMC)

Metal is used as the matrix material, and the reinforcement phase is usually ceramic particles or fibers. For example, aluminum-based composites and titanium-based composites are used to enhance the properties of metals, such as strength and wear resistance.

Polymer matrix composites (PMC)

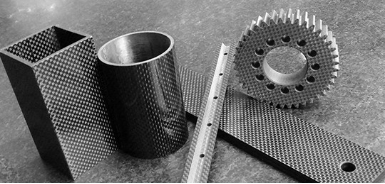

Polymer is used as the matrix, and the reinforcement material is generally fiber, such as glass fiber or carbon fiber, which is widely used in lightweight structures.

Ceramic matrix composites (CMC)

Ceramic is used as the matrix, and metal fibers or ceramic particles are added to improve its toughness and heat resistance.

Classification by structure

Layered composites: Made of multiple layers of different materials, using the properties of different materials to meet requirements.

Particle-reinforced composites: Reinforced particles are dispersed in the matrix to improve performance.

Fiber-reinforced composites: Long fibers are added to the matrix to increase strength and stiffness.

3. Advantages of composite materials

High strength and light weight

Composites often have a higher strength-to-weight ratio than traditional metals, making them suitable for applications in aerospace and automotive fields.

Excellent corrosion resistance

Compared to pure metals, composites are superior in chemical and environmental corrosion.

Good fatigue performance

Composites show better fatigue performance under repeated loads.

Design flexibility

The proportion and shape of different components can be adjusted to meet the needs of specific applications.

4. Application of composite materials

Aerospace

The requirements of light weight and high strength make composite materials widely used in aircraft and spacecraft.

Automotive industry

Used to improve fuel efficiency and reduce emissions, and enhance vehicle safety and performance.

Sports equipment

Such as high-performance bicycles, snowboards, etc., use composite materials to reduce weight and improve performance.

Construction engineering

Composites are used in some building components and infrastructure to improve durability.

5. Challenges in the manufacturing process

Although composite materials have many advantages, they still face certain challenges in the metal manufacturing process, such as:

Process complexity

The manufacturing process of composite materials involves the combination of multiple materials, and the process design is relatively complex.

Cost issues

Compared with traditional materials, the manufacturing cost of composite materials may be higher, which limits their wide application in certain fields.

Processing difficulty

The processing and molding of composite materials require special equipment and technology, and the tools may be worn during cutting.

Composite materials in metal manufacturing combine the advantages of different materials to achieve excellent performance and a wide range of application prospects. Although there are some challenges in manufacturing process and cost, with the development of materials science, the application of composite materials will continue to expand, providing new possibilities for innovation in various industries.

Xuanmin has an experienced technical team with deep expertise and rich project experience, and is able to provide customers with high-quality services and solutions. We have established long-term and solid cooperative relationships with suppliers and customers, focusing on transparent and honest business cooperation to create greater value for customers. Choosing our company means choosing a trustworthy partner. We will do our utmost to meet your needs, jointly promote project success, and help you develop in the industry.