Face milling is a traditional cutting process widely used in the field of metal processing. With the advancement of science and technology and changes in production needs, its technology continues to develop and evolve, becoming an important part of modern manufacturing. As an effective material removal method, face milling is not only used to process flat surfaces, but also suitable for processing complex surfaces such as specific shapes, contours and grooves. Therefore, its flexibility and versatility make it widely used in various industries.

Concept of face milling

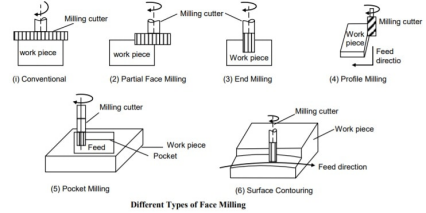

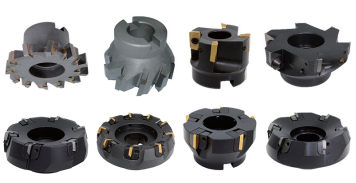

Face milling is a common metal cutting method, which is mainly used to process planes (such as vertical or horizontal surfaces), grooves, contours, etc. The main tool for face milling is a milling cutter, which usually consists of multiple cutting edges and can cut on the surface of the workpiece.

Working Principle of Face Milling

During the face milling process, the rotational motion of the tool and the feed motion of the workpiece are combined, and the cutting edge of the tool contacts the surface of the workpiece, thereby removing excess material and forming the desired surface shape.

Features of face milling

High cutting efficiency

Face milling can remove a large amount of material in a short time and is suitable for mass production.

Versatility

Face milling can complete a variety of processing tasks, including processing planes, grooves, contours and bevels, etc., with strong adaptability.

Good surface quality

Face milling can obtain a good surface finish and is suitable for processing parts with high requirements for surface quality.

Long tool life

Due to the use of milling cutters made of high hardness and high wear-resistant materials, the tool life of face milling is relatively long, reducing material costs.

High precision can be achieved

By controlling the feed speed and cutting parameters, face milling can achieve high processing accuracy and is suitable for the processing of precision parts.

Application areas of face milling

1. Manufacturing

Machinery parts processing: In machinery manufacturing, face milling is often used to process the planes of various mechanical parts, such as brackets, bases and covers.

Mold manufacturing: Used to make plastic molds, stamping molds and hot milling molds, etc., to ensure the accuracy and flatness of the molds.

2. Automobile industry

Engine parts: Face milling can be used to process engine cylinder heads, oil pans and other parts that are directly related to the accuracy of engine operation.

Chassis parts: For various components of the chassis, such as brackets and connecting parts of the suspension system, face milling can provide the required shape and surface quality.

3. Aerospace

Aerospace parts processing: In aircraft parts, such as wing structures and engine components, face milling is used to ensure accuracy and strength while reducing weight.

High-precision parts: The aerospace field has extremely high requirements for parts, and face milling technology can meet these high-precision requirements.

4. Electronics industry

Radiators and housings: Face milling is used to process radiators and housings of electronic products to ensure their proper shape and good heat dissipation performance.

Circuit board bracket: used to manufacture circuit board brackets and connecting parts to ensure the stability of electronic components.

5. Mold and tool industry

Tool and mold making: Face milling is used to make various types of cutting tools and molds to ensure their shape and accuracy.

Precision machining: used for the machining of high-precision, complex-shaped mold parts to improve the performance of tools.

6. Shipbuilding and marine engineering

Hull and structural parts machining: In the shipbuilding process, face milling is used to machine the hull and other structural parts to improve the stability and durability of the structure.

Marine equipment manufacturing: Face milling is suitable for the manufacture of marine structures such as platform brackets and anchors.

7. Heavy machinery

Machining of large mechanical parts: used for components of heavy equipment and machinery, such as excavators, bulldozers and transportation equipment parts.

Machining of structural parts: Face milling is also used for the machining of frames and bases of large equipment to ensure strength and stability.

8. Construction industry

Prefabricated component processing: In the construction industry, face milling can be used to process metal connectors for prefabricated concrete components.

Structural parts manufacturing: used for the manufacture of supports and connectors for steel structure buildings

The flexibility and adaptability of face milling make it an important manufacturing process for many industrial applications. As an important metal cutting processing technology, face milling is widely used in modern production and manufacturing due to its high efficiency, versatility and good surface quality. Whether in mechanical processing, automobile manufacturing, aerospace or other industries, face milling plays an important role. These characteristics make face milling maintain an important position in modern manufacturing.