Brushing is a common coating technology and is widely used in surface treatment of metal, wood, plastic and other materials. Brushing can effectively improve the appearance quality and corrosion resistance of the product and extend its service life. However, a good brushing effect depends not only on the performance of the coating itself, but also on the previous surface treatment.

Purpose of brushing surface treatment

Improve coating adhesion

Good surface treatment can enhance the adhesion between the coating and the substrate and prevent the coating from peeling or falling off.

Improve appearance

Through cleaning and treatment, impurities and defects can be removed, making the coating surface smoother and more beautiful.

Prevent corrosion

For metal materials, proper surface treatment can form a protective layer and reduce the risk of oxidation and corrosion.

Enhance durability

Through reasonable surface treatment, the wear resistance and durability of the coating can be effectively improved, extending the service life of the product.

Common steps for brushing surface treatment

1. Cleaning

Remove dirt: Use detergent, solvent or water to clean grease, dust and other impurities on the surface of the substrate.

Drying: Make sure the surface is dry to avoid affecting the adhesion of the coating.

2. Sanding

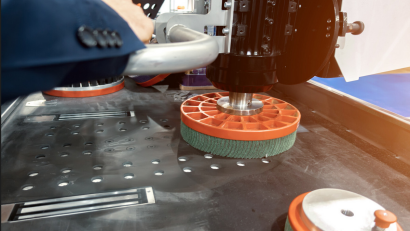

Use sandpaper or sanding tools to sand the surface to eliminate surface unevenness and flaws, increase roughness, and make the coating easier to adhere.

Choose the appropriate sandpaper coarseness according to the material type and ensure uniform sanding.

3. Rust prevention treatment (for metal)

For metal surfaces, rust inhibitors or primers can be used for treatment to form a protective film to further enhance corrosion resistance.

4. Primer brushing

In some cases, brushing primer can provide better adhesion and coverage, especially for smooth and difficult-to-adhere surfaces.

5. Strict inspection

Before brushing, carefully inspect the treated surface to ensure that there are no residual impurities and unevenness.

Common precautions for brushing surface treatment

Choose the right cleaner

Choose the right cleaner for different materials and avoid using chemicals that are corrosive to the materials.

Moderate grinding

Do not over-grind to avoid damaging the substrate or affecting the subsequent coating effect.

Drying time

Make sure the surface is completely dry before brushing to avoid moisture affecting the coating effect.

Environmental control

Carry out surface treatment and brushing in a well-ventilated, suitable temperature and humidity environment to ensure the leveling and curing effect of the coating.

Safety protection

When using chemical cleaners and coatings, wear appropriate personal protective equipment, such as gloves and masks, to ensure safe operation.

Brushing surface treatment plays a vital role in the painting process. Through scientific and reasonable cleaning, grinding and primer application, the adhesion, finish and durability of the coating can be significantly improved, ensuring that the final painting effect meets the expected standards. With the continuous advancement of technology and the development of materials, mastering and optimizing the brushing surface treatment process will bring higher quality assurance and market competitiveness to the majority of manufacturers.

Xuanmin always takes customers as the center and attaches great importance to communication and cooperation with customers. During the entire surface treatment cooperation process, we will provide professional pre-sales and after-sales support to ensure that customers can get the best experience when using our products.