With the rapid development of modern industry, metal extrusion technology has played a role in the application of lightweight, high strength and excellent precision parts. Whether in the aerospace and automotive industries, as well as in construction and electronic equipment, metal extrusion has demonstrated its irreplaceable value, providing excellent technical support for innovative product design and efficient production.

An overview of metal extrusion

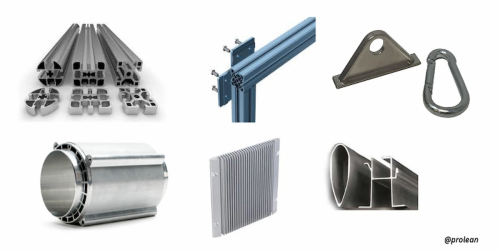

Metal extrusion is an important metal forming process, by pressing metal materials through the mold under high pressure conditions to form parts with a specific extrusion surface shape. This process can effectively utilize the material characteristics to produce parts with high strength, light weight and complex structure.

Process characteristics of metal extrusion

High plastic deformation

In the process of metal extrusion, the material is subjected to strong pressure, flows under the condition of plastic deformation, and forms a predetermined shape through the mold.

Multiple process methods

Direct extrusion: The metal material is extruded through the die in the direction of pressure.

Extrusion pressure: The mold moves with the pressure, so the direct extrusion pressure is less.

Cold extrusion and hot extrusion: according to the processing temperature is divided into two, cold extrusion is suitable for delicate products, hot extrusion is suitable for complex shape parts.

High material utilization rate

Extrusion process can minimize material waste, especially suitable for the processing of expensive metals (such as aluminum alloy, titanium alloy, etc.).

productivity

The process is fast, and a large number of parts can be continuously produced to meet the needs of industrial scale.

Precautions for metal extrusion

Mold design

Mold design is the key, affecting the quality of the finished product, shape accuracy and production efficiency.

Process temperature control

Select the right extrusion temperature according to the type of metal to prevent cracking or deformation of the material.

Material selection

The extrusion material needs to have good ductility to ensure a smooth process.

Equipment maintenance

Extruders and molds need regular maintenance to avoid product defects caused by equipment problems.

Product post-treatment

Surface treatment of the product (e.g. anodizing, electroplating, etc.) as required to enhance durability and aesthetics.

Application of metal extrusion

Automobile Industry

Lightweight components: Used for frame, battery housing, anti-collision beams and other structural components to help reduce the weight of the vehicle.

Cooling systems: Production of heat exchangers, radiator tubes and cooling fins.

Spaceflight

Structural components: Manufacture of aircraft frames, wing spars and fuel lines with high strength-to-weight ratios.

Precision Parts: Integrated, high-precision components for critical aerospace systems.

Build

Building materials: Make durable and corrosion-resistant materials for Windows, doors and curtain walls.

Decorative components: Allow the use of complex cross sections to achieve an aesthetically pleasing architectural design.

Electronic Product

Radiators: Produce efficient thermal management systems for electronic equipment.

Equipment housings: Manufacture lightweight, robust housings for phones, computers, and communication equipment.

Renewable Energy

Solar and wind structures: Build sturdy, weather-resistant stands for solar panels and wind turbines.

Cooling pipes: for energy storage and power generation systems.

Medical Equipment

Manufacture durable and precise frames and parts for medical devices and support systems.

The high efficiency, high strength and flexible design of metal extrusion process enjoy an important position in modern manufacturing industry. Through scientific process design and precision control, extrusion process can not only realize the efficient use of materials, but also produce high-quality parts to meet the needs of diversified products, providing important support for industrial innovation and sustainable development.

At Xuanmin, we offer customized services and metalworking with a focus on quality. Contact us today and let us make your project a reality.