Titanium is a metal material with excellent performance. Due to its unique physical and chemical properties, it has been widely used in many industries. Titanium has low density, high strength, excellent corrosion resistance, and good biocompatibility, which makes it occupy an important position in aerospace, chemical, medical, electronics, and automotive fields. With the continuous advancement of science and technology and the continuous increase in material demand, the application scope of titanium materials has gradually expanded, especially in high-end industrial fields, the advantages of titanium alloys have become more prominent.

Sources of titanium materials

Titanium is a relatively abundant metallic element in the earth's crust, widely distributed, and mainly found in titanium ores. The main sources of titanium ore are ilmenite and rutile. The extraction of titanium mainly depends on separating titanium metal from these ores.

Excellent performance characteristics of titanium

1. Strong corrosion resistance

One of the biggest advantages of titanium is its excellent corrosion resistance. Titanium has very high corrosion resistance in environments such as moisture, seawater, acid and alkali, and can even maintain stable physical properties under strong acidic or alkaline conditions. This makes titanium very suitable for electronic devices in harsh environments, especially electronic components that require long-term reliability and durability.

2. High strength, low density

Titanium has a high strength-to-weight ratio. Its specific strength (that is, the ratio of strength to density) is higher than that of steel, while its density is lower than that of steel, which means that titanium can provide sufficient strength without adding too much weight. Titanium is an ideal material for electronic parts that require lightweight and high strength (such as laptop cases, mobile phone cases, tablets, etc.).

3. Biocompatibility

Titanium has excellent biocompatibility and is widely used in medical devices such as artificial joints, dental implants, etc. Titanium's compatibility with human tissue has also made it used in some electronic devices (such as wearable devices, health monitoring devices, etc.), especially in parts that come into contact with the skin or human body.

4. Good electrical and thermal conductivity

Although titanium's electrical and thermal conductivity are not as good as copper or aluminum, it can still maintain good performance under high temperature conditions. Titanium can withstand high temperatures and work stably without losing its structural strength. For some high-temperature electronic devices and high-performance computing devices (such as laptops, mobile phones, etc.), titanium can be used as part of the heat dissipation material to improve the thermal stability of electronic components.

5. High temperature resistance

Titanium has excellent high temperature resistance. It can work stably in high temperature environments, especially with high-power electronic devices

(such as avionics, satellite communication equipment, etc.) related applications. Titanium can not only withstand high temperature changes, but also maintain the stability of the material to avoid the impact of thermal expansion or deformation on electronic equipment.

6. Good processability

Although titanium has a high hardness, it has good processability, especially with the support of modern processing technology. Titanium can be used to make complex electronic parts through precision casting, CNC processing, laser cutting, etc. to meet the requirements of precision design. In many electronic applications, the processability of titanium makes it an ideal material.

7. Electromagnetic shielding properties

Titanium itself has a certain electromagnetic shielding ability, which can effectively suppress external electromagnetic interference (EMI) and radiation and maintain the stability of electronic components inside the equipment. This makes titanium an ideal material in some high-precision electronic equipment (such as communication equipment, satellite equipment, etc.) to help reduce electromagnetic interference.

8. Environmental protection and sustainability

Titanium is a highly recyclable material, and the waste generated during its production process can be recycled and reused. In addition, titanium can be recycled and processed into other products after its service life, which meets the requirements of sustainable development. As modern electronic products pay more and more attention to environmental protection, the application of titanium as an environmentally friendly material in the electronics industry is gradually increasing.

Application of Titanium Materials

Titanium is widely used in many industries, especially in aerospace, chemical, medical and electronic fields, due to its excellent properties such as high strength, low density, strong corrosion resistance and good biocompatibility.

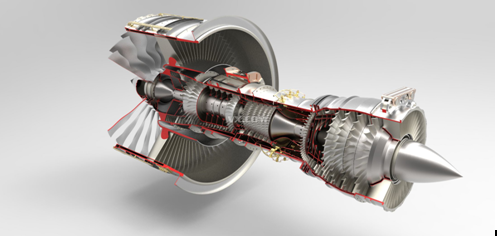

1. Aerospace

Aircraft structural components: such as fuselage frames, engine components, wings and control panels.

Rockets and spacecraft: Titanium has important applications in rocket engines, missiles, satellites, spacecraft and other spacecraft, and can withstand high temperatures and extreme environments.

2. Chemical and petroleum industries

Reactors and pipelines: Titanium can resist corrosion from strong acids, strong alkalis and seawater, and is often used in reactors, pipelines, heat exchangers and other equipment in chemical plants.

Marine engineering: In marine environments, titanium can resist corrosion from seawater and is widely used in offshore platforms, ships and marine exploration equipment.

3. Medical field

Artificial joints: Titanium is used to make artificial joints such as knee joints and hip joints because of its high strength and compatibility with human bones.

Dental implants: Titanium root implants and titanium alloy tooth restoration materials are widely used in dentistry because of their strong bonding with bone tissue.

Surgical instruments: Titanium is also used in various surgical tools and equipment, such as scalpels, bone screws, and skeleton supports.

4. Electronics and Electrical

Electronic product housings: such as mobile phones, laptops, and tablets, because of their light weight and high strength.

Electronic components: Titanium's high temperature stability and corrosion resistance make it an ideal material for certain high-temperature electronic components and battery electrodes.

Electromagnetic shielding: Titanium alloys can be used as electromagnetic shielding materials for high-end electronic devices to protect internal circuits from external interference.

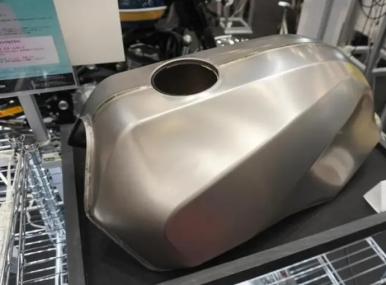

5. Automotive industry

High-performance automobiles: Titanium is used in engine components, exhaust systems, etc. of high-end sports cars because of its light weight and high temperature resistance.

Racing cars and motorcycles: The high strength and low weight of titanium alloys make them ideal for racing cars and high-performance motorcycles.

6. Sports equipment

Golf clubs, tennis rackets, bicycle frames: Titanium alloy’s light weight and high strength make it an ideal material for these equipment, which can improve sports performance and service life.

7. Wearable devices

Watches and jewelry: Titanium watches, earrings, necklaces, etc. are becoming the first choice for fashion because of their durability and lightness.

Smart device housing: Titanium is used in the housing of smart watches, fitness trackers and other devices, which is both beautiful and durable.

The high cost and complex processing of titanium materials also limit their widespread application in some fields. Therefore, in recent years, researchers have conducted a lot of research on the extraction process, processing technology and performance optimization of titanium materials, aiming to reduce the production cost of titanium materials and improve their application performance in industry and daily life. Through in-depth research on the source, extraction process and application fields of titanium materials, we can better understand the unique properties of titanium and provide technical support for its application in more fields.

Xuanmin's experts understand the complexity of titanium alloy processing, and we are ready to help you with your project. We combine advanced tools with first-class expertise to provide titanium processing services that exceed your expectations. Contact us today to discuss your project further.