Springs are important components widely used in various mechanical and electronic devices. There are many types of springs according to their shapes, functions and materials, and each type of spring plays a unique role in different application scenarios.

Definition of spring

A spring is a mechanical element that uses its own elastic deformation to store and release mechanical energy. It is often used to withstand external forces or adjust the state of a system. It can undergo elastic deformation when subjected to external forces and return to its original shape after the external force is removed. The main function of a spring is to provide thrust, tension or torque through its elastic properties, thereby adjusting the state of the system, controlling the balance of motion or stabilizing forces.

Characteristics of springs

Elasticity

Springs have a certain elasticity, which means they can deform under external forces and return to their original shape after the external forces are removed. This property allows springs to effectively store and release energy.

Energy storage

Springs store energy by deforming, and when the external forces are removed, the springs release the stored energy. This is one of the core principles that allow springs to be used in many devices, such as car suspension systems, clock springs, etc.

Stress-strain relationship

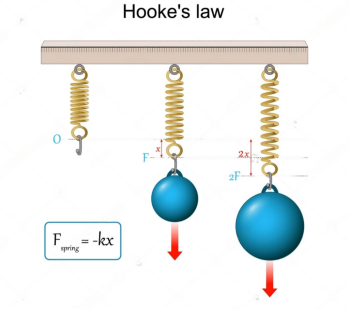

Springs follow a certain stress-strain relationship during deformation, especially for small deformations, which conforms to Hooke's law

Directionality

Springs can withstand forces in different directions, such as tension, compression, torsion, etc. Different types of springs have different designs depending on the direction of the external force to meet different application requirements.

Structural diversity

Springs have a variety of shapes and structures, such as spiral, wave, flat, etc. Depending on the required mechanical properties, the shape, size, material and other parameters of the spring will vary. Choosing the right design can improve work efficiency and service life.

Load capacity

The load capacity of a spring is closely related to its material, size and structural design. Larger springs can withstand greater loads and are suitable for mechanical systems that withstand greater forces.

Limited working range

The working range of a spring is limited by the elastic limit of its material. After exceeding the elastic limit, the spring may undergo permanent deformation or fatigue damage, resulting in spring failure. Therefore, its mechanical properties and application environment need to be considered during design.

Fatigue resistance

Springs are usually required to withstand repeated loads, so their fatigue resistance is very important. High-quality springs use materials with a higher fatigue limit and are optimized for a longer service life.

Damping characteristics

Some types of springs (such as hydraulic springs, gas springs, etc.) have strong damping characteristics, which can effectively reduce vibration, impact and noise, and are widely used in the automotive, aerospace and other fields.

Several common types of springs and their applications

1. Compression Spring

Structure: usually spiral, bear compression force, the outer diameter and inner diameter of the spring and the wire diameter have certain requirements.

Application:

Automotive industry: suspension system, shock absorber.

Household appliances: door closing device of washing machine and refrigerator.

Industrial equipment: pressure regulator, pneumatic device.

2. Tension Spring

Structure: Usually also spiral, but with hooks at both ends, mainly used to withstand tension.

Application:

Door and window equipment: used for curtain pulling devices, door buffer devices.

Agricultural machinery: such as the tensioning device in the strapping machine.

Sports equipment: such as the tensioning system in the spring trampoline.

3. Torsion Spring

Structure: Spiral-shaped, able to withstand torsion, and store energy through twisting deformation.

Application:

Door and window system: used for rolling doors, spring doors, etc.

Automotive parts: adjustment device for car seats.

Toys: such as clockwork toys and rotating devices.

4. Hydraulic Spring

Structure: It combines the principles of liquid pressure and spring, and is used to bear larger loads.

Application:

Automobile suspension system: hydraulic shock absorber.

Engineering machinery: shock absorption and load-bearing devices such as excavators and cranes.

Aircraft system: used in shock absorption systems to reduce the impact of aircraft landing.

5. Constant Force Spring

Structure: Usually a thin steel strip or thin metal sheet that provides a constant force by bending or stretching.

Application:

Clockwork: such as clock springs.

Medical equipment: such as bed adjustment devices.

Automatic equipment: automatic paper winding machines, automatic wire pulling devices.

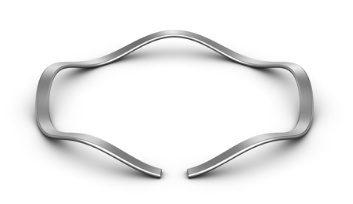

6. Wave Spring

Structure: Designed in a wave shape, it can be compressed to save space and is often used in smaller spaces.

Application:

Precision instruments: such as optical equipment and precision machinery.

Electronic equipment: used as pressure devices in batteries, capacitors or other small devices.

7. Gas Spring

Structure: A spring containing compressed gas, which can withstand external forces and generate reaction forces, and has a good damping effect.

Application:

Automotive industry: used for adjusting car trunks and seats.

Furniture industry: such as the height adjustment system of office chairs.

Aerospace: The support system of aircraft seats.

8. Magnetic Spring

Structure: Uses magnetic field to realize the function of spring.

Application:

Precision instruments: such as support in magnetic levitation system.

Shock absorber: Magnetic levitation system used to reduce vibration and impact.

9. Conical Spring

Structure: Spring with a conical shape, usually used in small precision equipment, can withstand large loads and save space.

Application:

Precision instruments: such as sensors, instrumentation equipment.

Small machinery: used for tightening and adjusting positions.

As a basic and important mechanical element, springs have been widely used in all walks of life due to their unique elasticity and energy storage characteristics. Whether in automobiles, aerospace, precision instruments, home appliances, or in modern industrial production, springs play a vital role. With the advancement of science and technology, the design, materials, and application scenarios of springs are also constantly innovating and developing.

In order to ensure that springs can perform at their best in specific applications, it is crucial to correctly select and design springs. This requires comprehensive consideration of factors such as mechanical properties, working environment, load requirements, and fatigue life. With the emergence of new materials and new technologies, the functions and applications of springs will become more diversified, and will surely be innovated and deepened in more fields.