Stamping parts are metal parts made by stamping process, which are widely used in many fields such as automobiles, home appliances, electronics, machinery, etc. Stamping parts can be classified into many categories according to different stamping processes, shapes, applications and materials.

Classification by process

Stamping parts can usually be divided into the following categories according to the specific process used in their production process:

Simple stamping parts: These stamping parts have a relatively simple shape and can usually be processed by only one stamping. For example, ordinary gaskets, thin-walled metal sheets, etc.

Deep stamping parts: Also called deep drawing parts, they are made by drawing metal sheets into a deeper shape through the deep drawing process. They are usually used to manufacture deeper workpieces such as automobile shells, containers, and thin cylinders. Deep stamping parts generally require multiple stamping processes.

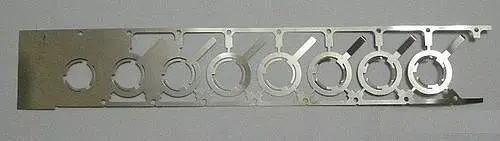

Compound stamping parts: They are made by combining multiple stamping processes (such as punching, shearing, bending, stretching, etc.), and the process is more complicated. Usually used for parts with complex shapes or multiple processes.

Precision stamping parts: These stamping parts require very high processing accuracy and usually use high-precision molds. Precision stamping parts are widely used in electronics, communications and other fields.

Classification by shape

Stamping parts can be divided into the following categories according to their shapes:

Flat stamping parts: parts with flat or slightly curved shapes, relatively simple, such as thin plates, gaskets, etc.

Three-dimensional stamping parts: including stamping parts with three-dimensional or complex geometric shapes, such as car bodies, home appliance shells, oil storage tanks, etc.

Hollow stamping parts: parts with hollow structures formed by stamping, widely used in the automotive and home appliance industries. For example, automobile fuel tanks, pipes, etc.

Classification by application field

According to the specific use of stamping parts, they can be divided into different application categories:

Automobile stamping parts: The automotive industry has a wide demand for stamping parts, such as body, chassis, doors, bumpers and other key parts.

Home appliance stamping parts: Stamping parts in the home appliance industry are widely used, mainly including the shells, brackets and other parts of refrigerators, washing machines, electric fans, air conditioners and other home appliances.

Electronic stamping parts: Such as the shells, connectors, screen brackets, etc. of electronic products, such stamping parts usually require higher precision.

Industrial stamping parts: Including various mechanical parts, tools, equipment parts, etc., these parts often need to bear large loads, such as mechanical brackets, frames, etc.

Classification by material

According to the type of material used, stamping parts can be divided into the following categories:

Steel stamping parts: Steel is the most common stamping material, suitable for stamping manufacturing of various structural parts, especially widely used in the automotive and mechanical industries.

Stainless steel stamping parts: Stainless steel materials have excellent corrosion resistance and are suitable for some special industrial environments, such as chemical equipment, food industry, etc.

Aluminum alloy stamping parts: Aluminum alloys are widely used in the automotive and electronics industries due to their lightweight characteristics and excellent forming properties.

Copper alloy stamping parts: Copper and copper alloy materials have good conductivity and corrosion resistance, and are often used in electronic products and electrical equipment.

Classification by function of stamping parts

According to the main function of stamping parts, they can be classified as follows:

Load-bearing stamping parts: These stamping parts are mainly used to bear mechanical loads, such as frames, brackets, etc.

Decorative stamping parts: This type of stamping parts is mainly used for appearance decoration, usually requiring beautiful appearance and good surface treatment technology, and is used in home appliances, automobiles, consumer electronics and other fields.

Connection stamping parts: Mainly used for the connection and fixation of parts, such as nuts, washers, screws, etc.

Classification by the complexity of stamping process

Single-process stamping parts: This type of stamping parts is completed by one die stamping, with a simple process, suitable for parts with simple shapes and low production batches.

Multi-process stamping parts: This type of stamping parts needs to be completed through multiple die processing steps, and is usually used for parts with complex shapes and large production batches.

Different categories of stamping parts have their own characteristics and application scope. When choosing stamping parts, you need to consider factors such as product shape, purpose, precision requirements, material, and production batch. Mastering these classifications will help you choose the most suitable process and manufacturer to meet specific production needs.