As the global manufacturing industry continues to develop towards precision, high efficiency and automation, the processing industry continues to have exciting new technological innovations and market opportunities. In recent years, CNC machine tool technology, automated processing equipment and advanced material processing technology have continuously promoted the transformation and upgrading of the manufacturing industry, especially in high-precision industries such as automobiles, aerospace, medical, and electronics, the application of machining technology is playing an increasingly important role.

Machining definition

Machining refers to a manufacturing method that uses various machine tools (such as lathes, milling machines, grinders, drilling machines, etc.) to cut and process metal or non-metal materials to change the shape, size and surface quality of the workpiece. It is one of the most basic processing methods in the manufacturing industry and is widely used in many fields such as machinery manufacturing, automobiles, aerospace, electronics, and energy.

Classification of machining

Turning is a process of cutting workpieces using a lathe through a rotating workpiece and a fixed tool. It is often used to process workpieces with rotationally symmetrical shapes such as shafts, discs, and cones. The processing content that can be completed by turning includes outer circles, inner holes, threads, end faces, steps, tapers, etc.

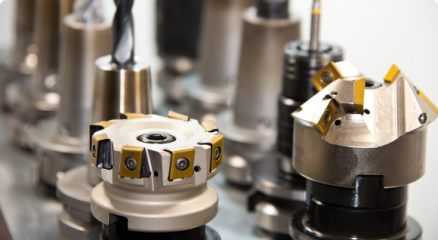

Milling is a process of cutting workpieces using a milling machine and a rotating cutting tool. Milling can be used to process various shapes such as planes, curved surfaces, grooves, gears, etc. Milling machines can be horizontal or vertical and are suitable for more complex surface processing.

Drilling

Drilling is the processing of holes in workpieces using a drilling machine and a drill bit, including drilling, reaming, and boring. Drilling is often used to process holes in metal or plastic materials and has high precision requirements.

Grinding

Grinding is the cutting of workpieces using a grinder and a grinding wheel. It is often used to improve the surface accuracy and finish of the workpiece, or to trim the processed parts. Grinding can be applied to many fields such as planes, outer circles, and inner holes.

Slotting

Slotting is a cutting process using a slotting machine, which is suitable for machining some complex contours and special-shaped holes. There are horizontal and vertical slotting machines, which are often used for mass production and precision machining.

Electrodischarge machining (EDM)

Electrodischarge machining is a process that generates electric sparks between the electrode and the workpiece to burn away the surface material of the workpiece. This machining method is particularly suitable for precision machining of hard materials and complex shapes.

Common machining processes

Cutting

including turning, milling, drilling, grinding, etc., which is a process of removing excess material to achieve the required shape and size.

Precision machining

using high-precision machine tools and tools, such as CNC machining (CNC), electrical discharge machining (EDM), laser cutting, etc., can achieve higher machining accuracy and surface quality.

Forming

mainly refers to processing metal or other materials into a specific shape through a mold, such as stamping, casting, extrusion, etc.

Advantages of machining

High precision and high quality

Machining, especially CNC machining (CNC), can meet the processing requirements of complex shapes while maintaining high precision, ensuring the accuracy of the size, surface finish and shape of the parts.

Strong adaptability

Machining is suitable for a variety of materials (such as steel, aluminum alloy, copper, plastic, etc.), which can not only process complex geometric shapes, but also meet the processing needs of workpieces of different materials.

Mass production capacity

Through CNC technology and automated processing equipment, machining can achieve efficient mass production and ensure the consistency and stability of processing.

Versatility

Different machine tools can perform various processing tasks, such as turning, milling, drilling, grinding, etc., and can handle different workpiece shapes, sizes and requirements.

Customized production

Machining supports customized product production, especially in the manufacture of complex and precision parts, and can perform highly personalized processing according to customer needs.

Application fields of machining

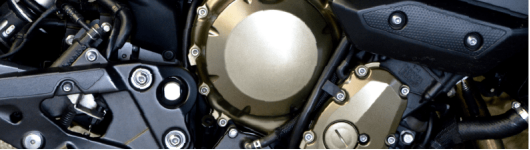

In automobile production, machining is widely used in the manufacture of engine parts, body structural parts, transmission system parts, precision parts, etc. High-precision machining ensures the performance and durability of automobile parts.

Aerospace

The aerospace industry requires extremely high machining accuracy and stability. Machining is widely used in the processing of engine parts, structural parts and high-strength materials. Especially under high temperature and ultra-high precision requirements, machining technology is indispensable.

Electronic products

The electronics industry needs to process a large number of precision parts, such as mobile phone casings, computer motherboards, connectors, etc. Machining technology can provide high-precision and meticulous surface processing to meet the high standards of electronic products for dimensional accuracy and appearance.

Mold manufacturing is an important application field of machining technology. Molds for casting, injection molding, stamping and other processes are produced through precision machining technology. The quality of the mold directly affects production efficiency and product quality.

Many high-precision parts in medical devices (such as surgical tools, implants, medical instrument components, etc.) also rely on machining technology. High precision and high reliability are key requirements for medical device production.

Energy and Heavy Industry

In energy industries such as oil, natural gas, wind power, nuclear energy, and heavy industries such as steel and metallurgy, machining technology is used to produce various parts made of high-strength and high-corrosion-resistant materials, such as pump bodies, valves, bearings, etc.

Challenges of machining

Precision and tolerance control

Although modern machine tools are becoming more and more accurate, it is still a challenge to accurately control each processing link in complex machining tasks, especially for high-precision products and parts with tight tolerance requirements.

Material properties

The machining properties of different materials vary greatly. For example, metal materials with higher hardness (such as titanium alloys, hardened steel, etc.) require special tools and processes when machining, which increases the difficulty and cost of machining.

Machining costs

High-precision and high-complexity machining requirements usually require advanced machine tools and equipment, and the machining cycle is long, and material waste is also large, which leads to increased costs.

High technical requirements

High-end machining requires operators to have a high level of technical skills, especially when using CNC machine tools, operators need to master complex programming techniques and operating skills.

Equipment and tool wear

During the machining process, tools, machine tools and equipment will experience wear, which affects the machining accuracy and quality, so regular maintenance and tool replacement are essential.

The innovation of machining technology not only promotes the development of manufacturing industry, but also brings new opportunities to various industries. Under the background of globalization and automation, the machining industry will surely have a more prosperous development space in the future.

Machining is an indispensable process in industrial production. It is widely used in various industries with its advantages of high precision, high stability and strong applicability. Choose Xuanmin for machining cooperation and make satisfactory metal processing parts. Contact us to start production!