With the popularization of CNC technology and intelligent production lines, the turned parts manufacturing industry faces huge opportunities. The demand for turned parts in automobile manufacturing continues to grow, especially in core components such as engines, gearboxes and brake systems. Precision turning processing technology has become a key factor in ensuring the performance and reliability of parts. Industry insiders predict that in the next few years, with the further popularization of intelligent turning technology, the production of turned parts will be more efficient and precise, providing the automotive industry with more high-quality, low-cost parts.

Overview of Turned Parts

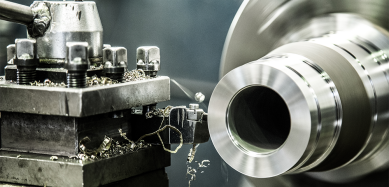

Turned parts are parts manufactured by lathes, which mainly use turning tools to cut rotating workpieces, and can produce complex geometric shapes such as circles, shafts, internal and external threads, round holes, planes, etc. of different shapes and sizes. The turning process has the advantages of high precision, high efficiency and smooth surface, and is suitable for the processing of various metal and non-metal materials, such as aluminum, steel, copper, plastic, etc.

Characteristics of turned parts

High precision and dimensional stability

Turned parts have high machining accuracy and dimensional stability, which are suitable for strict precision assembly. Even after long-term use, parts can maintain high dimensional consistency.

Suitable for mass production

Turned parts have strong mass production capacity, especially with the support of CNC lathes, which can efficiently process a large number of standardized parts to meet the high demands of the automotive, machinery and other industries.

Reduce material waste

Turning processing usually uses cutting methods, unlike casting, forging and other processes that produce a large amount of material waste.

High strength and durability

Since turned parts usually use high-strength materials and have high machining accuracy, the produced parts have high durability and wear resistance, and are suitable for high-load and high-frequency use working environments.

Customizable

Turned parts can be customized according to customer needs to meet different shapes, sizes and functional requirements. This makes turning technology have important advantages in personalized customization, especially in the production of complex parts.

Factors affecting turned parts

During the machining process of turned parts, there are several important points to note, which directly affect the machining quality, efficiency and cost. The following are the key points to note in turning:

Tool selection and management

tool material, tool geometry, tool wear monitoring

Cutting parameter selection

cutting speed, feed speed and cutting depth, use of cutting fluid

Workpiece clamping and fixation

fixture selection, workpiece balance

Machining accuracy control

dimensional tolerance control, surface quality

Vibration control during machining

vibration source control, machine tool stability

Thermal deformation and temperature control

thermal expansion problems, cooling system

Process route and cost control

process design rationality, mass production and customization

Material selection and cutting properties

material hardness and cutting properties, material processing

Turned Parts Production Budget and Cost

The production budget of turned parts mainly includes the following aspects:

Raw material cost

The raw materials of turned parts are usually metals or alloys, and the price will vary with the type, hardness and special requirements of the material. For example, the prices of aluminum alloys, titanium alloys and steel will vary.

Processing costs

Turning processing usually includes multiple stages such as rough processing and fine processing, and requires the use of lathe equipment and various tools. The difficulty of processing, process requirements and the complexity of parts will affect the processing costs.

Equipment investment

The production of turned parts requires special lathe equipment, such as CNC lathes (CNC lathes), automatic lathes, etc., which have high procurement and maintenance costs.

Labor costs

Although the production of turned parts can be partially automated, operators are still required to perform equipment debugging, quality inspection and other tasks, and labor costs cannot be ignored.

Transportation and delivery

The delivery of turned parts usually requires packaging, transportation and logistics arrangements, especially for customized parts or mass production orders, and transportation costs will also affect the overall cost.

Budget calculation

The production cost of turned parts will vary depending on different processing requirements and part complexity. The following factors are usually considered in the budget:

Part material type, size and shape

Processing difficulty (whether special processes are involved, such as internal turning, threading, etc.)

Batch size

Production cycle (cost difference between mass production and small batch customization)

Application areas of turned parts

Automotive industry

turned parts are widely used in the production of automotive parts such as engines, gearboxes, wheels, bearings, hubs, brake discs, etc. Precision turning ensures the high performance and long life of these parts.

Aerospace

Aircraft engines, body structural parts, and spacecraft parts all need to be manufactured by turning to ensure high strength, light weight and precise assembly.

Mechanical manufacturing

turned parts are widely used in shafts, gears, couplings, propellers and other parts in various mechanical equipment to ensure the efficient operation of machinery and equipment.

Electronic industry

used to manufacture housings, connecting parts and precision mechanical devices in various electronic devices.

Medical devices

used to manufacture precision medical equipment parts, such as syringes, catheters, orthopedic instruments, etc.

Turning is a precision manufacturing process that requires control and optimization in many aspects. The accuracy and efficiency of turning can be effectively improved by selecting appropriate tools, cutting parameters, coolants, properly fixing the workpiece, ensuring the stability of the machine tool, and controlling factors such as vibration and thermal deformation that may occur during the processing. Appropriate processing technology design and process optimization can also help reduce production costs and improve production efficiency.

Finding the right processing is also a key step, which requires the engineer who estimates the price of the parts to have a high level of understanding of the processing of the parts. Xuanmin is good at turning parts processing. We have reasonable manufacturing costs and strict quality control standards. Contact us to start cooperation.