In the field of precision mechanical engineering, ball splines play a vital role. They are not only core transmission components, but also the key to the stability and efficiency of mechanical system operation.

Definition of ball spline

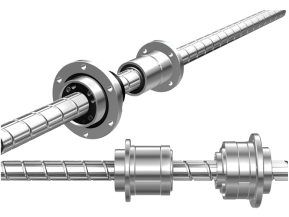

A ball spline is a transmission component in which a ball rolls linearly on a spline groove. It is a transmission structure that combines a spline and a rolling bearing, and is widely used in mechanical transmission systems that require high precision and low friction. It transmits torque and linear motion by rolling the ball in the spline groove, and has lower friction and higher efficiency than traditional splines.

The structure and working principle of ball splines

The basic structure of ball splines is similar to that of ordinary splines, but balls are embedded in the standard spline grooves. When the ball spline is in operation, the balls roll in the grooves of the splines, which can reduce friction and achieve a smoother, low-friction transmission compared to traditional spline connections.

External structure: Ball splines usually consist of a shaft with spline grooves and a matching sleeve with multiple balls inside. The external spline shaft is connected through the spline groove between the ball and the inner hole.

The role of the ball: The ball rolls in the spline groove, causing the contact surface between parts to become rolling contact, significantly reducing the friction coefficient and wear.

Transmission characteristics: Ball splines can transmit torque and linear motion at the same time, so they are often used in mechanical systems that require precise control of linear motion.

Advantages of ball splines

Low friction and high efficiency: ball splines reduce friction by rolling, making the transmission efficiency higher and suitable for applications with high precision requirements.

High load capacity and long life: Due to the action of the ball, the contact surface becomes a rolling contact, which reduces wear and improves durability and service life.

Smooth movement: Compared with traditional splines, ball splines provide smoother movement and are suitable for occasions that require fine motion control.

Application fields of ball splines

Ball splines are widely used in some equipment with high requirements for transmission accuracy, stability and life, such as:

Automation equipment: such as robotic arms and motion control systems, which require precise linear motion.

CNC machine tools: In CNC machine tools, ball splines are used for drive and positioning systems, which can reduce friction and improve efficiency.

Robotics: In the joints and drive parts of robots, ball splines are often used to achieve precise rotation and linear motion.

Ball spline products are widely used in different specific industries. Ball splines are frequently used in aerospace, shipbuilding, machinery production and other fields. For universal working scenarios, among the many parts used to achieve linear motion, the status of ball splines is becoming more and more important.