Metal production involves a variety of plastic processing methods, metal sheet material processing, and a variety of technology. Special features of Yuyu's high efficiency, equipment, construction, metal manufacturing, transportation, aviation, aerospace, electronics, construction and other areas.

Iron production established Iron metal production involves finger cutting, folding, bending, boning, etc., and the continuous processing of thin metal sheets, the final forming tool has a specific shape, size, size, and functional zero parts.

Metalworking definition

Iron metal production involves finger cutting, folding, bending, boning, etc., and the continuous processing of thin metal sheets, the final forming tool has a specific shape, size, size, and functional zero parts.

Main features of sheet metal manufacturing

Due to its diversity of processing methods and wide range of application areas, sheet metal manufacturing has the following significant characteristics:

High flexibility

Sheet metal manufacturing can process a variety of metal materials (such as steel plates, stainless steel, aluminum plates, copper plates, etc.) to meet the needs of different industries. Flexibly cope with the production of complex parts through processes such as shearing, stamping, bending, welding and surface treatment.

Cost advantage

The sheet metal manufacturing process is mature, the equipment is highly automated, and production efficiency is significantly improved. For simple parts, mold development costs are low, and they can be directly processed through standardized equipment, further saving costs.

High production precision

Modern equipment support: equipment such as laser cutting machines, CNC punching machines and CNC bending machines ensure the dimensional accuracy and consistency of parts processing. During the processing process, equipment or processes can be quickly adjusted to meet design needs.

Strong ability to process complex parts

Sheet metal processing can easily realize the forming of complex curved surfaces, special-shaped parts and multi-curvature parts; combined with welding, punching, flanging and other technologies, it can process multifunctional parts and improve the integrated functions of parts.

Lightweight materials

Sheet metal processing is mainly based on thin plates, with light structures, which adapts to the trend of lightweight design. It supports the processing of lightweight materials such as high-strength steel and aluminum alloy, and is widely used in automobiles, aviation and other fields.

Environmental protection and recyclability

The materials used in sheet metal manufacturing (such as steel, stainless steel and aluminum) have high recycling value and are in line with the concept of green manufacturing; by optimizing cutting methods and using environmentally friendly lubricants, processing waste and pollutant emissions can be reduced.

Common processes for sheet metal manufacturing

Shearing

Equipment: shearing machine, CNC shearing machine.

Function: Cut and strip metal sheets to obtain workpieces of required size.

Features: High cutting efficiency, suitable for relatively regular straight line cutting.

Equipment: punch press, CNC punch press.

Function: Form, punch, shear or bend the sheet through the die.

Features: Suitable for large-scale processing of complex shapes.

Equipment: bending machine, CNC bending machine.

Function: bending metal sheets into specific angles or shapes.

Features: can achieve high-precision forming and meet part design requirements.

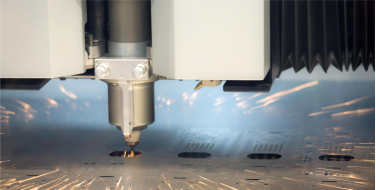

Equipment: Laser cutting machine.

Function: Cut or engrave the plate using a high-energy laser beam.

Features: High processing accuracy, suitable for complex curves and tiny features.

Methods: argon arc welding, laser welding, spot welding, etc.

Function: connect multiple sheet metal parts into an integral structure.

Features: high connection strength, can meet the use requirements of structural parts.

Methods: spraying, electroplating, oxidation, polishing, etc.

Function: Improve the corrosion resistance, aesthetics and durability of parts.

Features: Choose the appropriate processing method according to different application environments.

Application areas of sheet metal manufacturing

Body panels, chassis parts, dashboard housings, etc.

Sheet metal manufacturing provides lightweight and high-strength parts for automobiles.

Aerospace

Aircraft shells, cabin doors, seat brackets, etc.

Processing high-strength aluminum alloy and titanium alloy sheets to ensure light and durable structures.

Electronic and electrical equipment

Cabinets, housings, radiators, etc.

Sheet metal processing meets the needs of compact product structure, high precision and strong aesthetics.

Architecture and decoration

Metal curtain walls, ceilings, guardrails, etc.

Use materials such as stainless steel and aluminum plates to achieve structures that are both durable and decorative.

Home appliance industry

Refrigerator shells, washing machine frames, water heater panels, etc.

Sheet metal manufacturing helps home appliance products achieve unified functionality and appearance.

Industrial equipment

Machinery covers, brackets, sheet metal frames, etc.

Ensure equipment protection functions while providing beautiful designs.

Sheet metal manufacturing has become one of the important processes in modern industrial manufacturing due to its flexibility, high efficiency, low cost and wide adaptability. In the future, with the in-depth application of intelligent technology and new materials, sheet metal manufacturing will continue to develop in the direction of higher precision, higher efficiency and more environmental protection, providing more possibilities and innovation space for all walks of life.

It is important to work with a manufacturer that provides quality sheet metal processing services. Xuanmin has extensive manufacturing experience and provides high-quality sheet metal stamping and metal batch manufacturing services. Combining advanced technology and professional engineering personnel, we can always meet your various processing needs with high standards. Contact us today!