The automobile chassis is an important part of the vehicle structure, carrying the main components such as the body, power system and transmission system, and determines the safety, comfort and handling of the vehicle. In chassis design, stamping technology is widely used in the manufacture of chassis parts due to its high efficiency, precision and economy.

Core elements of automobile chassis design

Lightweighting

By optimizing chassis structure and material selection, weight can be reduced to improve fuel economy and driving performance.

Use high-strength steel, aluminum alloy or composite materials, and combine advanced stamping technology to form complex parts to achieve the goal of weight reduction.

Strength and rigidity

As a supporting and protective component of the vehicle body, the chassis needs sufficient strength and bending rigidity to ensure the safety and stability of the vehicle.

Vibration and noise control

The chassis needs to have a reasonable structure, combined with precise shape forming in stamping processing to reduce vibration and noise (NVH performance) during driving.

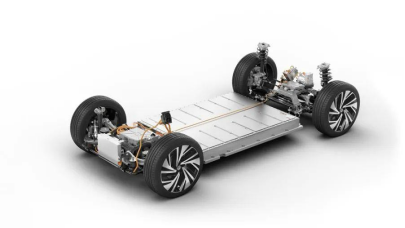

Space layout and multi-functional integration

Integrate the functions of multiple components in a limited space, such as suspension mounting points, transmission system support, etc. Stamping technology makes this possible through the forming of complex parts.

Durability and corrosion resistance

The chassis is exposed to harsh environments for a long time, and it is necessary to enhance corrosion resistance and service life through material selection and surface treatment (such as electroplating and spraying).

Advantages of stamping technology in automobile chassis

Efficient production

The stamping process has a high degree of automation, which is suitable for mass production and can effectively reduce manufacturing costs.

Lightweight design

Using high-strength steel or aluminum alloy, stamping complex shapes to achieve material weight reduction while ensuring structural strength, which is in line with the development trend of lightweight automobiles.

High precision and consistency

Through die forming technology, stamping parts have high dimensional accuracy and good batch consistency, meeting the high requirements of chassis components for assembly accuracy.

Complex shape processing

Stamping technology can process parts with complex cross-sections and multi-curvature shapes to meet the multi-functional needs of chassis components.

High material utilization rate

Stamping technology can optimize the layout of the sheet, reduce material waste, improve material utilization rate, and reduce production costs.

Stamping technology helps chassis design innovation

Hot stamping technology

Features: Use the plasticity of materials at high temperatures to form ultra-high-strength steel parts.

Application: For frame longitudinal beams and cross beams, hot stamping technology significantly improves the strength and collision resistance of parts, meeting the requirements of lightweight vehicles.

Multi-process integrated stamping

Features: Integrate multiple processes such as stamping, punching, trimming and bending into a set of molds to reduce the number of parts processing steps.

Application: Manufacture complex suspension brackets and steering system brackets to reduce processing time and assembly difficulty.

Forming simulation technology

Features: Use CAE simulation to optimize the stamping process, predict material flow and defect distribution, and avoid cracking or wrinkling.

Application: Used for mold design and process optimization of key parts such as frames and suspension systems.

Aluminum alloy stamping process

Features: Lightweight aluminum alloys with high processing difficulty can ensure the forming quality by adjusting stamping parameters.

Application: In the chassis of new energy vehicles, it is used for the manufacture of battery housings and chassis guards.

Application of stamping technology in automobile chassis

Stamping technology plays an important role in the manufacturing of chassis parts because it is suitable for mass production and has high processing efficiency.

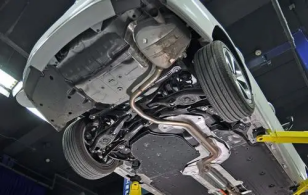

Longitudinal beams and cross beams: bear the weight of the vehicle body and the power system, and the U-shaped or H-shaped sections formed by stamping can improve the structural strength and rigidity.

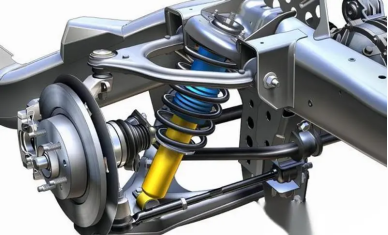

Suspension bracket: used to connect the suspension system and the frame, and complex geometric shapes are formed in one step by stamping technology.

Steering knuckle: a key part with high precision requirements, which is lightweight and high-strength through stamping.

Chassis guard: protects the chassis from external impact and corrosion, and uses stamping technology to form a thin-walled structure.

Future development direction of stamping technology in chassis manufacturing

Intelligence and automation

Through digital production lines and artificial intelligence control, real-time monitoring and optimization of the stamping process can be achieved to improve production efficiency and product quality.

Green manufacturing

Develop low-energy equipment and environmentally friendly stamping lubricants to reduce energy consumption and pollution in stamping processing.

Stamping forming of composite materials

As the application of composite materials in automobile chassis increases, the stamping process needs to adapt to the forming requirements of new materials.

Ultra-high-strength steel forming

For electric vehicles and smart cars, stamping technology will further promote the application of ultra-high-strength steel to improve the safety and strength of the chassis.

The combination of automobile chassis design and stamping technology fully reflects the pursuit of efficiency, precision and greenness in modern manufacturing processes. Stamping technology not only improves the production efficiency and quality of chassis parts, but also promotes the development of lightweight, strength optimization and multifunctional integrated design. In the future, with the widespread application of new materials and intelligent manufacturing technologies, stamping technology will continue to help chassis design move to a higher level and provide strong support for the upgrading and transformation of the automotive industry.

At Xuanmin, we provide customized automotive stamping parts manufacturing with a focus on quality. Contact us today and let us make your project a reality.