With the expansion of industrial production scale and the development of manufacturing technology, wire cutting technology, as a special processing technology, has been widely used in mechanical processing production due to its high processing accuracy, high production efficiency, low power consumption, low manufacturing cost, etc. Wire cutting has changed the past processing mode of split mold and curve grinding, shortened the manufacturing cycle, reduced manufacturing costs, and has high matching accuracy.

What is Wire Cutting

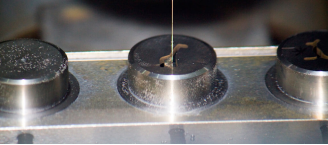

Wire Cutting (EDM-WC) is a precision machining process that uses electrical discharge machining technology to cut. Its core principle is to use high-frequency pulse discharge between the electrode (usually a metal wire) and the workpiece to melt and vaporize the material at the instantaneous high temperature generated at the discharge point, thereby achieving material cutting and processing. During the processing, the electrode wire does not directly contact the workpiece, but removes the material through the action of discharge sparks.

Features of wire cutting technology

There is no significant mechanical chip force during processing. Regardless of the hardness and rigidity of the workpiece, any conductive or semi-conductive material can be processed. However, non-metallic conductive materials cannot be processed.

Small holes and complex-shaped parts can be processed, but blind holes cannot be processed.

The electrode wire loss is small and the processing accuracy is high.

The cutting seam produced during processing is narrow and the amount of metal removed is small, which is conducive to the reuse of materials.

When the workpiece material is too thick, it is difficult for the working fluid to enter and fill the discharge gap, which will affect the processing accuracy and surface roughness.

During the processing, cracks, deformation and other problems may occur on the surface of the workpiece. Before processing, appropriate heat treatment and rough processing should be performed to eliminate defects in material properties and blank shape and improve processing accuracy.

The workpiece can be processed through CNC programming technology, and the processing parameters can be adjusted, which is easy to achieve automatic processing.

Advantages of Wire Cutting Technology

As an advanced precision machining method, wire cutting technology has many unique advantages in the field of material cutting and forming. The following are its main features:

High-precision machining capability

Wire cutting can achieve micron-level machining accuracy, which is suitable for manufacturing parts with strict dimensional requirements.

It has excellent performance in parts that are difficult to complete with traditional machining, such as complex geometric shapes, sharp angles, and small notches.

Applicable to hard materials

It can process high-hardness materials such as titanium alloy, die steel, cemented carbide, ceramics, etc., which are often difficult to process by traditional cutting processes.

No mechanical stress

During the machining process, the electrode wire has no direct contact with the workpiece, avoiding material deformation or internal stress concentration caused by cutting force, which is particularly suitable for the machining of thin-walled parts and precision components.

Low material loss

Using high-frequency discharge to remove materials, the electrode wire only plays the role of conducting current, and its consumption is extremely low, with less waste of workpiece material and good machining surface integrity.

Efficient processing of complex shapes

It can easily achieve cutting of two-dimensional and three-dimensional complex shapes.

With CNC control, multi-axis linkage cutting can be completed to achieve free-form surface and complex contour processing.

High degree of automation

After being equipped with a CNC system, the wire cutting equipment can automatically process according to the preset program, reduce human intervention, and improve processing efficiency and consistency.

Small processing heat effect

The local heat influence range of discharge machining is small, which reduces the thermal deformation of the workpiece and is particularly suitable for parts with high thermal stability requirements.

Strong scalability

It can be used for ultra-fine processing. By adjusting the processing parameters, it can achieve precision processing of extremely thin materials (such as foils) or extremely small features (such as micropores).

Suitable for small batch and personalized production

The processing cost is relatively low, which is particularly suitable for sample making, small batch production and customized production needs.

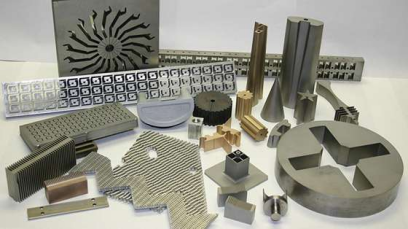

Main application areas of wire cutting technology

Due to its high precision, ability to process complex shapes and adaptability to hard materials, wire cutting technology is widely used in many fields, including the following aspects:

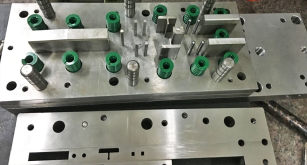

Mold manufacturing

Wire cutting is widely used in the mold industry, mainly used to process high-precision and complex-shaped mold parts, such as:

Injection molds: Processing complex cavities, mold inserts and sliders.

Stamping molds: Used to manufacture precise mold edges, punches and concave molds.

Die-casting molds: Processing cavity structures made of high-hardness steel.

Aerospace

The aerospace field has extremely high requirements for the processing of parts. Wire cutting technology can meet the following needs:

Processing difficult-to-process materials such as titanium alloys and nickel-based alloys.

Manufacturing complex blades, turbine components and avionics equipment housings.

Engine parts: Processing high-precision piston ring grooves, fuel injectors and other parts.

Car body stamping dies: Key components for manufacturing automobile cover dies.

Wire cutting technology is used to process electronic components and connectors, such as:

Precision connectors: Processing miniature plugs and sockets.

Radiator: Cutting complex radiator shapes to improve heat dissipation efficiency.

In the medical industry, wire cutting technology is used to process precision surgical instruments and implants, such as:

Artificial joints: Cutting biocompatible materials such as stainless steel and titanium alloys.

Surgical instruments: Processing high-precision tools required for minimally invasive surgery.

Model manufacturing and small-batch precision processing

Wire cutting can be used to manufacture high-precision prototype parts or small-batch customized parts, such as:

High-end watch parts

Laboratory equipment parts

Military industry

Weapon manufacturing: Processing high-strength parts and special material components.

Military molds: Mold parts used to produce military equipment.

Semiconductors and microelectronics

With the refinement of microelectronics manufacturing processes, wire cutting is used to:

Cutting silicon wafers or other hard and brittle materials.

Manufacturing precision sensors and micro-electromechanical systems (MEMS).

Jewelry industry

Wire cutting is used to process precious metals such as gold, silver and platinum to create complex jewelry designs.

Industrial maintenance

Used to manufacture special parts that cannot be purchased from the market, such as:

Repairing mold cavities.

Making special maintenance tools or fixtures.

Wire cutting technology has penetrated into all walks of life due to its unique advantages. From high-precision molds to complex industrial parts, as well as the growing field of micro-machining, wire cutting is becoming an irreplaceable and important process in modern manufacturing. In the future, with the advancement of technology, its application potential in new material processing and intelligent manufacturing will be more significant.

Xuanmin excels in this field, leveraging years of experience and innovation to unlock the full potential of wire cutting. We transform complex designs into best-in-class products that exceed market expectations. Contact us today! We are ready to work with you to find the perfect solution.