When working with materials such as metal, wood, or plastic, customizing them with precise, permanent designs is often essential. Whether adding a company logo, product details, or simply personalizing an item, the most common methods are laser etching and laser engraving. While both techniques use laser technology to mark a surface, they achieve their goals in slightly different ways.

What is laser etching

Laser etching is a process that uses a high-energy laser beam to quickly and finely remove a thin layer of material on the surface of a material. It is used to mark or decorate various materials. Laser etching can produce fine markings such as text, barcodes, QR codes, patterns and serial numbers on the surface of materials such as metals, plastics, glass, and ceramics. The etching effect is usually shallow and will not affect the structure or strength of the material.

Features of laser etching

Surface micro-processing: Only a very thin layer is removed from the surface of the material, usually between 0.01 and 0.1 mm in depth.

Fast processing speed: Because the amount of material removed is small, laser etching can complete the marking efficiently.

High precision: The laser beam is delicate, making the etched patterns and text very clear, suitable for precision electronic components, medical devices, etc.

Little impact on the material: Etching only acts on the surface layer, maintaining the overall integrity and durability of the material.

As a fine surface marking process, laser etching has many advantages

High precision and clarity: Laser etching can create highly detailed patterns and texts, suitable for marking on small and delicate parts, and provides clear graphic effects.

Fast speed and high efficiency: Very little material is removed during the etching process, and the marking speed is faster, which is suitable for large-scale marking needs and can greatly improve production efficiency.

Non-contact processing: Laser etching is a non-contact processing that does not apply physical pressure to the material, does not damage or change the structure of the material, and is suitable for all kinds of fragile or precision materials.

Durable: Laser-etched marks have high wear resistance. Even if they are frequently contacted or rubbed, the marks will not fade or disappear easily, and are suitable for parts that are used for a long time.

Wide range of applicable materials: Laser etching can be applied to a variety of materials, including metals, plastics, glass, and ceramics, making it widely used in electronics, medical devices, automotive parts, and other fields.

Environmental protection: The laser etching process does not require the use of chemical reagents or inks, has no pollution emissions, and meets green production and environmental protection requirements.

Applications of Laser Etching

Laser etching is widely used in areas that require fast and fine surface marking, including:

Electronic products: brand, model, and serial number markings on mobile phones, computers, and other devices.

Medical equipment: serial numbers and production batch identification on instruments and instruments.

Consumer products: brand logos and decorative patterns marked on product packaging and spare parts.

Automotive parts: wear-resistant and precise markings are required, such as engine parts and dashboard markings.

What is laser engraving

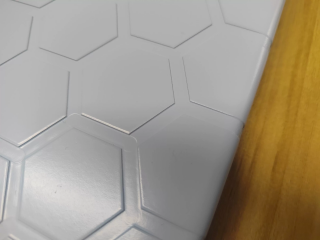

Laser engraving is a technology that uses a high-energy laser beam to make deep cuts or ablations on the surface of a material, producing clear concave or convex effects on the material by precisely controlling the position and intensity of the laser beam. Compared with laser etching, laser engraving penetrates deeper into the material, making the pattern or mark not only visually clear, but also feel the depth of the engraving when touched. Laser engraving has a wide range of applications and can perform high-quality processing on a variety of materials such as wood, metal, glass, leather, stone, etc.

Features of laser engraving

Deep cutting: Laser engraving usually works deeper into the material, usually from 0.1 mm to several mm. The advantage of deep engraving is that it can make the mark more durable and wear-resistant.

Three-dimensional effect: The engraved pattern has a three-dimensional effect, which is suitable for the manufacture of products that require clearly visible marks or design elements.

High precision and clarity: Laser engraving can create highly accurate and detailed patterns, suitable for the production of complex graphics, text, logos and serial numbers.

High durability: The laser engraved pattern is highly wear-resistant and suitable for products that need to be used for a long time or withstand high wear.

Advantages of laser engraving

Permanent marking: The depth of engraving ensures that the mark will not be worn away due to daily use, friction or chemical cleaning agents.

A wide range of applicable materials: It can be engraved on a variety of hard or soft materials, such as wood, metal, plastic, stone, glass, etc.

Environmentally friendly and pollution-free: Laser engraving is a non-contact processing method, does not require chemical solvents or inks, does not produce polluting gases, and meets environmental protection requirements.

Strong adaptability: It is suitable for surfaces of various sizes and shapes, and the engraving effect will not be affected by minor unevenness on the surface of the material.

Applications of laser engraving

Industrial manufacturing: Used to mark durable serial numbers, part numbers and other permanent information in industries such as automotive, aviation, and mechanical equipment.

Arts and Crafts: For personalized decoration and gift engraving, suitable for engraving complex patterns and high-resolution graphics.

Advertising and Signage: Engrave text and patterns on metal, wood and plastic signs to create high-quality logos for stores, buildings and display booths.

Electronics: Suitable for engraving company brands, equipment models and other information on metal or plastic housings.

Jewelry and accessories: engrave unique patterns or text on rings, bracelets and other accessories for personalized customization.

The Difference Between Laser Etching and Laser Engraving

| Features | Laser Etching | Laser Engraving |

| Depth | Shallow, usually 0.01 to 0.1 mm | Deep, up to several mm |

Effect | Surface changes color or creates subtle indentations | Produce more obvious deep indentations |

| Material removal | Removes a small amount of surface layer | Removes more material |

| Applicable materials | Metal, plastic, glass, ceramic, etc | etal, wood, stone, glass, plastic, etc |

Processing speed | Usually faster, suitable for quick marking | Slower, suitable for deeper engraving and three-dimensional patterns |

Although the two processes are similar, they have a number of significant differences that affect their applications. Generally speaking, laser etching is better suited for artistic products that need to be less durable, while laser engraving produces highly durable products.

Need laser marking on machined parts? Xuanmin offers custom laser etching and engraving services tailored to your needs.We also offer surface treatment and other manufacturing services such as sheet metal stamping, injection molding, and 3D printing. You can contact us today to request a quote.