Powder spraying is a common metal surface treatment process, which is widely used in metal processing to improve the corrosion resistance, wear resistance and aesthetics of workpieces. The following is a basic introduction to the powder spraying process, including its principles, advantages, and application areas.

Definition of Powder Coating

Powder coating is a process in which fine powdered coating is evenly sprayed on a metal surface, and then heated at high temperatures to melt and solidify the coating on the metal surface. This process uses electrostatic spraying to adsorb powder on the surface of the workpiece, and forms a smooth, solid coating in the subsequent baking process.

Process principle of powder spraying

Powder spraying mainly consists of two parts: spraying process and curing process.

Spraying process

During the spraying process, powder coating is sprayed onto the surface of metal workpiece through a spray gun, usually by electrostatic spraying. The electrode of the spray gun makes the powder charged with static electricity, and the potential difference is formed after the workpiece is grounded, so the charged powder is adsorbed on the surface of the workpiece. This method can make the coating evenly distributed and reduce the waste of coating.

Curing process

The workpiece after powder spraying needs to be baked at high temperature to melt the powder coating and form a dense coating on the metal surface. The temperature of the curing process is usually between 180℃ and 200℃, and the time is about 10-20 minutes, depending on the type of coating and the workpiece material.

Advantages and Disadvantages of Powder Coating

Advantages

Environmentally friendly: Powder coatings do not contain solvents, and no harmful gases will be volatilized during the spraying process, which is environmentally friendly.

Good durability: Powder spray coatings have excellent adhesion, wear resistance and corrosion resistance, and are suitable for outdoor or parts that are susceptible to wear.

Uniform coating effect: Electrostatic spraying makes the powder evenly distributed, which can effectively cover the edges, corners, grooves, etc. of the workpiece to form a smooth and traceless surface.

Efficient and economical: Powder can be recycled to reduce waste, and the spraying process is also simpler and more efficient, saving production costs.

Disadvantages

Limited to high-temperature workpieces: Powder spraying requires high-temperature curing, so it is not suitable for heat-sensitive materials (such as plastics, etc.).

High equipment cost: Powder spraying equipment such as electrostatic spray guns and ovens are expensive and require a large factory space.

Limited color selection: Although powder coatings have more colors, their diversity is not as good as liquid coatings, and color matching is more difficult.

Application fields of powder coating

Due to its corrosion resistance, weather resistance and aesthetics, powder coating is widely used in many industries, mainly including:

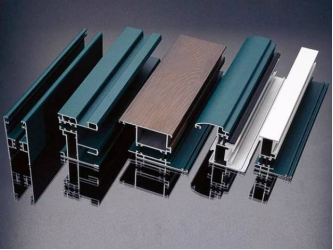

Architecture and home

Powder coating is widely used in metal doors, windows, railings, furniture and other outdoor or indoor metal structures to enhance their durability and decorativeness.

Automotive industry

Automobile wheels, frames, chassis parts, etc. need to be exposed to the outside for a long time and are susceptible to corrosion, so most of them are treated with powder coating to improve durability and aesthetics.

Home appliance industry

The outer shell of home appliances such as washing machines, refrigerators, and ovens uses powder spraying technology, which can withstand daily wear and moisture and extend the service life of the product.

Industrial equipment

Agricultural machinery, construction machinery, etc. need to cope with harsh working environments. Powder spraying can enhance the corrosion resistance of parts and extend the service life of equipment.

Sports and outdoor equipment

Outdoor fitness equipment, bicycles, skateboards and other outdoor sports equipment, the wear resistance and UV resistance of powder spraying enable it to maintain a long-term appearance and performance.

Powder spraying is a high-quality surface treatment technology that is not only environmentally friendly, but also can enhance the durability, wear resistance and aesthetics of metal parts. In the future, with the continuous improvement of coating technology and spraying equipment, powder spraying will continue to expand its application in manufacturing, construction, automobiles and other fields, and is expected to play a greater role in industrial environmental protection.

Powder coating should be guided by specific project requirements, including material type, desired finish, environmental considerations, and budget constraints. Xuanmin offers amazing surface treatment services to meet all of your needs. Contact us today to get started!