CNC (Computer Numerical Control) machining and metal casting are two commonly used metal processing processes in modern manufacturing. They each have their own characteristics and are suitable for different products and production needs.When it comes to manufacturing metal parts, product designers may have a variety of manufacturing methods to choose from. Two common options are casting and CNC machining. But to determine which is best for your specific application, what factors should you focus on to make an informed decision?

Concepts of CNC machining and metal casting

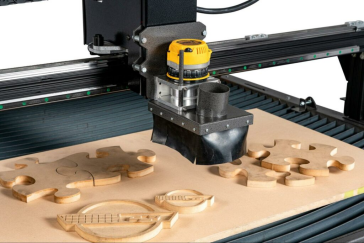

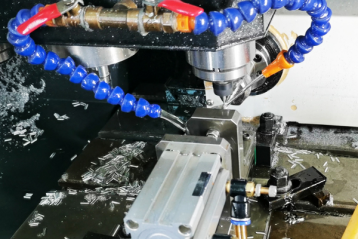

CNC machining

CNC (Computer Numerical Control) is computer numerical control machining, which is to control machine tools through computer programming to perform material cutting, drilling, milling and other operations to process raw materials into specific shapes and precision. CNC machining uses CNC lathes, CNC milling machines, CNC drilling machines and other equipment to accurately control the movement of the tool through programmed instructions to achieve high-precision machining.

Metal casting

Metal casting is a process in which molten metal materials are poured into a mold with a specific shape and cooled and solidified to form a solid casting. Casting technology has a long history and is suitable for large-scale parts production. Common casting methods include sand casting, precision casting, die casting, etc. Different processes are suitable for different product requirements.

The difference between CNC machining and metal casting

Manufacturing method

CNC machining is a process of removing materials to shape the workpiece, which is a "subtractive" process;

Metal casting is a process of injecting molten metal into a mold and cooling it, which is an "additive" process.

Applicable materials

CNC machining is generally suitable for materials with higher hardness, such as metal materials such as steel, aluminum, copper and its alloys, as well as some engineering plastics;

Metal casting is suitable for all kinds of metals, such as cast iron, cast steel, aluminum alloy, copper alloy, etc.

Machining accuracy

CNC machining has a high machining accuracy, which can reach 0.01 mm or even higher;

The casting accuracy is relatively low, and subsequent processing is usually required to achieve higher accuracy.

Production efficiency

CNC machining is suitable for small and medium-sized batch production, with short programming and workpiece positioning preparation time, but long single-piece processing time;

Metal casting is suitable for mass production, and due to the use of molds, the single-piece production efficiency is high.

Advantages and disadvantages of CNC machining and metal casting

Advantages of CNC machining

High precision and stability: CNC machining controls the tool movement through the CNC system, which can achieve extremely high machining accuracy (usually up to 0.01 mm), and is suitable for manufacturing high-precision parts.

Flexibility: CNC machine tools are flexible in programming and suitable for the production of workpieces with complex geometric shapes. They are highly adaptable and especially suitable for customized small-batch production.

High efficiency and automation: CNC machining can achieve unattended continuous operation, and improve machining efficiency and reduce human interference through functions such as automatic tool change.

Disadvantages

High equipment cost: CNC machine tools are expensive, and require high skills for operators, and the initial investment is large.

Limited material utilization: CNC is a subtractive machining process that requires material removal, especially when machining complex parts, the material loss may be large.

Not suitable for mass production: CNC machining takes a long time, and the single-piece production efficiency is limited, which is usually not suitable for mass production.

Advantages of metal casting

Low cost, suitable for mass production: Casting is suitable for mass production, especially when using molds, the cost per piece is greatly reduced.

Wide range of materials: Casting can be used for a variety of metal materials (such as cast iron, cast steel, aluminum alloy, etc.), and is suitable for some high-temperature or high-hardness materials that are difficult to form by other methods.

Suitable for large and complex structural parts: The casting process can produce large-sized and complex parts, which is difficult to achieve in subtractive processes such as CNC.

Disadvantages

Low precision and surface quality: The precision of castings is usually lower than that of CNC processing, and there may be problems such as surface roughness, which usually require subsequent processing.

High mold cost and poor production flexibility: The mold making cost is high, and casting is not suitable for small batch or customized production. In addition, the mold design and production cycle is long, and the response speed to product design changes is slow.

Defects are difficult to avoid: Castings may have defects such as pores and shrinkage holes during the cooling process, affecting the mechanical properties and appearance quality of the parts.

Application fields of CNC machining and metal casting

Application fields of CNC machining

Aerospace: used to manufacture high-precision aviation parts, such as turbine blades, engine parts, etc.

Automobile manufacturing: used to make high-precision mechanical parts such as automobile engines and transmission systems.

Electronic products: used to process metal shells and internal components in mobile phones, computers and other devices.

Medical devices: The high-precision characteristics of CNC are suitable for manufacturing metal parts in medical devices, such as surgical instruments, implants, etc.

Application areas of metal casting

Heavy industry: In large-scale machinery and equipment, power generation equipment, and mining machinery, casting is an ideal choice for mass production.

Automotive industry: Engine cylinders, brake discs, suspension arms, etc. are mostly made using casting technology to reduce costs.

Construction industry: Used to make various metal structures and support parts.

Consumer electronics: The housings, frames, and brackets of small electronic devices are often formed using die casting technology.

CNC machining produces stronger, more precise parts than metal casting due to its uniform structure and accuracy, making it ideal for high-performance applications such as the aerospace and automotive industries. However, casting is well suited to mass production and can produce large, complex shapes at a lower cost.

For businesses that need CNC or casting services, Xuanmin is a trusted supplier. With cutting-edge technology and professional craftsmanship, Xuanmin can provide precision CNC machining and cost-effective casting solutions. Customers can trust Xuanmin to provide high-quality customized results that meet the highest standards of metal manufacturing.