As the manufacturing industry moves towards automation and high precision, the importance of welding technology becomes increasingly prominent. As the core technology of the welding industry, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding technologies are leading the innovation in the welding field and have become key tools for improving product quality and efficiency in many industries.

Physical comparison between MIG and TIG welding

1. MIG welding

Full name: The full name of MIG welding is Metal Inert Gas Welding, which is commonly used in GMAW (Gas Metal Arc Welding) gas shielded metal arc welding.

Electrode material: The electrode used in MIG welding is a metal wire, which is used as a filler material and electrode. It melts continuously during the welding process and becomes part of the weld.

Gas: Generally, inert gas (such as argon, helium) or active gas (such as carbon dioxide) is used for protection to prevent oxidation of the welding area.

Advantages: Fast welding speed, high production efficiency, suitable for automated welding and continuous welding.

Application: MIG welding is commonly used for welding of metals such as steel, aluminum, copper and magnesium, and is particularly suitable for welding thicker materials and large areas, such as manufacturing and automotive industries.

2.TIG welding

Full name: The full name of TIG welding is Tungsten Inert Gas Welding, also known as GTAW (Gas Tungsten Arc Welding) gas shielded tungsten arc welding.

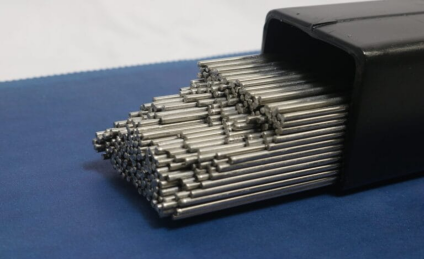

Electrode material: TIG welding uses tungsten as a non-consumable electrode. The high melting point of tungsten prevents it from melting during welding, and welding filler materials can be added manually as needed.

Gas: Inert gases such as argon or helium are usually used to protect the welding area and prevent oxidation.

Advantages: High quality welds, less spatter during welding, suitable for fine welding, and beautiful welds.

Application areas of MIG welding

MIG welding is suitable for welding large areas and thicker materials due to its high efficiency and fast welding speed, especially for automated production lines. The following are its main application areas:

Automobile manufacturing

MIG welding is used for welding car bodies, chassis, exhaust systems, etc. Its high efficiency and relatively low cost are very suitable for large-scale automobile production.

Machinery manufacturing and heavy equipment

In the manufacture of large equipment such as machinery and equipment, agricultural machinery, and construction machinery, MIG welding is used to connect thick metal plates and structural components. Its fast welding process can shorten the production cycle.

Shipbuilding and marine engineering

MIG welding is used in shipbuilding to weld hulls, brackets and other large structures, especially those with high structural strength requirements. Its gas protection can prevent oxidation during welding.

Building steel structure

MIG welding is often used in large-area steel structures such as steel frames and bridges in buildings to quickly complete welding tasks, especially in high-strength steel structures.

Pipeline welding

MIG welding is also used for welding thicker pipelines in industries such as oil and gas, and is suitable for stable environments.

Application fields of TIG welding

TIG welding is characterized by fine control and high-quality welds. It is suitable for thin materials and scenes with extremely high requirements for welding quality. The following are its main application fields:

Aerospace

TIG welding is widely used in the manufacture and maintenance of aerospace equipment such as aircraft and rockets. Especially in the welding of high-strength light metals such as aluminum alloys and titanium alloys, TIG welding can provide precise and defect-free welds.

Medical devices

Medical devices (such as surgical tools, medical stents, etc.) are usually made of stainless steel or titanium alloys, and have extremely high requirements for weld quality. The high precision and cleanliness of TIG welding make it the preferred welding method for medical device manufacturing.

Food processing equipment

Food processing equipment generally uses stainless steel materials, which require smooth weld surfaces to prevent bacterial growth. TIG welding can ensure high-quality, pollution-free welds that meet the hygiene standards of the food industry.

Electronics and precision instruments

TIG welding is widely used in the manufacture of electronic equipment and small precision instruments. It can perform precise welding on thin metal plates and complex structures to ensure the stability and durability of the instrument.

Decorative metal products

Due to the beautiful welds of TIG welding, it is often used in the production of decorative metal objects, such as metal sculptures, furniture, railings, etc. In these applications, the visual effect of welding is as important as the quality.

Pipe and valve welding

In the fields of chemical industry and nuclear industry, TIG welding is widely used in the welding of pipes and valves of materials such as stainless steel and titanium to ensure the corrosion resistance and sealing of the welds.

Of the four main types of arc welding processes used in sheet metal fabrication, MIG vs. TIG welding is the most common among sheet metal fabricators. Both methods have their own unique advantages, and choosing one requires understanding their techniques, pros, cons, and other differences. Understanding these factors will enable you to select the appropriate welding process for your project.

Do you have challenges related to MIG and TIG welding? Contact us Our team will provide the most suitable solution for your project.

In addition, if you have welding needs, Xuanmin is your best partner. We are a rapid prototyping company specializing in sheet metal fabrication services for mass production. We are committed to providing high-quality products with short delivery time and competitive prices to help you achieve your welding needs.