Polyamide is a thermoplastic that belongs to the class of synthetic fibers, commonly known as nylon. Polyamide fibers and nylon materials are increasingly used in many industries due to their superior performance, toughness, and versatility. Understanding the differences between these materials is important to help you make an informed decision when choosing the right material for your product.

Characteristics of polyamide

Polyamide has many impressive properties, so it can be widely used in many products.

Wear resistance

Polyamide has good strength and wear resistance. It can withstand heavy loads and is not easy to break or deform under impact. In addition, it has excellent chemical resistance and UV resistance, making it an ideal material for outdoor applications.

Flexibility and elasticity

Polyamide has high flexibility and good elasticity. It can be stretched without deformation and quickly returns to its original state. So it is suitable for making fabrics such as sportswear and underwear.

Heat resistance

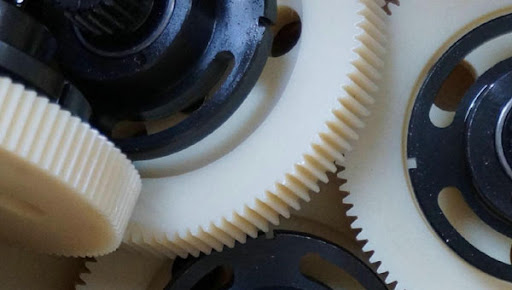

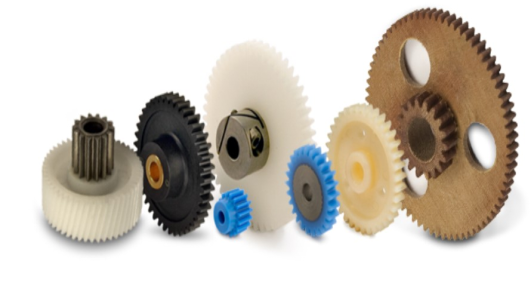

Polyamide has excellent heat resistance and can maintain its structure even at high temperatures. This makes it suitable for applications under high temperature or friction conditions. Therefore, it is widely used in the manufacture of engine parts such as gears and bearings.

Chemical resistance

Polyamide has the characteristics of being resistant to chemicals such as acids, alkalis and organic solvents. However, it is affected by strong acids and polar solvents. The specific chemical resistance depends on the type of polyamide and the conditions of use.

Characteristics of nylon

Nylon has many of the same characteristics as polyamide, but nylon also has some special characteristics that are different from polyamide.

Excellent mechanical properties

Nylon is wear-resistant, lightweight, has high mechanical strength and good toughness.

Good self-lubrication and friction resistance

Nylon has good self-lubrication and a small friction coefficient, so it has a long service life as a transmission component.

Excellent heat resistance

Highly crystalline nylons such as nylon 46 have a high heat deformation temperature and can be used for a long time at 150°C. After PA66 is reinforced with glass fiber, its heat deformation temperature reaches more than 250°C.

Excellent electrical insulation properties

Nylon has a high volume resistivity and high breakdown voltage resistance, making it an excellent electrical and electrical insulation material.

Excellent weather resistance

Nylon can be used as clothing material such as waterproof clothing and is suitable for outdoor activities such as camping and hiking.

Water absorption

Nylon has high water absorption, and the saturated water can reach more than 3%. It affects the dimensional stability of the parts to a certain extent.

Polyamide has a wide range of applications covering multiple fields

In the field of textiles and fibers: it has become an ideal choice for products such as clothing, socks, bedding, ropes, etc.;

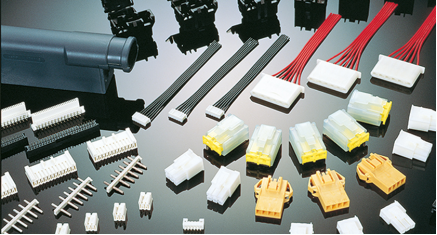

In the field of engineering plastics: it helps in the manufacture of mechanical parts, automotive parts, electronic product housings, piping systems, etc.;

In the automotive field:it has become the preferred material for automotive parts and components due to its high strength, heat resistance and chemical corrosion resistance;

In the field of packaging materials:polyamide films and packaging films have won the favor of the food and electronic product packaging market with their moisture-proof and wear-resistant properties;

In the field of medical devices and medical supplies:it has become an important raw material for medical devices, surgical instruments, catheters, artificial joints and other products with its good biocompatibility and corrosion resistance;

In the field of electronic products: it plays an irreplaceable role as an insulating material, wire and cable casing, electronic component bracket, etc.

nylon has been widely used in many fields

In the textile industry: nylon is used to make clothing, socks and household items;

In the machine manufacturing field: nylon's light weight, durability, heat resistance and chemical resistance are suitable for the production of many machine parts such as bolts, nuts and screws;

In clothing manufacturing: Nylon can be made into everything from shirts, swimsuits and raincoats to military items such as ropes, ponchos and tents;

In the fishing industry: Nylon is an ideal material for making fishing nets because it is durable, lightweight and highly resistant to abrasion. In particular, fishing nets have high tensile and compressive strength, which helps them to bear large weights without breaking.

Nylon materials have excellent properties, including strength, wear resistance, chemical resistance, lightness and flexibility, as well as thermal stability. These properties make them widely used in textile, industrial, electronic and automotive fields. With the continuous development of technology, nylon materials will continue to play an important role in various industries and bring more innovation and application opportunities in different fields.

From clothing to machinery manufacturing, we can see the application of nylon and polyamide materials everywhere because it is durable, tough, damage-resistant, and relatively inexpensive. The material is also stable and easy to injection mold. If you are looking for PA (nylon) engineering plastic compounds at a good price, Xuanmin is ready to provide you with a good price at the same time.