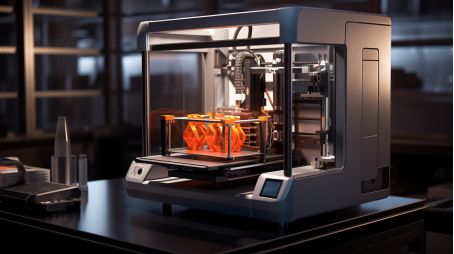

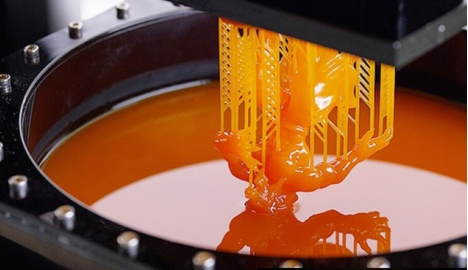

3D printing is a revolutionary technology that can be used in many different ways for many different purposes. From gaming to prosthetics, you name it. While the uses and applications of 3D printing are vast, one thing remains constant—you need to choose the right printing material. PLA and ABS are the two most common thermoplastic materials used in 3D printing, each with unique properties and advantages for different applications.

Material Introduction

ABS: It is a petroleum-based plastic with high strength, heat resistance and impact resistance, so it is very common in industrial applications. It requires high temperature when printing and can release a small amount of smoke, so it generally requires a closed environment and ventilation conditions.

PLA: It is a biodegradable plastic, mainly made of lactic acid extracted from plants such as corn starch or sugarcane, which is environmentally friendly and non-toxic. It is easy to print and suitable for most open 3D printers, but has low heat resistance and impact resistance.

Advantages of ABS

Strength and durability: More durable than PLA, suitable for manufacturing parts that need to withstand mechanical stress.

High heat resistance: Can withstand higher temperatures, suitable for mechanical and electrical parts.

Easy post-processing: Can be sanded, drilled, and acetone can be used for surface smoothing.

Advantages of PLA

Biodegradability and environmental protection: PLA is an environmentally friendly material suitable for applications that focus on sustainability and safety.

Low warping: Not easy to warp during printing, suitable for beginners and printing that does not require a heated platform.

Easy to print: PLA can be melted at a relatively low temperature, making it easy to print.

Material comparison

| feature | ABS | PLA |

Strength | High, impact resistance | Medium, brittle |

Heat resistance | High (suitable for high temperature environment) | Low (will deform at lower temperature) |

Printing difficulty | High, requires heating platform and ventilation equipment | Low, suitable for beginners |

Environmental protection | Not environmentally friendly, petroleum-based materials | Environmentally friendly, biodegradable |

Post-processing | Can be polished, sprayed, acetone polished | Difficult to post-process, need to be handled with caution |

Material Application

ABS Application: Suitable for manufacturing high-durability parts, such as automotive accessories, power tool housings, home appliance parts and other industrial applications; due to its high heat resistance, it is also suitable for mechanical parts.

PLA Application: Mainly used for prototyping, educational projects, art and decorations such as toys and models; suitable for projects that require fine details and low strength requirements.

ABS is more suitable for industrial and durable applications, and is suitable for projects with high requirements for strength and heat resistance; PLA is popular in the home and beginner markets for its environmentally friendly and easy-to-print features, and is suitable for applications with high requirements for environmental protection and aesthetics.

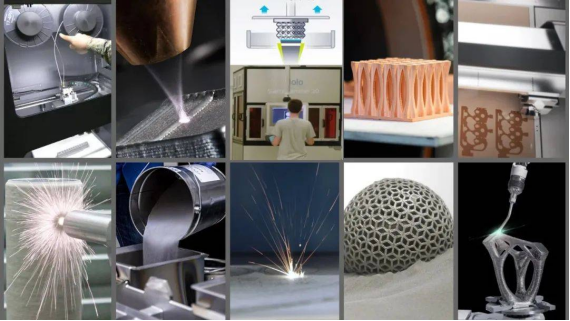

Xuanmin can provide all your 3D printing services. We offer competitive FDM, SDA, SLS services, as well as a wide range of material and surface treatment options. That's not all. Our team of trained experts is ready and willing to provide you with technical support, design guides and case studies. This will be especially convenient when choosing between PLA and ABS.