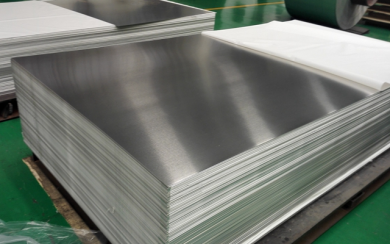

Aluminum's versatility makes it durable and the most commonly used metal for a wide range of applications, from household items such as kitchen utensils to industrial-grade products. This special metal is found in large quantities on the earth's surface, and its unique properties make it suitable for complex applications. In manufacturing industries such as stamping, aluminum is treated with anodizing to increase hardness, corrosion resistance, and sometimes aesthetics.

Concept of aluminum oxide

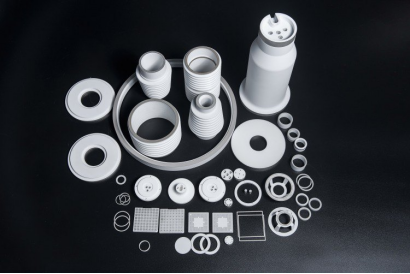

Alumina is a white, odorless, crystalline powder that is insoluble in water. The chemical formula is AI203 and it is amphoteric in nature. This substance is widely used in various industries and also in commercial applications. To this day, this chemical remains one of the most versatile advanced ceramic materials in terms of use and manufacturing.

Effects of aluminum oxide on Humans

Aluminum is a naturally abundant metal on Earth, usually found in the form of aluminum oxide or bauxite. It is formed when aluminum is exposed to air and forms a thin layer on it. This is why aluminum oxide is corrosion resistant.

This metal can be considered safe because it does not cause toxic reactions. However, long-term exposure can still lead to health irritation or some more serious health problems. Despite this, in today's industry, chronic exposure rarely occurs.

Except for skin irritation and general mild chronic toxicity, there is almost no acute toxicity. This is why this metal compound is one of the most common choices in the production of advanced ceramics. However, it is important to continue to use protective equipment such as masks to avoid inhaling dust and gloves to prevent skin irritation.

Aluminum oxide has a wide range of uses

Refractory materials: Alumina has a high melting point and good refractory properties, and is often used as a refractory material, such as refractory bricks, refractory crucibles, refractory tubes, etc.;

Ceramic materials: Alumina has good mechanical strength and high temperature stability, and is often used as a ceramic material, such as ceramic knives, ceramic rollers, ceramic plates, etc.;

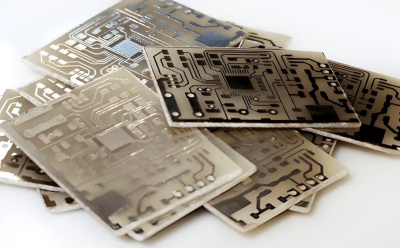

Electronic components: Alumina has a high dielectric constant and low loss, and is often used as electronic components, such as capacitors, inductors, etc.;

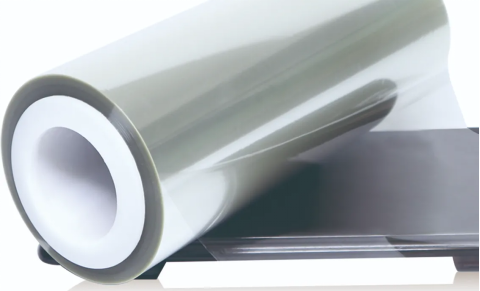

Coating materials: Alumina has good wear resistance and corrosion resistance and is often used as coating materials, such as ceramic coatings, anti-corrosion coatings, etc.

Catalysts and catalyst carriers: Alumina has a large specific surface area and good thermal stability, and is often used as a catalyst and catalyst carrier, such as automobile exhaust purification catalyst and catalyst carrier.

Daily cleaning of aluminum oxide surface

Use a detergent to clean the aluminum surface. Sodium alkylbenzene sulfonate, sulfuric acid, acetic acid and other detergents can be used.

Use grinding and polishing tools to treat the aluminum oxide layer. Abrasive cloth, sandpaper, grinding wheel or grinding machine can be used for treatment.

Use electrolytic deoxidation to clean the aluminum surface. Electrolyte can be used to remove the aluminum oxide layer on the surface.

Use a medium for cleaning. Sand, glass beads and other media can be used for sandblasting to remove the oxide layer on the surface. It should be noted that when cleaning the aluminum surface, you should avoid using too strong a detergent, otherwise it may cause damage to the aluminum.

With Xuanmin, you get quality-focused anodizing, short lead times and easy quotations at competitive prices. Are you considering smooth operation and high-quality aluminum anodizing at a low price? Contact us!