When choosing materials for different applications, people generally prefer materials that are lighter, cheaper, and energy-efficient. Therefore, the choice between titanium and aluminum often arises. Both titanium and aluminum have a unique set of properties. Depending on the specific requirements, they also have unique advantages. Therefore, it is necessary to have a comprehensive understanding of these metals in order to make a more informed choice for a specific application.

Differences between Aluminum and Titanium

Why do we need to compare aluminum and titanium? That is, each metal has its own unique properties and advantages, and these differences determine the specific scenarios that each metal is best suited for.

Characteristics

When we talk about metals, we tend to focus on their characteristics, such as strength, weight, corrosion resistance, heat resistance, flexibility, etc. It is crucial to understand the material characteristics of aluminum and titanium, because these characteristics can help us find out the better material when we are hesitant about choosing the material for a product or component. Now, let's use a table to summarize their differences in mechanical properties.

| Properties | Aluminum | Titanium |

| Tensile strength, MPa | 90-690 | 230-1400 |

| Yield strength, MPa | 200-600 | 170-480 |

| Density, g/cm | 2.71 | 4.54 |

| Thermal conductivity, W/mK | 210 | 17 |

| Electrical conductivity, referenced to copper | 64% | 3.1% |

| Melting point, °C | 660 | 1650-1670 |

Strength and density

Titanium is much stronger than aluminum. The tensile strength of titanium is between 230 and 1400MPa, while the tensile strength of aluminum is generally between 90 and 690MPa.

Aluminum is lighter than titanium. The density of aluminum is 2.71, which is lower than the density of titanium, which is 4.54. It is reported that the weight of aluminum of the same volume is about 60% of that of titanium. When the product needs to be lifted quickly and easily, aluminum is a better choice.

Thermal conductivity

Thermal conductivity indicates the ability to transfer energy and heat, and is a measure of a metal's suitability for thermal applications. Aluminum has a much higher thermal conductivity of 210 W/mk, while titanium has a thermal conductivity of only 17 W/mk. Aluminum is better suited for applications such as heat exchangers, cookware, and automotive parts.

Electrical conductivity

Copper is known to be a good conductor of electricity and is the benchmark against which other materials are compared, with a conductivity of 100%. Aluminum is much better at 64% of copper, while titanium is about 3.1%. This means that aluminum is an ideal conductor of electricity, while titanium is better at being a resistor.

Melting Point

The melting point indicates the temperature limit at which a metal changes from a solid to a liquid state. Titanium has a melting point of 1650 – 1670 °C, with specific values varying depending on the grade. Aluminum has a much lower melting point of around 660 °C. This property allows titanium to withstand extreme heat and maintain structural integrity.

Corrosion resistance

Corrosion is the deterioration of metals over time, usually due to water, air or chemicals. When aluminum comes into contact with oxygen, a chemical reaction occurs, forming a thin layer of aluminum oxide. This oxide layer helps protect the aluminum from further corrosion. However, titanium is more corrosion resistant than aluminum. This is mainly because the titanium oxide film formed on the surface is thicker and denser, which can more effectively block corrosive substances.

Machinability

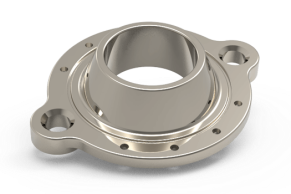

Machinability refers to how easily a material can be machined or formed using various tools and techniques. Interestingly, with the use of CNC turning and milling, it has become easier to machine aluminum and titanium in less than a day. Aluminum is known for its excellent machinability. This is because it is inherently softer and more ductile compared to titanium. However, titanium is more challenging to machine due to its hard nature. However, it can still be machined accurately using tools and techniques. Also consider machining waste when choosing a material to machine. It is common to use aluminum to make prototypes and then switch to titanium to produce parts due to its low cost.

Applications of aluminum and titanium

Applications of aluminum

Aerospace Industry--Aluminum alloy is one of the important materials in the aviation industry and can be used to manufacture rivets, aircraft propellers, radiators, high-strength aircraft parts, etc.

Marine Industry--Aluminum alloy has excellent comprehensive properties and is used to produce ship hulls, support structures, support facilities, pipelines, etc.

Chemical Industry--Aluminum is widely used in the chemical industry to manufacture complex corrosion-resistant parts, such as cylinders, pipe fittings, valves, pumps, pistons, etc.

Metal Packaging--Aluminum alloy is used for food and beverage packaging, such as aluminum foil, beverage cans, etc. Its excellent barrier properties effectively extend the shelf life of the product, and aluminum has high recyclability, which meets the needs of sustainable development.

Construction Industry--Aluminum alloy is widely used in window frames, doors and curtain walls. Its corrosion resistance and low maintenance cost make it suitable for modern architectural design. The appearance of aluminum alloy can also enhance the overall effect of the building and provide long-term durability.

Electronic Industry--Aluminum alloy is used in electronic products such as laptop shells and mobile phone bodies. The lightness and good heat dissipation performance of aluminum not only improve the durability of the equipment, but also meet the requirements of modern consumers for appearance.

Titanium Applications

Titanium alloys are mainly used in aviation, daily necessities, marine engineering, construction industry, chemical industry, sports equipment and other fields.

Aerospace Industry--Titanium is widely used in aircraft structures, engine components and wheels. Its high strength-to-weight ratio enables aircraft to withstand greater loads without increasing weight, while its high temperature resistance ensures stability in extreme environments, which is critical to flight efficiency and safety.

Marine Engineering--Seawater desalination pipelines, offshore oil drilling pumps, valves, pipe fittings, etc.

Chemical Industry--Soda ash, plastics, petrochemical point dissolution tanks, reactors, distillation towers, concentrators, electrodes.

Sports Equipment--Golf heads, tennis rackets, badminton rackets, ski poles and ice skates.

Medical Devices--Titanium is mainly used in implants and surgical instruments in the medical field. Titanium's corrosion resistance and biocompatibility can effectively avoid infection and rejection reactions, and it is suitable for long-term implantation, such as joint prostheses, dental implants, etc., to ensure patient safety.

Xuanmin is ISO 9001 and AS9100 certified, and our quality management system is supported by an experienced team of quality control inspectors. We also offer a variety of value-added services, including assembly, packaging, and shipping, helping customers save time and money.

Contact us today to learn more about our aluminum and titanium processing capabilities or to request a quote for your project.