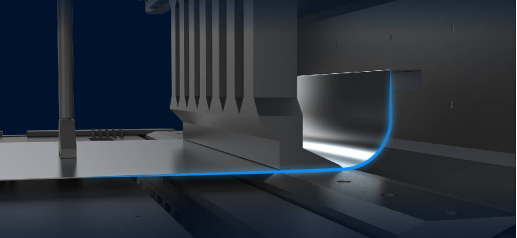

Sheet metal bending processing technology is the bending and forming of metal sheets. It is carried out on a plate bender. The workpiece to be formed is placed on the plate bender, the brake shoe is lifted with a lifting lever, the workpiece slides to the appropriate position, and then the brake shoe is lowered onto the workpiece to be formed. The bending of the metal is achieved by applying force to the bending lever on the plate bender.

Bending Sheet Metal Specific Operations

There are a variety of machines that can be used to bend sheet metal. The most popular type of equipment, often found in small machine shops, is the press brake. It can be operated manually or by computer numerical control (CNC) and hydraulic systems. Both machines work on the same principle, but the operator experience varies. The following process focuses on how the CNC press brake operates:

Determine Design Parameters

Before using a sheet metal press brake, determine the design parameters such as the force required, the bend line (where the force is applied), and the bend sequence (if any). You also need to decide which die to use to make the bend.

Set Up the Press Bending Brakes

The CNC press brake must be programmed with the calculated information to set up the press brake. Only then can it determine the correct bend and the sequence to make the bends in the metal. The appropriate tools and dies must be tightened to prepare the press and brakes for the bend.

Align the Parts

Align the metal around the dies and tools. Through the operation of the machine, the sheet metal will bend at the bend line.

Engage the Press Bender

Press the release button to apply the force parameters entered into the CNC press brake in the second step. Once the press brake has bent the metal, the part is removed and ready for the next stage of production.

Types of Sheet Metal Bending

Air Bending: This uses two dies; an upper die (also called a punch) and a bottom die. The bottom die has a V-shaped opening. The punch forces the sheet metal into the bottom die. Air bending is not as precise as other methods.

Bottoming: In this method, the sheet metal is pressed onto the face of the die by the punch. The metal is then angled the same as the angle of the die. The optimum width of the v-die opening is 6 times the material thickness for a sheet of about 3 mm thick and 12 times the material thickness for a 12 mm thick sheet.

Casting: This is similar to air bending. However, the force used is typically 5 to 30 times that of air bending. This gives a much higher degree of precision.

Folding: A clamp beam is used to hold the longer edge of the metal. The beam is free to rise and bend the sheet around the bend contour. Both negative and positive bend angles are possible.

Erasing: The long edge of the sheet is clamped and the tool moves up and down, bending the metal around the bend contour. Erasing is relatively faster than folding but has a higher tendency to produce scratches or damage the sheet.

Rotational Bending: The upper die is made of a freely rotatable cylinder. The curved shape is cut into it, as well as a matching bottom die. As the roller contacts the sheet, it rotates. This process causes the sheet to bend.

Meshing Bending: An offset bend. The two opposite bends are less than 90 degrees each. A neutral web separates the opposite bends.

Integral Parameters for Sheet Metal Bending

When it comes to the bending process, there are multiple parameters that manufacturers and designers must consider. These design requirements are fundamental features of any sheet metal bend and it is recommended to adhere to their standards to ensure excellent results.

Below are the 6 most important parameters for any sheet metal bending operation.

Bend Line: The bend line is a straight line on the surface of the sheet that marks the start to end point of the bend on both sides. The industry standard for bend lines is to maintain a distance of 5 times the sheet thickness between the inner edge of the bend and the outer side of the bend.

Bend Radius: The bend radius is the distance from the bend axis to the inner surface of the material between the two bend lines. It is usually recommended to use a bend radius that is at least as large as the material thickness. The larger the bend radius, the better, but using a radius that is less than the material thickness will reduce the load-bearing capacity of the part.

Bend Angle: The angle that the bend makes with an imaginary vertical line coming from the axis. The industry convention for bend angles is to ensure that the flange length must be 4 times the thickness, rather than a specific number. It is also a good practice to keep all bend angles the same.

Neutral Axis: The neutral axis is the portion of the sheet that maintains its original length because it is neither stretched nor compressed. It is an independent parameter with no legal restrictions or guidelines for its position. However, the accuracy of other factors such as bend radius and angle plays a vital role in determining the performance of the final product. Therefore, the more accurate these factors are, the better the product is likely to perform.

K-factor: The K-factor of a material is a measure of its position and is determined by dividing the distance between the material and its thickness (t) by its T. The K-factor is affected by a range of factors, including material type, bending process, bend angle, etc. To ensure the best results, the K-factor should be in the range of 0.25 to 0.50. The K-measure can be calculated by the formula K = T/t.

Bend allowance: To produce accurate and consistent bent parts, it is important to carefully measure and consider the arc length and the distance between the neutral axis and the bend line. You should also use an accurate bend allowance appropriate to the material and thickness being bent, as well as the type of bending process being used (for example, air bending, bottom bending, or stamping).

Xuanmin provides metal stamping and bending services for materials such as carbon steel, stainless steel, copper/brass, aluminum and titanium. The process includes mold making, deep stamping, surface treatment (polishing, sandblasting, painting, coating, electroplating, etc.), assembly (if required), packaging, test report, quality inspection report and sea or air transportation. Standard export packaging ensures safe delivery.

At Xuanmin Technology, we provide high-precision, fast and high-quality sheet metal bending and manufacturing services, and we can also perform post-processing according to your requirements. To get a quote, please upload your model in our real-time quote engine.