Products

Plastic injection Molding

Injection mold manufacturing and injection molding service information | |

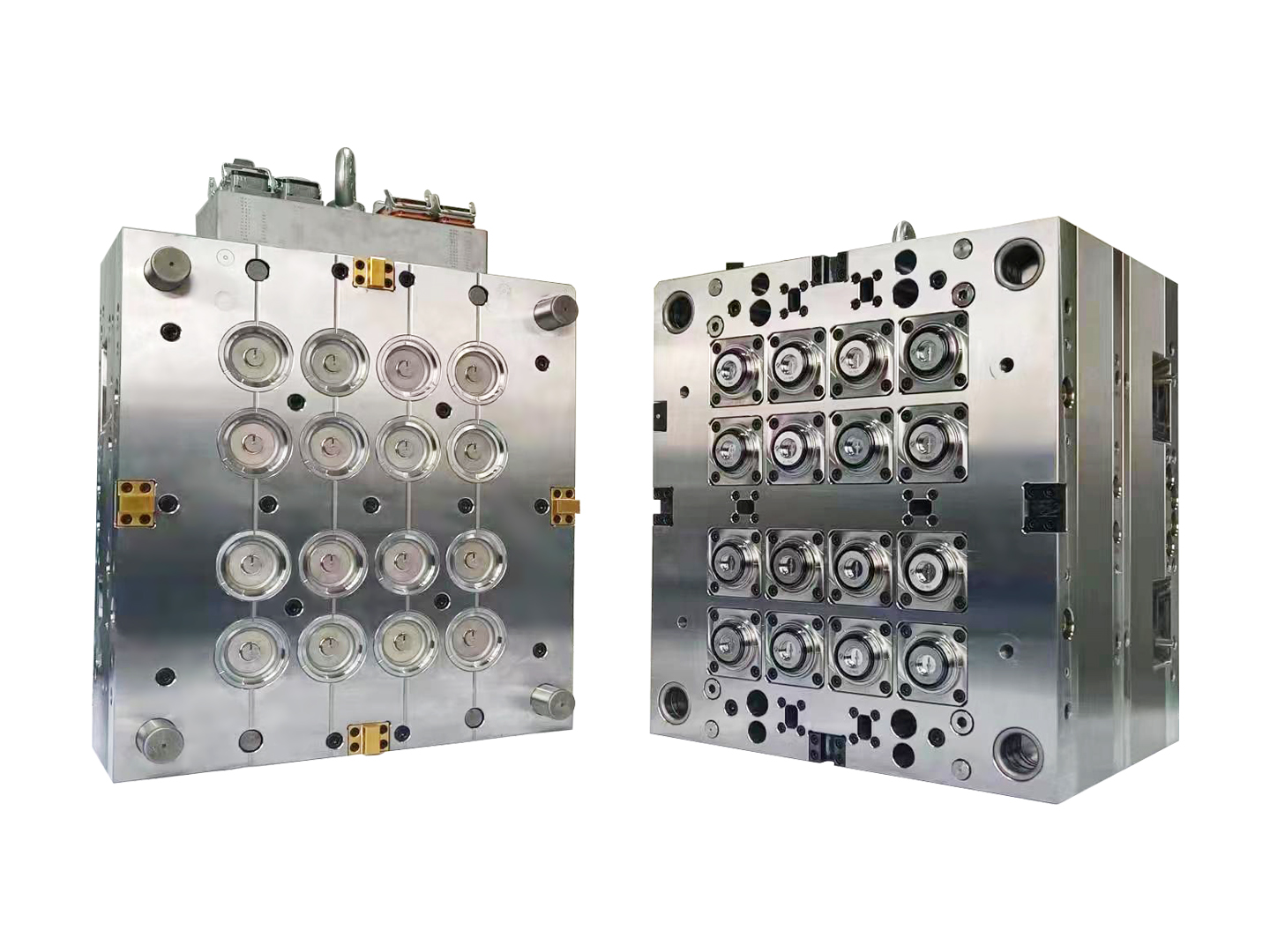

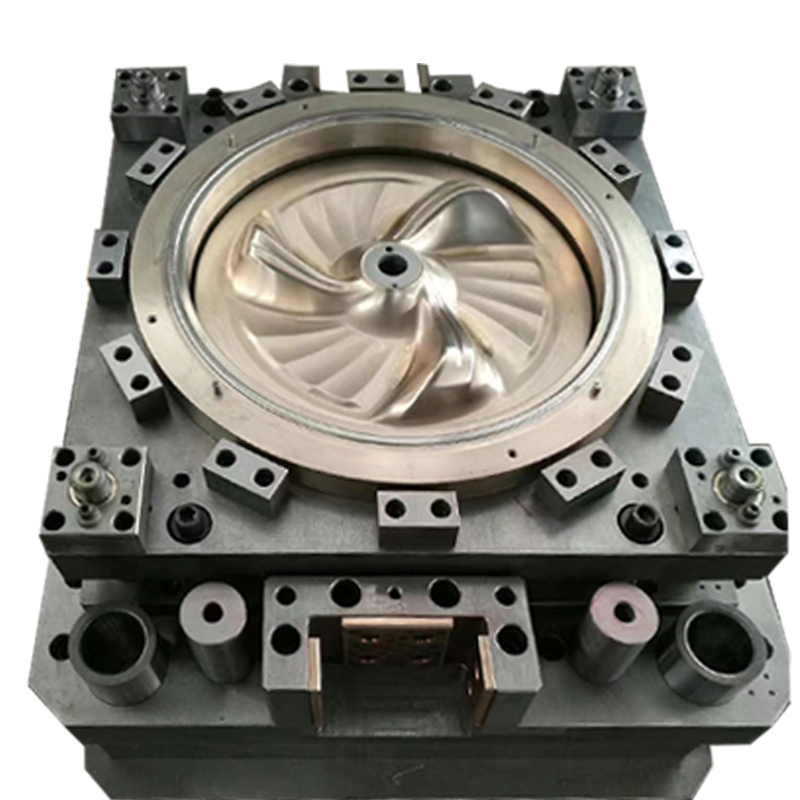

Name | Injection Mold |

Size | Customization |

Mold Type | Injection mold, injection molding ,multi-cavities mold |

Production time | 30-45 days |

Gating System | Hot runner, cold runner, as required |

Mold material

| SKD61(Optional raw material:P20、718、718H、NAK80、S136、S136H) |

Manufacturing procedure | CNC\EDM\WEDM\Milling Machine\Grinding Machine... |

Surface treatment

| High glossy surface (optional process: ordinary smooth surface, etched surface) |

Forming processes: | Injection |

Forming Materia | PE(Optional raw material:PE\PMMA\PC\PS\PA\PVC\ABS\PP\POM\PBT...) |

Capacity | 1 million pieces per month |

Service | Customized by customer's requirements, provide a complete set of solutions for mold design , production , injection . |

Application | Blood test tube,syringe, safety goggles,Home appliances housing,Bottom plate,packing pot,Medical instrument housing,Monitor housing,audiphone,Electronic communication parts,Phone shell, audio shell |

Keywords :

plastic injection mold , plastic injection tooling , plastic injection die , injection molding ,injection molding parts , plastic mold factory , injection molding service .

Descriptions :

Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. It works by injecting molten materials into a mould ,t is typically used as a mass production process to manufacture thousands of identical items. Injection moulding materials include metals, glasses, elastomers and confections, although it is most commonly used with thermoplastic and thermosetting polymers.

When is Injection Moulding Used?

Injection moulding is used to make a range of widely used products, including common plastic items like bottle tops as well as remote control casings, syringes and more. It is also commonly used for manufacturing larger items such as car body panels.

Injection moulding is mainly used where there is a need to manufacture many thousands or millions of identical parts from a mould.