Metals are materials that have a lustrous appearance when newly worked, polished, or broken. They have excellent thermal and electrical conductivity, as well as the properties of being ductile (able to be hammered into thin sheets) and malleable (able to be drawn into wire). Most metals are solid at room temperature and have a distinctive silvery sheen—but mercury is an exception, existing as a liquid.

In CNC machining, commonly used metal materials include aluminum alloy, stainless steel, titanium alloy, copper, brass, zinc alloy, nickel alloy, tungsten alloy, iron, cast iron, etc. These materials have their own characteristics and play different roles in different engineering projects.

Here is a brief introduction to 10 metal materials and their applications

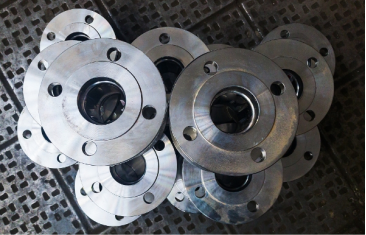

Stainless steel

In the early 20th century, stainless steel was introduced to the field of product design. Designers developed many new products based on its toughness and corrosion resistance, involving many areas that had never been explored before. This series of design attempts was very revolutionary: for example, equipment that could be reused after disinfection appeared in the medical industry for the first time.

Stainless steel has corrosion resistance and high temperature strength. Its strength and corrosion resistance are highly favored, so it is widely used in CNC processing to manufacture kitchenware, medical equipment, chemical containers, etc. Its oxidation resistance and easy cleaning make stainless steel the material of choice for the food and medical industries.

Zinc

with its silvery luster and bluish-grey hue, is the third most widely used nonferrous metal after aluminum and copper. Zinc has a very low melting point, so it is also an ideal casting material.

Zinc castings are very common in our daily lives: doorknobs, faucets, electronic components, etc. Zinc has a very high corrosion resistance, which makes it have another basic function, that is, as a surface coating material for steel. In addition to the above functions, zinc is also an alloy material that combines with copper to form brass. Its corrosion resistance is not only used for steel surface coating - it also helps to strengthen our human immune system.

Typical uses: electronic components. Zinc is one of the alloy materials that form bronze. Zinc also has the characteristics of cleanliness and corrosion resistance. In addition, zinc is also used in roofing materials, photo engraving plates, mobile phone antennas and shutter devices in cameras.

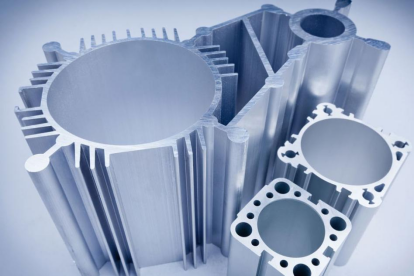

Aluminum alloy

Aluminum alloy is a lightweight and high-strength metal material with good thermal conductivity and corrosion resistance.

Material properties: flexible and ductile, easy to make alloys, high strength-to-weight ratio, excellent corrosion resistance, easy to conduct electricity and heat, recyclable.

Applications: vehicle frames, aircraft parts, kitchen utensils, packaging and furniture. Aluminum is also often used to reinforce some large building structures, such as the Eros statue in London's Piccadilly Circus and the top of the Chrysler Building in New York, which have all used aluminum reinforcement materials.

Magnesium

Magnesium is an extremely important nonferrous metal. It is lighter than aluminum and can form high-strength alloys with other metals. Magnesium alloys have the advantages of light weight, high specific strength and specific stiffness, good thermal conductivity and electrical conductivity, good damping and electromagnetic shielding performance, easy processing and molding, and easy recycling. Magnesium is the lightest structural metal widely used by precision processing service providers. It has excellent machinability, strength and durability, making it very suitable for applications in multiple industrial fields.

Typical uses: Widely used in aerospace, automobile, electronics, mobile communications, metallurgy and other fields.

chromium

The most common form of chromium is as an alloying element in stainless steel to enhance the hardness of stainless steel. Chromium plating is widely used in the engineering field. Decorative chromium plating is usually plated on the outside of the nickel layer as the top layer. The plating has a delicate and mirror-like polishing effect.

Material properties: Very high finish, excellent corrosion resistance, hard and durable, easy to clean, low friction coefficient.

Typical uses: Decorative chrome plating is the coating material for many automotive components, including door handles and buffers. In addition, chrome is also used in bicycle parts, bathroom faucets, furniture, kitchen utensils, tableware, etc. Hard chrome plating is more used in the industrial field, including random access memory in job control blocks, jet engine components, plastic molds and shock absorbers. Black chrome plating is mainly used for musical instrument decoration and solar energy utilization.

Titanium

Titanium is a very special metal, very light, yet very tough and corrosion-resistant, and it maintains its color throughout its life at room temperature. The melting point of titanium is similar to that of platinum, so it is often used in aerospace and military precision parts. After adding electric current and chemical treatment, it will produce different colors.

Typical uses: golf clubs, tennis rackets, laptops, cameras, luggage, surgical implants, aircraft frames, chemical tools, and maritime equipment. In addition, titanium is also used as a white pigment for paper, painting, and plastics.

Carbon

Carbon steel is a metal material with high strength and hardness. It is widely used in the manufacture of mechanical parts and tools due to its durability, safety, long shelf life, affordability and environmentally friendly properties. In CNC machining, carbon steel can be used to make automotive parts, building structures, cutting tools, etc. Its wear resistance and plasticity make carbon steel the material of choice in the engineering industry.

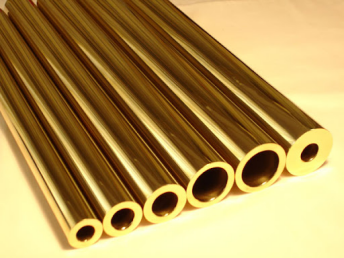

Brass

Brass is an alloy material with good electrical and thermal conductivity. In CNC machining, brass is often used to make electrical connectors, instruments and meters, and bathroom accessories. Its low magnetism and toughness make brass the material of choice in the electronics and construction industries.

Cemented carbide

Cemented carbide has high hardness, strength, wear resistance and corrosion resistance. It is widely used as tool materials, such as turning tools, milling cutters, planers, drill bits, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel. It can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-process materials. It is widely used in military industry, aerospace, mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, construction and other fields.

Inconel

It is a nickel-based high-temperature alloy that has gained popularity in recent years due to its many beneficial properties. Inconel parts are suitable for environments where they may be subject to water corrosion or oxidation. It is also very suitable for applications where the parts may be subjected to extreme pressure and heat. It is widely used in aviation, aerospace, petrochemical and other fields.

At Xuanmin, you can easily find the metal materials and related products you need, whether for industry, construction, decoration, food processing, or other fields, we can meet your needs.

We provide products in a variety of specifications and sizes, and support customized services to meet the personalized needs of different customers. Please contact us now!